Manual 36522G

DPG-2223-00X Controllers

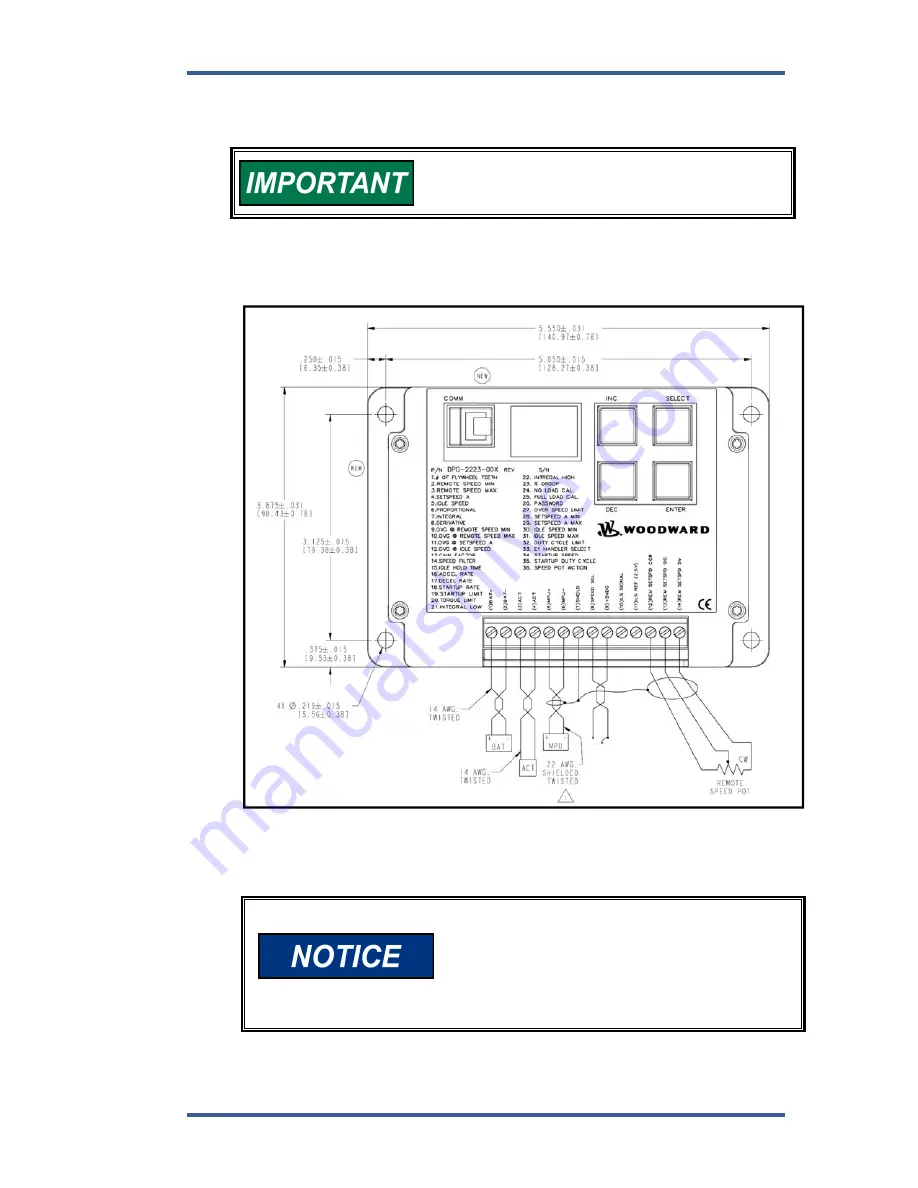

Wiring Diagram

Cabling for DPG 2233-00X controllers is limited to less

than 30m (98.4’). Power cabling is limited to less than

10m (32.8’) in total length. The wiring diagram below

shows specific cable types required.

Dimensions are in inches. [Dimensions in brackets are millimeters.]

Woodward

39

R E M O T E /

S E T S P E E D A

S E L E C T

Figure 1. Wiring Diagram for DPG-2223-00X Models

To prevent damage to the controller, make sure that

it is wired in accordance with the wiring instructions

and diagrams in this manual.

•

Do not tin the leads before placing them into

the terminals.

•

Ensure the terminals are tightened properly

to secure wires.

Summary of Contents for DPG-2223-00 Series

Page 8: ......

Page 57: ...Manual 36522G DPG 2223 00X Controllers Woodward 49...