-35-

N(/()Fne\ijDXelXcD]^%j`eZ\*&'0

J<I

M

@:<

J<IM@:<

This section covers the most common service adjustments

or procedures that may need to be made during the life

of your machine.

If you require additional machine service information

not included in this section, please contact Woodstock

International Technical Support at (360) 734-3482 or send

an e-mail to:

k\Z_$jlggfik7j_fg]fo

.

Y`q

.

>\e\iXc

If the feed motor fails, is noisy, warmer than usual, or

appears to run sluggishly, the brushes may need to be

replaced.

To replace feed motor brushes, do these steps:

1.

DISCONNECT THE PLANER/MOULDER FROM POWER!

2.

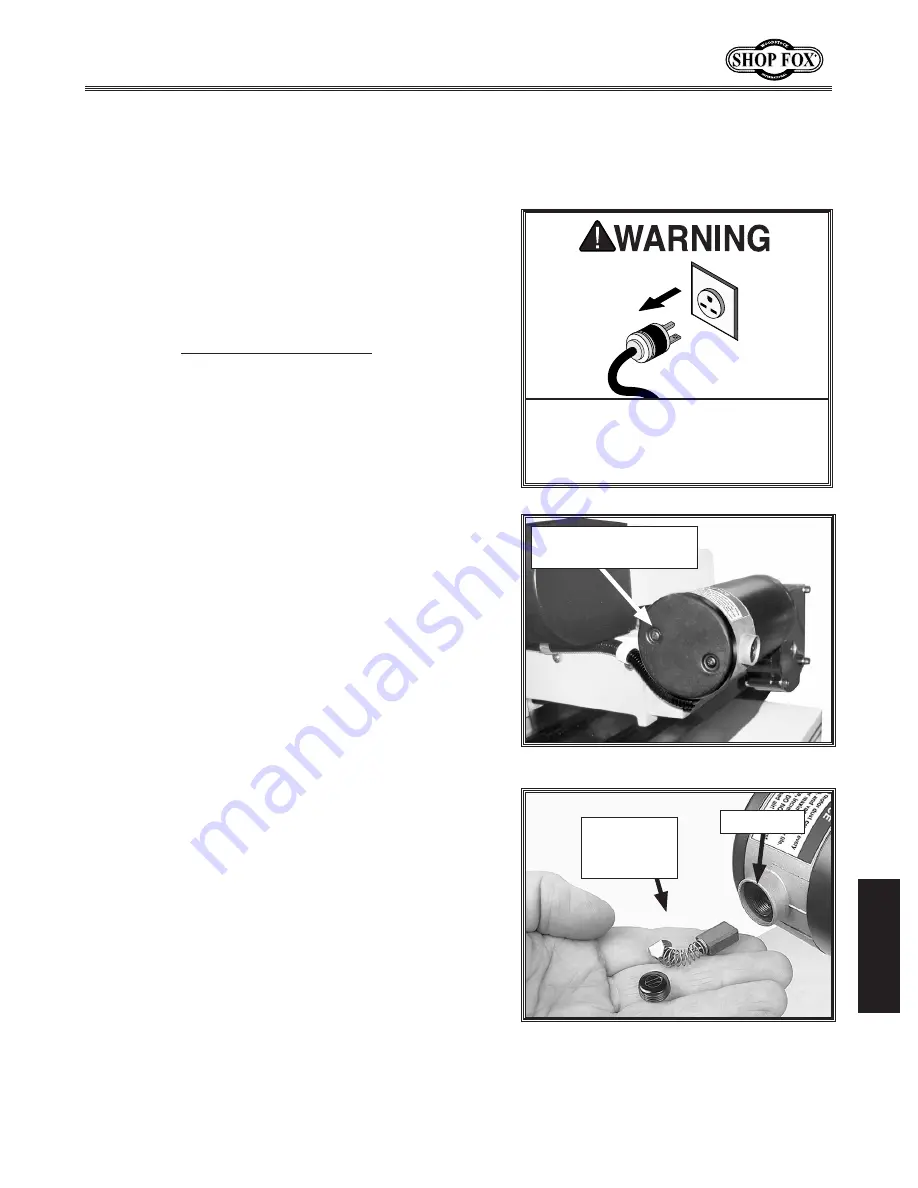

Unscrew the both motor dust cover retaining screws

and remove the dust cover

Figure

52

.

3.

Unscrew the brush covers from both sides of the

motor, and remove the brushes, shown in

Figure

53

.

4.

Vacuum out carbon dust from the motor and both

brush bores. DO NOT blow dust out with compressed

air!

5.

Insert new brushes into the slots in the motor housing,

ensuring that the brush caps are threaded in com-

pletely until they stop.

6.

Screw the brush caps in place.

7.

Reinstall the motor dust cover.

8.

Test run the feed motor.

:_Xe^`e^=\\[Dfkfi

9ilj_\j

D8B< JLI< k_Xk pfli dXZ_`e\ `j

legcl^^\[ [li`e^ Xcc j\im`Z\ gifZ\$

[li\j @] k_`j nXie`e^ `j `^efi\[# j\i`$

fljg\ijfeXc`ealipdXpfZZli

.

Figure 52.

Feed motor end view.

Figure 53.

One of two feed motor

brushes.

Brush Bore

Motor Brush

Cap and

Spring

Motor Dust Cover and

Retaining Screws