-13-

Model W1834 (For Machines Mfd. Since 7/14)

SE

TU

P

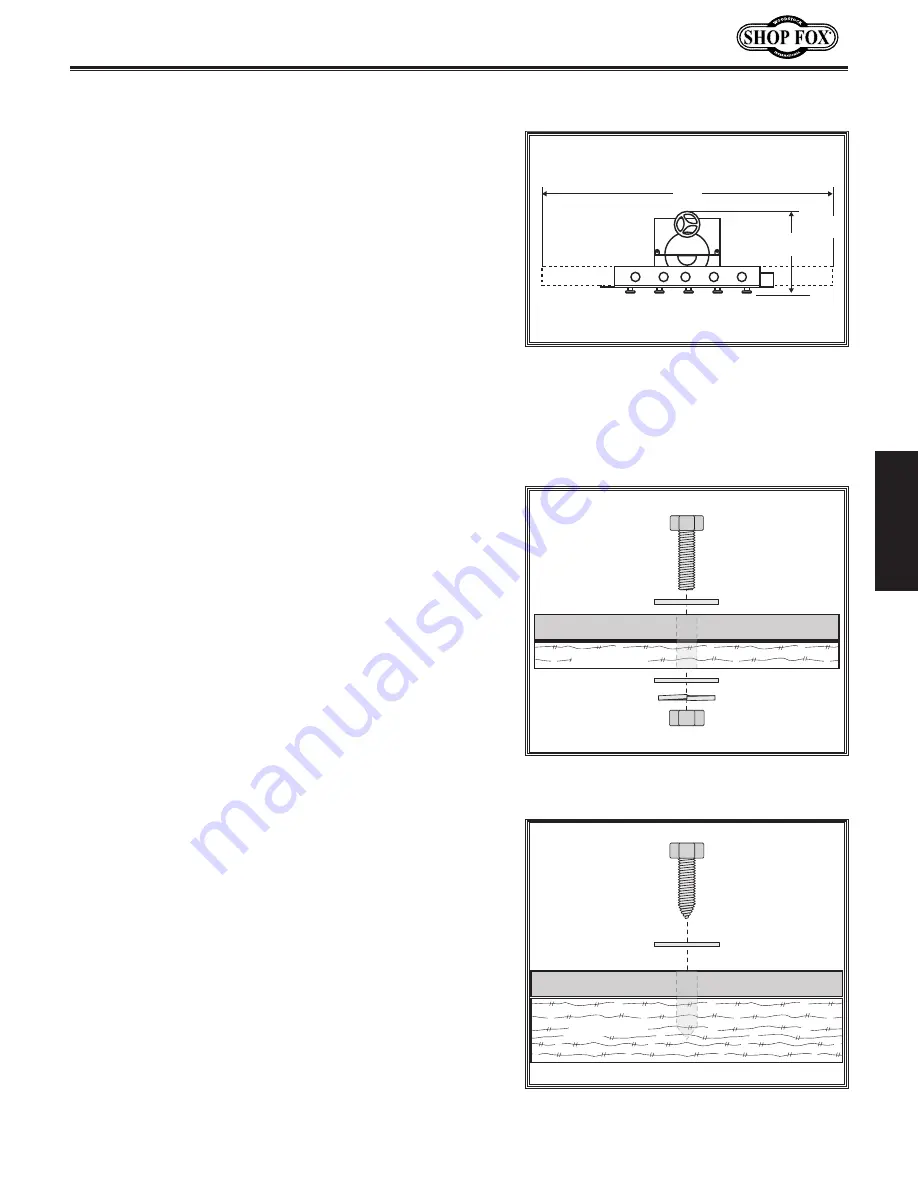

•. Working.Clearances:

Consider existing and

anticipated needs, size of material to be processed

through the machine, and space for auxiliary stands,

work tables, or other machinery when determining

where to locate this machine. See

Figure 4 for the

minimum working clearances

•. Lighting:

Lighting should be bright enough to

eliminate shadow and prevent eye strain.

•. Electrical:.

Electrical circuits must be dedicated or

large enough to handle amperage requirements.

Outlets must be located near each machine, so power

or extension cords are clear of high-traffic areas.

Follow local electrical codes for proper installation of

new lighting, outlets, or circuits.

Machine.Placement

The vibration and forces applied during operation could

cause the grinder to unexpectedly move and greatly

increase the risk of serious personal injury. You MUST

firmly mount your grinder to a stable and flat surface that

will not move during operation.

Note: The rubber feet provide vibration absorption for

the grinder. We recommend that you keep them on the

machine when you mount it to the workbench.

The strongest bench mounting option is a "Through

Mount" where holes are drilled all the way through the

workbench, and hex bolts, washers, and hex nuts are

used to secure the machine to the workbench

(see

Figure

5

).

Another option for mounting is a "Direct Mount" where the

machine is simply secured to the workbench with a lag

screw (see

Figure

6

).

Bench.Mounting

Machine Base

Workbench

Bolt

Flat Washer

Flat Washer

Lock Washer

Hex Nut

Figure.5.

Example of a "Through Mount"

setup.

Figure.6

. Example of a "Direct Mount"

setup.

Machine Base

Workbench

Lag Screw

Flat Washer

Mounting

44"

10"

12"

Figure

4

. Minimum working clearances.