-31-

W1772/W1773 37" Drum Sander

M

A

IN

TE

N

A

N

CE

Figure

35

. Table lift screws (table

removed for clarity).

Figure

36

. Worm gear threads.

Failure to routinely inspect your drum sander for

damage and wear could result in unsatisfactory work

results, premature component or machinery failure,

or operator injury. We recommend you create a

checklist for routine inspection and maintenance.

Remember to always disconnect the drum sander

from its power source before attempting to inspect,

adjust, or repair this machine!

2.

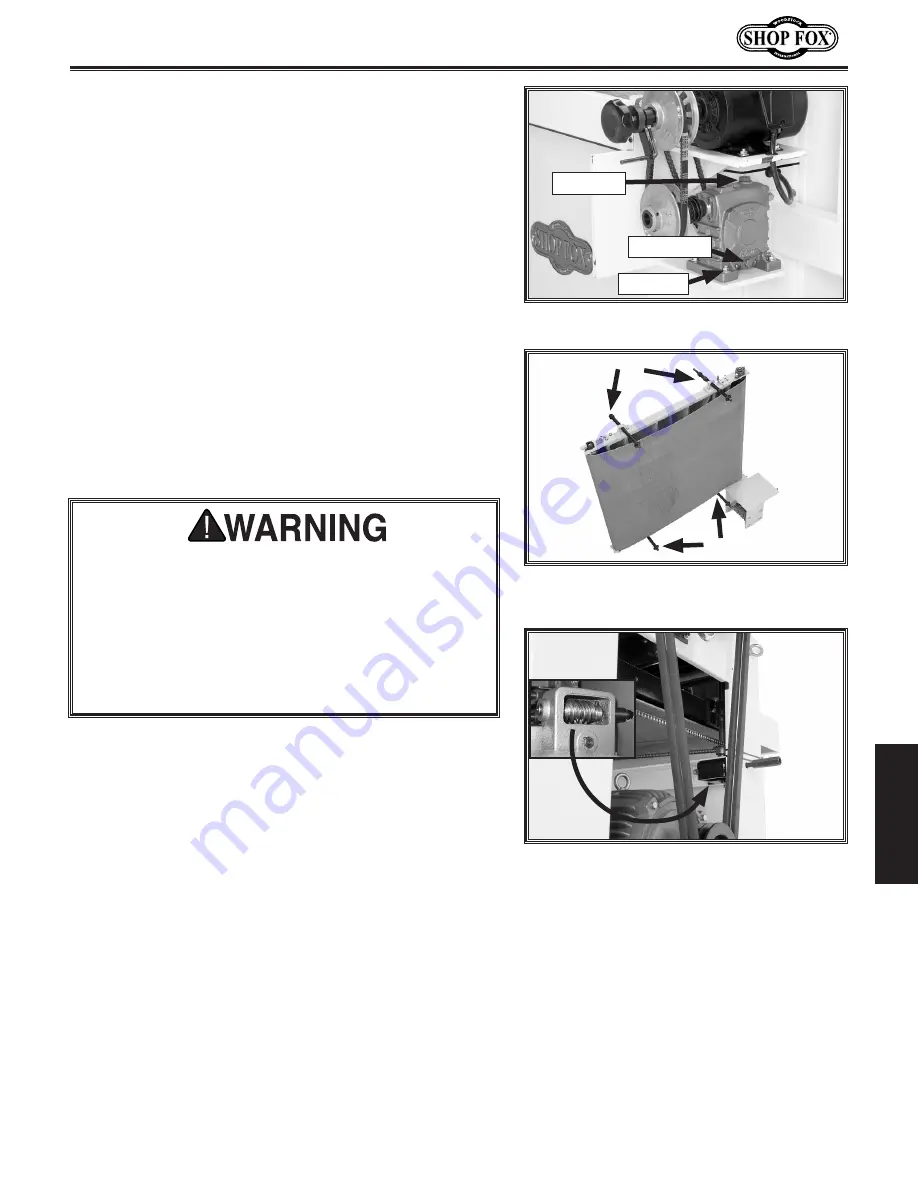

Remove the feed motor cover, loosen the four hex

bolts (

Figure 34

) that secure the gear box to the

motor bracket, and remove the V-belt.

3.

With the oil and gearbox warm, slide the gearbox

out, remove the fill plug (

Figure 34

), remove the

drain plug

,

drain the oil, and reinstall the drain

plug.

4.

Add new oil, reinstall the fill plug, then reinstall the

gearbox, cover, and other components removed in

Step 1

.

Table Lift Screws

: Should be cleaned with mineral spirits

and painted with lithium grease every six months. Then,

move the table up or down to spread the grease thor-

oughly over the threads. Do not overlubricate.

Worm Gear

: Paint a light coat of lithium grease on the

worm gear threads (

Figure 36

) once a year.

Figure

34

. Lubricating gear box.

Fill Plug

Drain Plug

Hex Bolt

Summary of Contents for SHOP FOX W1772

Page 2: ......

Page 5: ...3 W1772 W1773 37 Drum Sander INTRODUCTION...

Page 6: ...4 W1772 W1773 37 Drum Sander INTRODUCTION...

Page 7: ...5 W1772 W1773 37 Drum Sander INTRODUCTION...

Page 8: ...6 W1772 W1773 37 Drum Sander INTRODUCTION...

Page 62: ...60 W1772 W1773 37 Drum Sander PARTS Conveyor Parts Breakdown...

Page 66: ...64 W1772 W1773 37 Drum Sander PARTS Electrical Components...

Page 72: ......