-37-

Model 1686 (For Machines Mfd. Since 11/10)

PA

RT

S

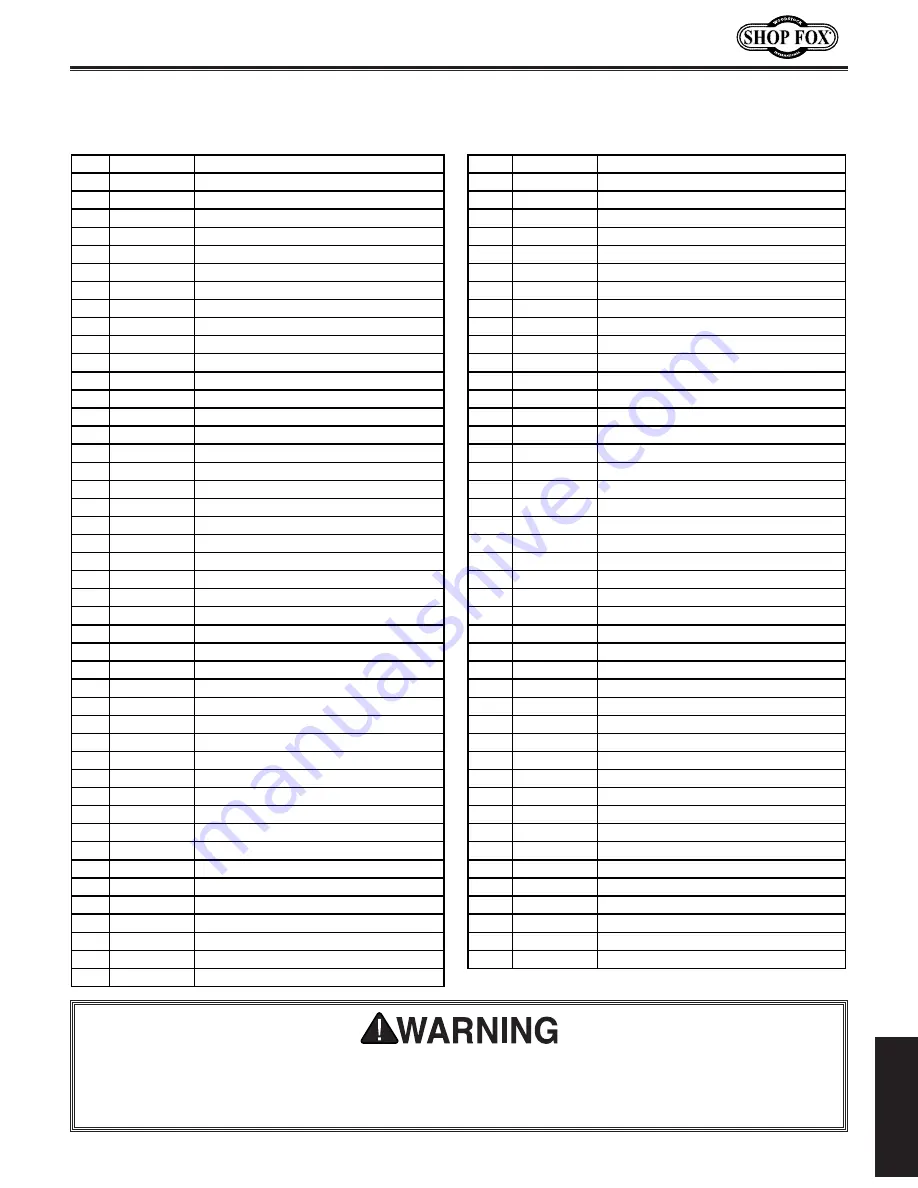

Main.Parts.List

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

2

X1686002

CAP SCREW 5/16-18 X 1

85

X1686085

STRAIN RELIEF TYPE-3 M20-1.5

5

X1686005

SHOP FOX NAMEPLATE-MEDIUM

86

X1686086

MOTOR 1HP 120V/240V 1PH

6

X1686006

INSERT 4-1/4" X 6"

86-1

X1686086-1 MOTOR FAN COVER

7

X1686007

DUST COVER

86-2

X1686086-2 MOTOR FAN

8

X1686008

KEY 5 X 5 X 25

86-3

X1686086-3 CONTACT PLATE

11

X1686011

TABLE

86-4

X1686086-4 MOTOR JUNCTION BOX

12

X1686012

INSERT, 1-3/4" X 2-3/16"

86-5

X1686086-5 CENTRIFUGAL SWITCH

13

X1686013

INSERT, 2-3/16" X 3-1/2"

