Model W1784 (Mfg. Since 2/07)

-9-

3.

The jammed staple should be visible

in the discharge area.

— If the jammed staple can be

removed with needle nose pliers,

do so and continue to

Step 7

.

— If you cannot remove the jammed

staple, then continue with

Step 4.

4.

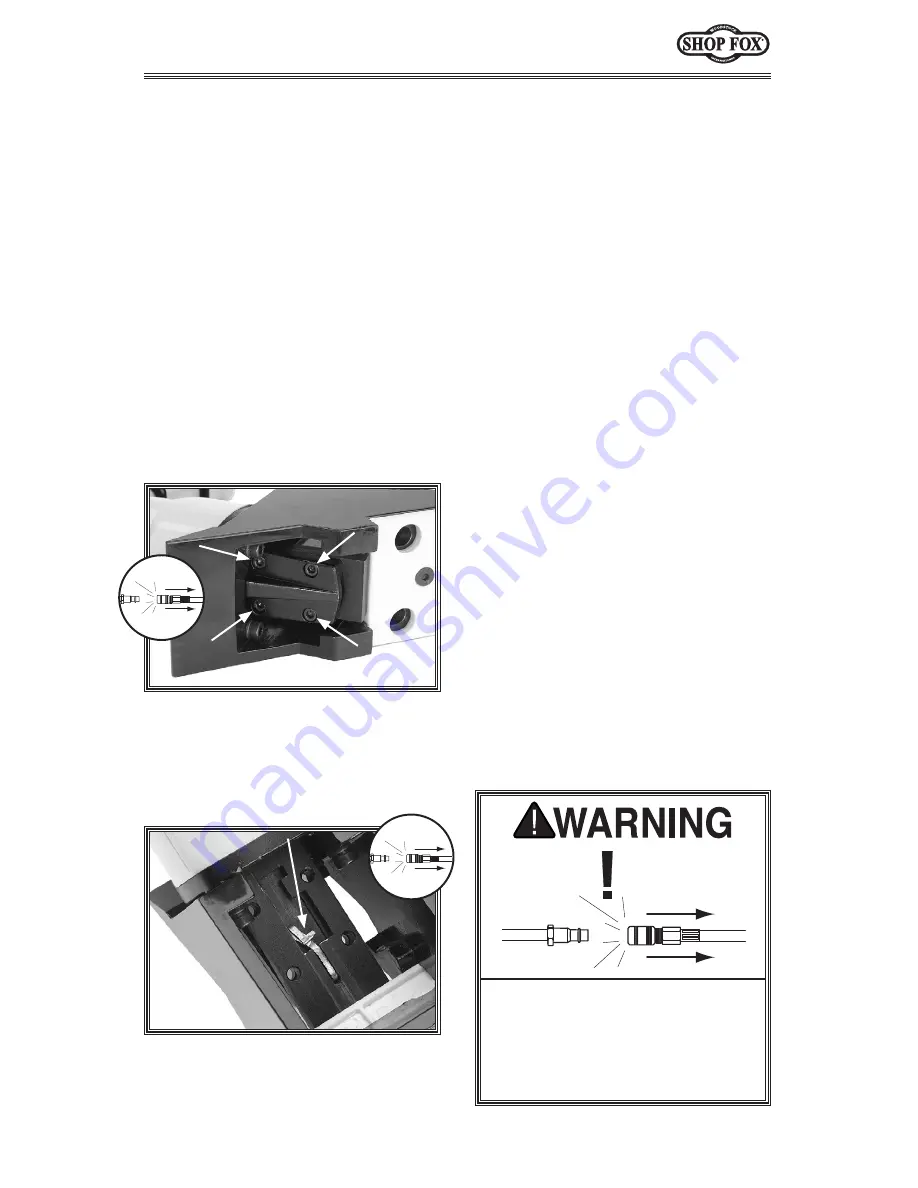

Use the 4mm hex wrench and remove

the four cap screws and lock washers

that secure the magazine to the

stapler (see

Figure 4

).

Note:

It may be necessary to remove

the base plate to pull the magazine

out.

7.

Throw the damaged staple away and

insert a new staple stick that only

contains clean, undamaged staples.

DO NOT use dirty or damaged staples!

Replacing Pistons/

O-Rings

Under heavy use, the piston or O-rings

may wear out. Replacement is quick and

easy. Contact your authorized Shop Fox

dealer to obtain the Piston Repair Kit

(Part Number X1784068) or Complete

O-Ring Kit (Part Number X1784071).

To replace the piston and O-rings, do

these steps:

1.

DISCONNECT STAPLER FROM THE AIR

SUPPLY!

2.

Remove all the staples from the

magazine.

3.

Use the 4mm hex wrench and remove

the four cap screws and lock washers

that secure the magazine to the

stapler (see

Figure 4

).

Note:

It may be necessary to remove

the base plate to pull the magazine

out.

Always disconnect stapler from air

whenever servicing! During main-

tenance, a stapler connected to

air may fire accidentally, causing

serious personal injury!

Figure 4.

Location of cap screws securing

the magazine to the stapler.

5.

Remove the jammed staple from

inside the discharge area with a pair

of need nose pliers (see

Figure 5

).

Figure 5.

Jammed staple in discharge

area.

6.

Re-install the magazine.

Summary of Contents for SHOP FOX W1784

Page 20: ......