Model W1783 (Mfg. Since 2/07)

-13-

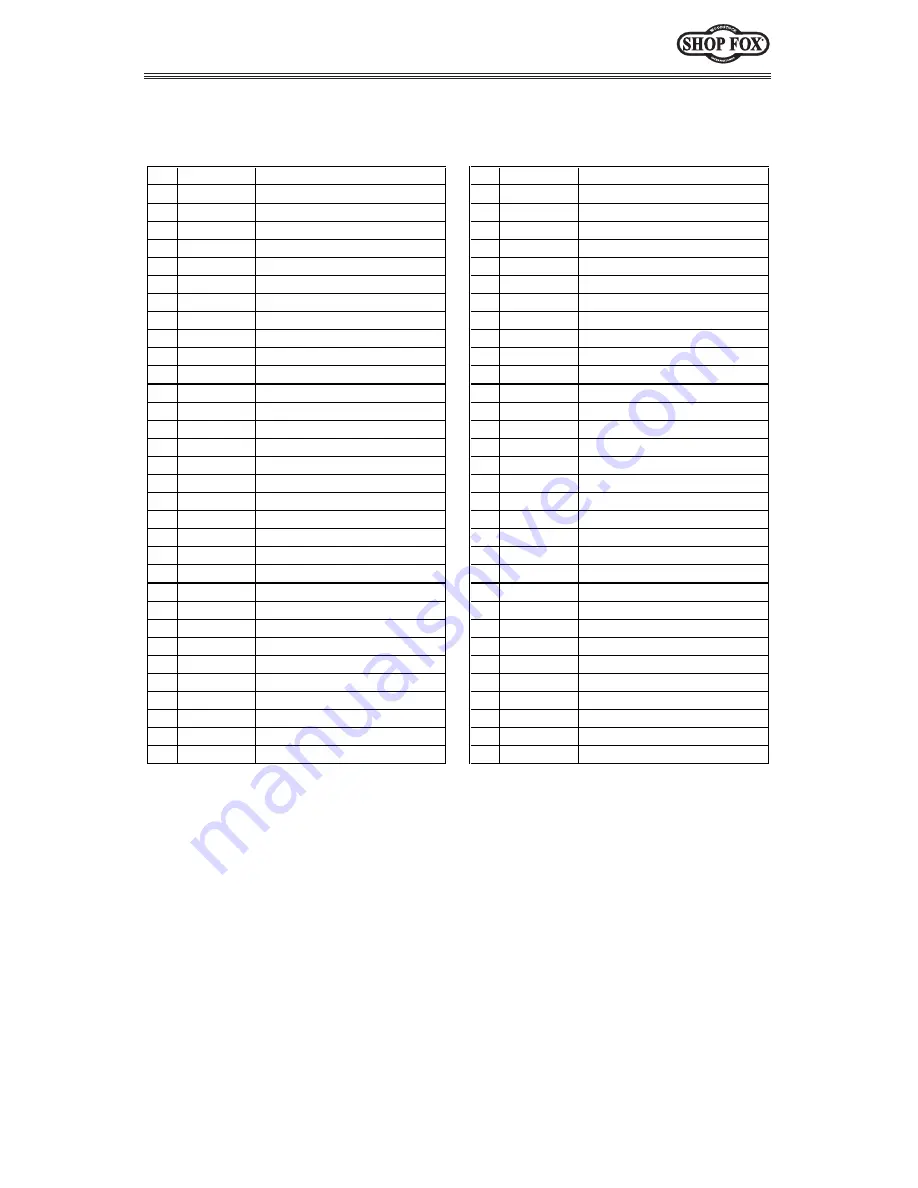

PARTS LIST

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

1

X1783001

CYLINDER

38 XPW01M

FLAT WASHER 8MM

3

X1783003

BUMPER

39 X1783039

L-BOLT

4

XPORP050 O-RING 49.7 X 3.5 P50

40 X1783040

STOPPER

5

X1783005

DRIVER

41 XPS38M

PHLP HD SCR M4-.7 X 10

6

XPRP07M

ROLL PIN 6 X 20

42 X1783042

MAGAZINE SEAT

7

XPSS31M

SET SCREW M5-.8 X 8

43 X1783043

MAGAZINE END CAP

8

X1783008

PISTON POLE

44 XPLN01M

LOCK NUT M4-.7

9

X1783009

PISTON HEAD

45 X1783045

PUSHER SEAT

10 XPORP012-5 O-RING 12.3 X 2.4 P12.5

46 XPRP42M

ROLL PIN 3 X 20

11 X1783011

O-RING 32 X 4.5

47 X1783047

FLAT COIL SPRING

12 X1783012

SEALING SLEEVE

48 X1783048

SPRING BUSHING

13 X1783013

O-RING 12.8 X 1.8

49 X1783049

COMPRESSION SPRING

14 X1783014

SEALING CAP

50 X1783050

PUSHER

15 X1783015

O-RING 15.6 X 1.8

51 XPS07M

PHLP HD SCR M4-.7 X 8

16 X1783016

GUN BODY

52 X1783052

MAGAZINE

17 X1783017

HANDLE GASKET

53 X1783053

NAIL GUIDE

18 X1783018

END CAP

54 X1783054

NAIL GUIDE COVER

19 XPCAP39M CAP SCREW M4-.7 X 20

55 X1783055

DISCHARGE BRACKET

22 X1783022

CYLINDER GASKET

56 XPCAP95M CAP SCREW M5-.8 X 30

23 X1783023

SLEEVE GASKET

57 X1783057

BASE PLATE 1/2" FLOORING

24 XPORP046 O-RING 45.7 X 3.5 P46

58 XPCAP95M CAP SCREW M5-.8 X 30

25 X1783025

PISTON SEAT

59 X1783059

RUBBER BUTTON

26 XPLW02M

LOCK WASHER 4MM

60 X1783060

BASE

27 XPCAP16M CAP SCREW M4-.7 X 16

61 XPW02M

FLAT WASHER 5MM

28 XPS56M

PHLP HD SCR M4-.7 X 16

62 XPFH03M

FLAT HD SCR M6-1 X 40

29 X1783029

EXHAUST COVER

63 X1783063

MALLET

30 X1783030

CYLINDER COVER

64 X1783064

AIR PLUG 1/4 NPT

31 XPSB53M

CAP SCREW M5-.8 X 18

65 X1783065

SAFETY GOGGLES

32 XPORP025 O-RING 24.7 X 3.5 P25

66 XPAW03M

HEX WRENCH 3MM

33 X1783033

WHACK CAP

67 XPAW04M

HEX WRENCH 4MM

34 XPW02M

FLAT WASHER 5MM

68 X1783068

PISTON REPAIR KIT

35 X1783035

HANDLE

69 X1783069

BASE PLATE 3/4" FLOORING

37 XPLN04M

LOCK NUT M8-1.25

70 X1783070

COMPLETE O-RING KIT

Summary of Contents for SHOP FOX W1783

Page 20: ......