86-6

X1686086-6 S CAPACITOR 300M 125V

14

X1686014

BRACKET

86-7

X1686086-7 BALL BEARING 6204ZZ (FRONT)

15

X1686015

TRUNNION

86-8

X1686086-8 BALL BEARING 6202ZZ (REAR)

16

X1686016

INNER TRUNNION

90

X1686090

HEX BOLT 3/8-16 X 1-1/4

17

X1686017

4" DUST CHUTE

91

X1686091

HEX BOLT 3/8-16 X 1

18

X1686018

HOUSING CASTING

92

X1686092

LOCK WASHER 3/8

19

X1686019

DIPSTICK

93

X1686093

SET SCREW 1/4-20 X 5/8

20

X1686020

SPINDLE CASTING

94

X1686094

ROLL PIN 5 X 28

21

X1686021

COVER

95

X1686095

FLAT WASHER 3/8

22

X1686022

SPINDLE

96

X1686096

HEX NUT 5/16-18

23

X1686023

SPINDLE KEY 5 X 5 X 20

97

X1686097

CAP SCREW 10-32 X 3/8

24

X1686024

SPINDLE RETAINER

98

X1686098

HEX BOLT 3/8-16 X 1-1/2

25

X1686025

SPINDLE NUT

99

X1686099

HEX NUT 3/8-16

26

X1686026

WORM

100

X1686100

CAP SCREW 5/16-18 X 1

27

X1686027

MOUNTING BRACKET

101

X1686101

LOCK WASHER 5/16

28

X1686028

BEARING BLOCK

102

X1686102

CAP SCREW 3/8-16 X 3/4

29

X1686029

WORM GEAR 24T

103

X1686103

HEX BOLT 3/8-16 X 1-1/4

30

X1686030

CONNECTING ROD

104

X1686104

BALL BEARING 6206ZZ

31

X1686031

WRIST PIN

105

X1686105

SEAL 30-62-8

32

X1686032

DRIVE SHAFT

106

X1686106

INT RETAINING RING 62MM

33

X1686033

HUB

107

X1686107

BALL BEARING 6205-2RS

34

X1686034

CENTER BLOCK

108

X1686108

CAP SCREW 5-40 X 1/2

35V2 X1686035V2 CASE V2.08.02

109

X1686109

ROLL PIN 5 X 30

35-1 X1686035-1 RUBBER STRIP

110

X1686110

KEY 5 X 5 X 25

45

X1686045

GUIDE SHAFT

111

X1686111

SET SCREW 5/16-18 X 3/8

64

X1686064

TABLE STOP BOLT 3/8-16 X 6-1/2

112

X1686112

DRAIN PLUG

70

X1686070

POINTER

113

X1686113

HEX NUT 5/8-11

71

X1686071

POINTER MOUNT

114

X1686114

LOCK WASHER 5/8

72

X1686072

CABINET

117

X1686117

HEX BOLT 5/16-18 X 1

75

X1686075

DOOR

118

X1686118

FENDER WASHER 5/16

76

X1686076

LOCK HANDLE

122

X1686122

PHLP HD SCR 10-24 X 1

77

X1686077

SCALE

123V2 X1686123V2 MACHINE ID LABEL V2.11.10

78

X1686078

RIVET

124

X1686124

SAFETY GLASSES LABEL

79

X1686079

OIL BREATHER

125

X1686125

READ MANUAL LABEL

80

X1686080

KNOB 1/4"-20 X 1"

126

X1686126

ELECTRICITY LABEL

81

X1686081

GASKET

128

X1686128

DAMPNESS EXPOSURE LABEL

82

X1686082

SHOP FOX PADDLE SWITCH 125V/250V

129

X1686129

CHECK OIL LABEL

83V2 X1686083V2 MOTOR CORD 16AWG 3W 30" V2.11.10

130

X1686130

TAP SCREW M3 X 10

84V2 X1686084V2 PWR CORD 16AWG 3W 5-15P V2.11.10

Safety.labels.warn.about.machine.hazards.and.how.to.prevent.serious.personal.injury..The.owner.

of.this.machine.MUST.maintain.the.original.location.and.readability.of.all.labels.on.this.machine..

If.any.label.is.removed.or.becomes.unreadable,.REPLACE.that.label.before.allowing.machine.to.

be.operated.again..Contact.us.at.

(

360

)

.734-3482.or.www.woodstockint.com.to.order.new.labels..

Summary of Contents for Shop Fox W1686

Page 41: ...Model W1686 For Machines Mfd Since 11 10...

Page 44: ......