-30-

W1758 Owner's Manual (Mfg. Since 4/10)

SE

RV

IC

E

Troubleshooting

This section covers the most common problems and corrections with this type of

machine.

WARNING! DO NOT make any adjustments until power is disconnected and

moving parts have come to a complete stop!

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Lathe will not start, or it

growls on start up.

1. Power supply fuse or circuit break-

er has tripped.

2. Motor fan cover is dented, stop-

ping the fan from being able to

spin.

3. Paddle switch is broken or faulty.

4. Start capacitor is at fault.

5. Motor is at fault.

1. Disconnect power, and inspect circuit for electrical

shorts and repair. Replace circuit breaker if it is

old or has tripped many times.

2. Replace or adjust fan cover; inspect motor fan and

replace if damaged.

3. Disconnect power, and use an ohmmeter to check

switch terminals for continuity, and replace switch

if required.

4. Replace start capacitor.

5. Replace motor.

Fuses or circuit breakers

trip open.

1. Short circuit in line cord or plug.

2. Short circuit in motor or loose

connections.

3. Incorrect fuses or circuit breakers

in power supply.

1. Inspect cord or plug for damaged insulation and

shorted wires, and replace extension cord.

2. Replace or adjust fan cover; inspect motor fan and

replace if damaged.

3. Install correct fuses or circuit breakers.

Vibration noise while

machine is running; noise

changes when speed is

changed.

1. V-belt cover loose.

2. V-belt cover bent or dented and is

making contact with motor pulley

or V-belt.

3. Bad spindle bearing(s).

1. Tighten the four screws securing V-belt cover;

if necessary, install a soft, vibration dampening

material between V-belt cover and headstock.

2. Remove V-belt cover and inspect for dents, bends,

or indications of rubbing. Tap out dents with rub-

ber mallet, bend back into proper shape, or shim

away from the motor pulley.

3. Replace spindle bearing(s).

Vibration noise while

machine is running; noise

remains constant when

speed is changed.

1. Dented motor fan cover.

2. Bad spindle bearing(s).

1. Replace or adjust fan cover; inspect motor fan and

replace if damaged.

2. Replace spindle bearing(s).

Troubleshooting

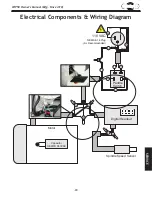

Motor & Electrical