-19-

Model W1686 (For Machines Mfd. Since 11/10)

SE

TU

P

4..

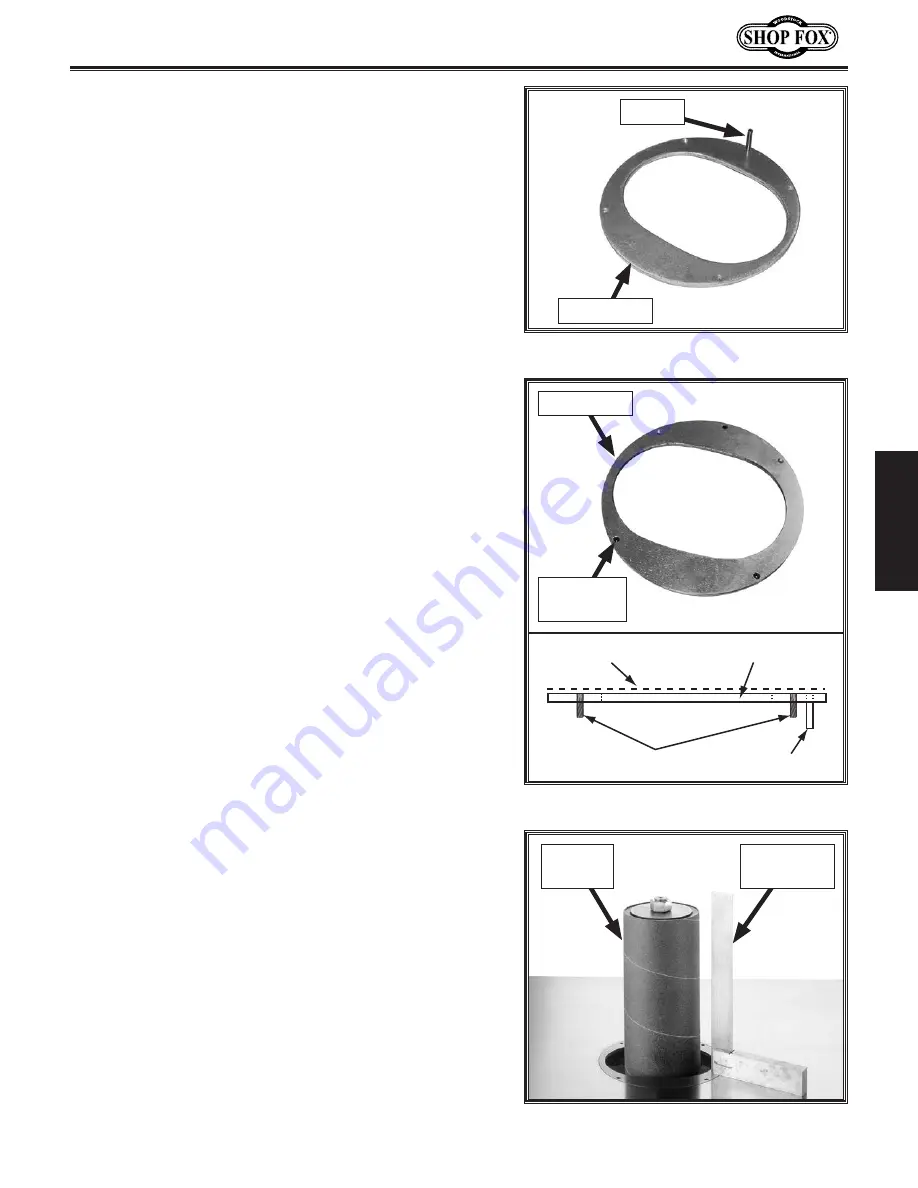

Insert one 3 x 20mm roll pin into non-threaded hole

in each of three table inserts, as shown in

Figure.

15

. Make sure it does not extend through surface of

table insert.

6. Using a machinist's square, bring table surface

square to spindle surface, as shown in

Figure

17

.

Note:

It may be necessary to thread the table stop

bolt further into the base in order to make the

table square to the spindle.

7. Move square to various points around table to ensure

table and spindle are square on all sides. Adjust stop

bolt as necessary until table rests on stop bolt and is

square with spindle.

8. Re-tighten jam nut to secure table stop bolt.

9. Tighten both tilt lock levers when you are satisfied

with position of table.

10. Loosen retainer screw (see

Figure

14

) that secures

scale pointer and adjust pointer to read 0˚.

Re-tighten retainer screw.

Figure.15.

Inserting roll pins (bottom view).

Roll Pin

Table Insert

Figure.17.

Checking table for square.

Machinist's

Square

Spindle

Surface

Figure.16.

Inserting set screws.

Table Insert

Set Screw

(1 of 4)

Flat Top Surface

Set Screws

Roll Pin

Table Insert

5.

Thread four

1

⁄

4

"-20 x

5

⁄

8

" set screws into threaded

holes in each table insert, as shown in

Figure.16

.

Note:.

The roll pins and set screws must not

protrude above the top surface of the table insert

or they will interfere with sanding operations.

Summary of Contents for Shop Fox W1686

Page 41: ...Model W1686 For Machines Mfd Since 11 10...

Page 44: ......