-12-

Three handles are supplied for drilling opera-

tions.

NOTE:

remove these handles when you

use the oscillating feature.

To install the handles, do these steps:

1.

Thread the handles into the hub as shown

in

Figure 14.

2.

Tighten the handles until they are snug,

DO NOT

over-tighten.

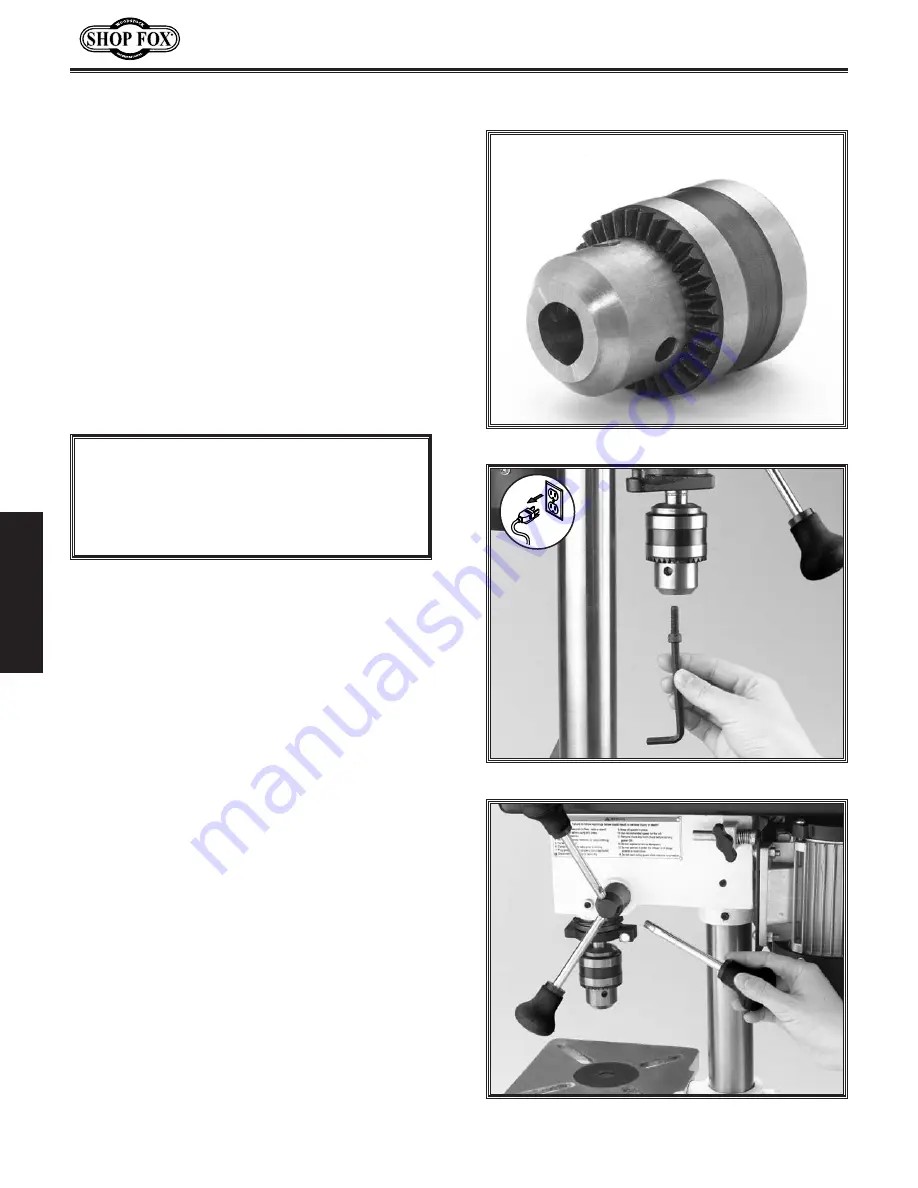

Figure 14.

Installing spindle handles.

Figure 13.

Inserting the caps crew.

Figure 12.

Jaws adjusted inside chuck body.

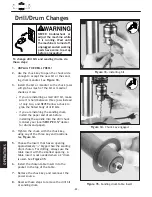

The drill chuck is seated to the spindle with a

JT-33 tapered surface and a screw.

To install the drill chuck, do these steps:

1.

Clean the drill chuck and spindle with min-

eral spirits and follow all safety warnings

on the container. Failure to clean the

tapered-mating surfaces of the spindle and

drill chuck will result in the chuck falling

off during use.

2.

Use the provided chuck key to adjust the

jaws of the chuck until they are well inside

the drill chuck body. See

Figure 12.

3.

Place the drill chuck on the spindle, and

insert the cap screw into the hole of the

drill chuck. See

Figure 13.

4.

Tighten the cap screw so the drill chuck is

seated securely on the spindle.

• If the chuck fails to remain secure on the

spindle, repeat

Step 1, DO NOT use a

hammer to seat the drill chuck onto the

spindle!

NOTICE

DO NOT use a hammer to seat the drill

chuck onto the spindle. You will damage

the oscillating mechanism.

ASSEMBLY

Handles

Drill Chuck

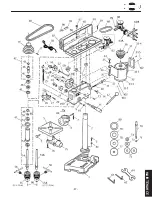

Summary of Contents for SHOP FOX W1667

Page 21: ... 19 ADJUSTMENTS ...

Page 22: ... 20 ADJUSTMENTS ...

Page 29: ... 27 Parts Diagram MAINTENANCE ...

Page 35: ......

Page 36: ......