Model W1783 (Mfg. Since 2/07)

-5-

The Model W1783 is designed to be

operated at 70-110 PSI using clean,

dry, regulated, compressed air.

Do not

exceed the 120 PSI maximum pressure

for your model.

Before using your nailer, regulate the

air pressure to find the optimum setting

within the specified operating range.

Start by testing the nailer at a low

setting, then increase the air pressure as

needed for satisfactory results.

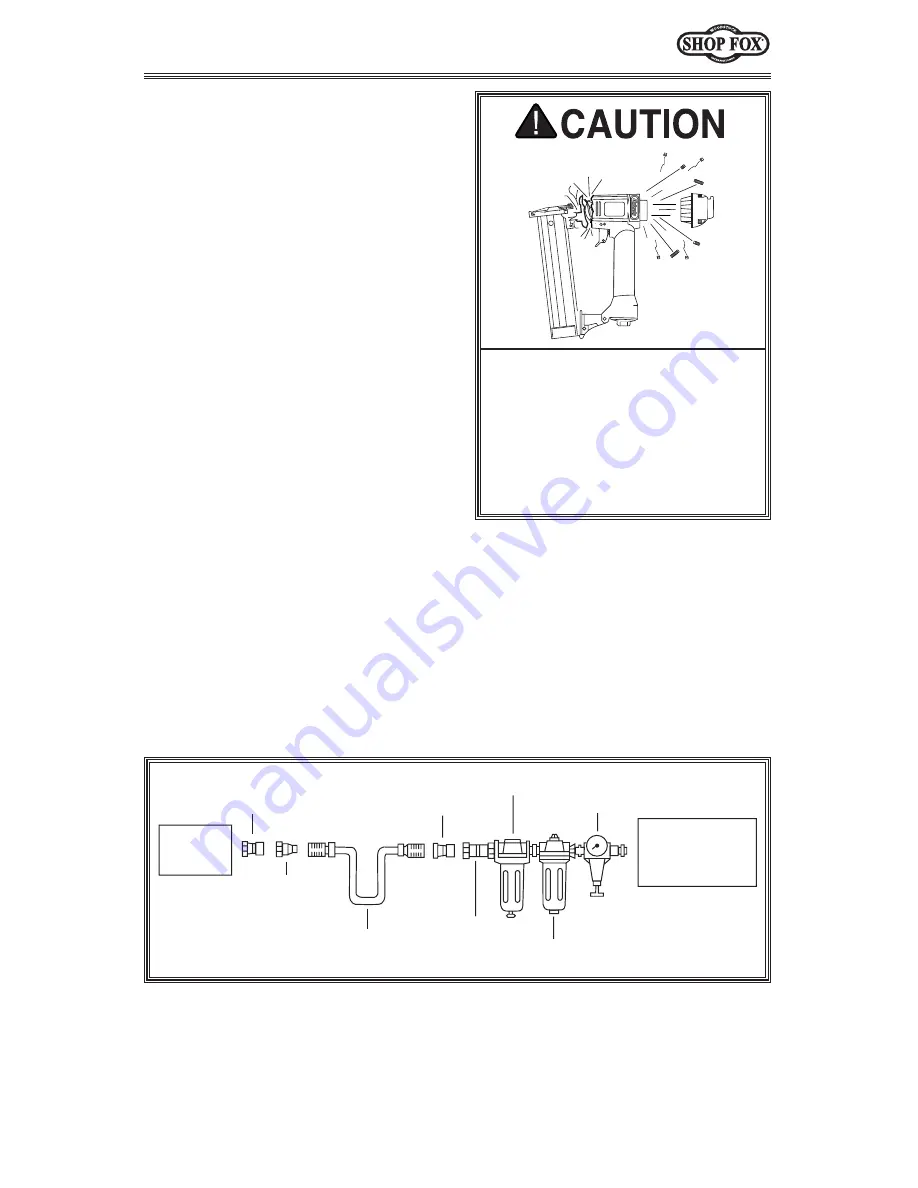

An in-line filter/lubricator/regulator unit

can be installed as depicted in

Figure 1

.

This filter/lubricator/regulator unit

will protect your tool from damaging

water build-up, allow you to adjust and

maintain regulated air pressure, and

save you the inconvenience of having to

manually lubricate your tool every time

you use it.

If you plan on installing a filter/

lubricator/regulator unit in your

compressed air system, always follow the

connection instructions that come with

the unit.

Quick

Connector

Quick

Coupler

Air Hose

Quick

Coupler

Quick

Connector

Lubricator

Filter

Regulator

Air

Compressor

Your

Tool

Figure 1.

Typical filter/lubricator/regulator installation order.

Compressed Air System

Exceeding the maximum permissible

operating pressure may damage the

nailer and cause it to malfunction.

To protect yourself from personal

injury, DO NOT allow the air pressure

to exceed the recommended

pressure for this nailer!

Summary of Contents for SHOP FOX W1783

Page 20: ......