Manual 26518V2

5009FT Installation/Hardware

Woodward

23

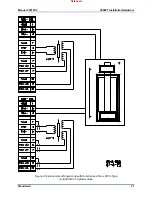

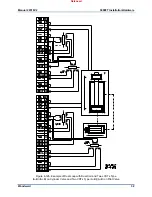

Each FTM connects to the control’s MPU & Analog I/O modules through individual cables, and provides a

common cage-clamp terminal connection for customer field wiring. Figures 4-4 and 4-5 illustrate the

different input wiring configurations based on the type of speed sensing probes used.

Wiring Notes:

Refer to Figures 4-2, 4-3, and

Appendix A

for Speed Sensor wiring connections on the FTMs.

Each Speed input channel can only accept one MPU or one Proximity probe at a time.

If only 2 inputs are available they can be configured and connected as channel 1 and channel 3 (skip

#2) which will place inputs on different FTM modules.

MPUs only (ch1-3)—Jumper must be added to each channel as shown in Figure 4-4 to allow the “C”

analog module to sense speed.

MPUs only (ch1-3)—Jumper must be installed from ‘PROXRTN’ to ‘COM PROX’ as shown in Figure

4-4 to avoid noise issues.

Proximity Probes only—Individual 12 Vdc and 24 Vdc sources, with isolation diodes on the power,

common, and output source lines, are provided with each speed input to power system proximity

probes (100 mA fuses are used on the 24 V output, the 12 V is current limited to 100 mA and located

on the FTMs).

Proximity Probes only—External pull-up resistors are required when interfacing with an open

collector type of proximity probe.

Proximity Probes only—Jumpers must be installed from ‘A&B IN’ and to ‘C IN’ as shown in Figure 4-

5 to avoid noise issues.

Proximity Probes only—If using external power for these inputs, the power supply should be isolated

and must be located within 30 m of the MTMR chassis.

It is required that twisted shielded wiring be used between each probe and FTM.

Shields should be connected together at all intermediate terminal blocks and terminated to earth

ground at the FTM terminal block through the Grounding Bar. The exposed wire length, beyond the

shield, should be limited to 25 mm (1”).

FTM terminals accept wires from 0.08–2.5 mm² (27–12 AWG).

The installation of jumpers on the unused terminals listed in the

above wiring notes are extremely important to ensure that the control

receives good clean speed frequency inputs.

If the speed signals are not within the following limits, the 5009FT

control will respond with a speed sensor frequency error during the

program checking procedure.

(TxMxR)/60 must be < 25 000 Hz

T = Gear Teeth

M = (Overspeed Test Limit Setting x 1.02)

R = Gear Ratio

If the MPU device is not providing a voltage greater than 1.5 Vrms,

the MPU device should be moved closer to the gear where speed is

being monitored. The following graph shows the minimum voltage

necessary to detect speed at the various frequencies.

Released

Summary of Contents for MicroNet TMR 5009FT

Page 65: ...Manual 26518V2 5009FT Installation Hardware Woodward 63 Figure 8 4 DSLC Control Released...

Page 67: ...Manual 26518V2 5009FT Installation Hardware Woodward 65 Figure 8 5 Real Power Sensor Released...

Page 70: ...Manual 26518V2 5009FT Installation Hardware Woodward 68 Released...

Page 71: ...Manual 26518V2 5009FT Installation Hardware Woodward 69 Released...

Page 72: ...Manual 26518V2 5009FT Installation Hardware Woodward 70 Released...

Page 73: ...Manual 26518V2 5009FT Installation Hardware Woodward 71 Released...

Page 74: ...Manual 26518V2 5009FT Installation Hardware Woodward 72 Released...

Page 75: ...Manual 26518V2 5009FT Installation Hardware Woodward 73 Released...

Page 76: ...Manual 26518V2 5009FT Installation Hardware Woodward 74 Released...

Page 77: ...Manual 26518V2 5009FT Installation Hardware Woodward 75 Released...

Page 78: ...Manual 26518V2 5009FT Installation Hardware Woodward 76 Released...

Page 79: ...Manual 26518V2 5009FT Installation Hardware Woodward 77 Released...

Page 80: ...Manual 26518V2 5009FT Installation Hardware Woodward 78 Released...

Page 81: ...Manual 26518V2 5009FT Installation Hardware Woodward 79 Released...

Page 82: ...Manual 26518V2 5009FT Installation Hardware Woodward 80 Released...

Page 83: ...Manual 26518V2 5009FT Installation Hardware Woodward 81 Released...

Page 84: ...Manual 26518V2 5009FT Installation Hardware Woodward 82 Released...

Page 85: ...Manual 26518V2 5009FT Installation Hardware Woodward 83 Released...

Page 86: ...Manual 26518V2 5009FT Installation Hardware Woodward 84 Released...

Page 87: ...Manual 26518V2 5009FT Installation Hardware Woodward 85 Released...

Page 88: ...Manual 26518V2 5009FT Installation Hardware Woodward 86 Released...

Page 90: ...Manual 26518V2 5009FT Installation Hardware Woodward 88 Released...

Page 91: ...Manual 26518V2 5009FT Installation Hardware Woodward 89 Released...

Page 92: ...Manual 26518V2 5009FT Installation Hardware Woodward 90 Released...

Page 94: ...Manual 26518V2 5009FT Installation Hardware Woodward 92 Declarations Released...