Manual 26166V1

MicroNet Simplex & MicroNet Plus

Woodward

111

Table 9-3. Module Specification

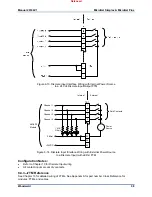

Analog Input Ratings

Number of channels: 24

Update time: 5 ms

Input range: 0-25 mA or 0-5 V; software and hardware selectable

Isolation:

500 Vrms galvanic isolation to earth ground and control

common, no galvanic isolation between channels

60 dB CMRR

200 Vdc common mode rejection voltage

Input imp. (4-20 mA): 200 ohms

Anti-aliasing filter:

2 poles at 10 ms (CH01-22)

2 poles at 5ms (CH23-24)

Resolution: 16

bits

Accuracy: Software calibrated to 0.1%, over 0-25 mA full scale

Temp drift: 275 ppm/C, maximum

Fuse: 100 mA fuse per channel located at FTM

Time stamping: 5 ms resolution on low event and latch, and high event and latch

Table 9-2. 4–20 mA Output Ratings

Number of channels: 8

Update time: 5 ms

Output Driver: linear

Filter: 1 pole at 1ms plus 1pole at 0.25ms

Current output: 4–20 mA

Current output range: 0-25 mA

Isolation: 500 Vrms galvanic isolation to earth ground and control

common, no galvanic isolation between channels

Max load resistance: 600 ohms (load + wire resistance)

Resolution: 14

bits

Accuracy: Software calibrated to 0.2% of 0-25 mA full scale

Temperature drift: 125 ppm/C, maximum

Source read back isolation: 60 dB CMRR, 200 Vdc common mode voltage rejection

Read back Resolution

Source: 12

bits

Return: 8

bits

Read back Accuracy

Source: 0.5% of 0-25 mA full scale

Return: 1% of 0-25 mA full scale

Read back temp drift: 400 ppm/C, maximum

Note:

Item 5466-5025 (pending release in Q2 2016) must be used with Coder Version 5.08 or later.

Coder 4.06 compatible versions:

Item 5466-5026

is backward compatible with P/N 5466-332

Item 5466-5027

is backward compatible with P/N 5466-425

Note:

Item 5466-5026 may be used in place of the 5466-315 if it is acceptable to have 5mS Anti-aliasing

filter on A/I channels 23/24. (vs 10mS anti-aliasing filter). Please consult application engineering.

Note

: AI and AO readback accuracy may be affected if the control is placed in a high electrical noise

environment.

Released