HEAVY LIFT!

Straining or crushing

injury may occur from

improperly lifting the

machine or some of its

parts. To reduce this

risk, get help from other

people and use a forklift

(or other lifting equip-

ment) rated for weight of

machine.

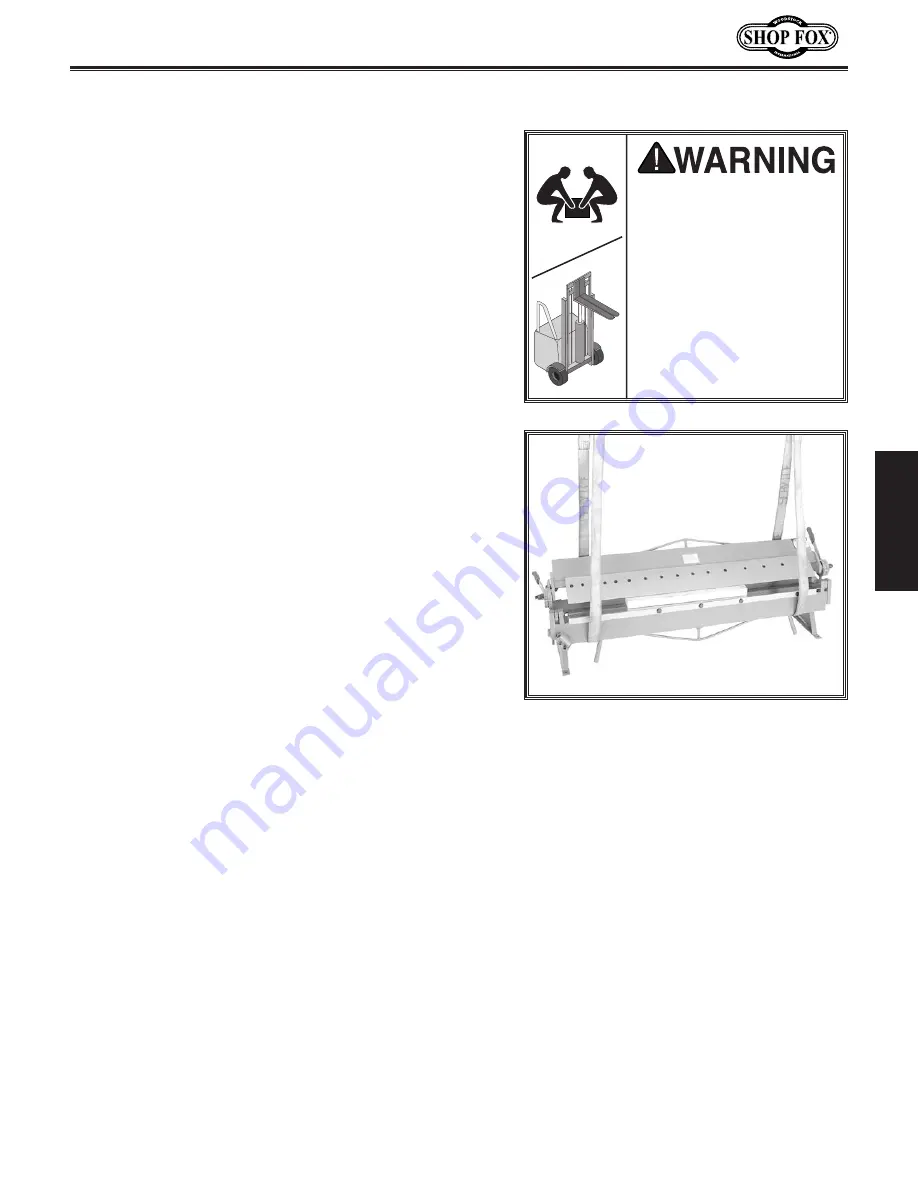

Figure.9..

Example of pan & box brake

supported by lifting straps and 2x4 to

secure clamping leaf.

-13-

Model M1118 (For Machines Mfd. Since 09/21)

SE

TU

P

Lifting.&.Placing

Use a forklift to lift the machine off the pallet and onto a

suitable location.

To.lift.and.place.machine,.do.these.steps:

1..

Using a forklift, move crate to machine work site

location.

2..

Remove crate top and sides, components inside

crate, and blocks around machine base.

3..

Remove fasteners securing machine to base.

4..

Secure clamping leaf by inserting a wood 2x4

between clamping leaf and bending block (see

Figure.9

).

5..

Use forklift to raise machine, then place onto

workbench.

6..

Fasten machine to workbench following instructions

in

Bench.Mounting.

on

Page.14

.