Manual 26518V2

5009FT Installation/Hardware

Woodward

28

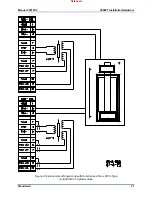

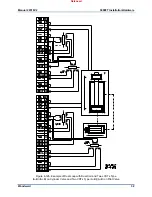

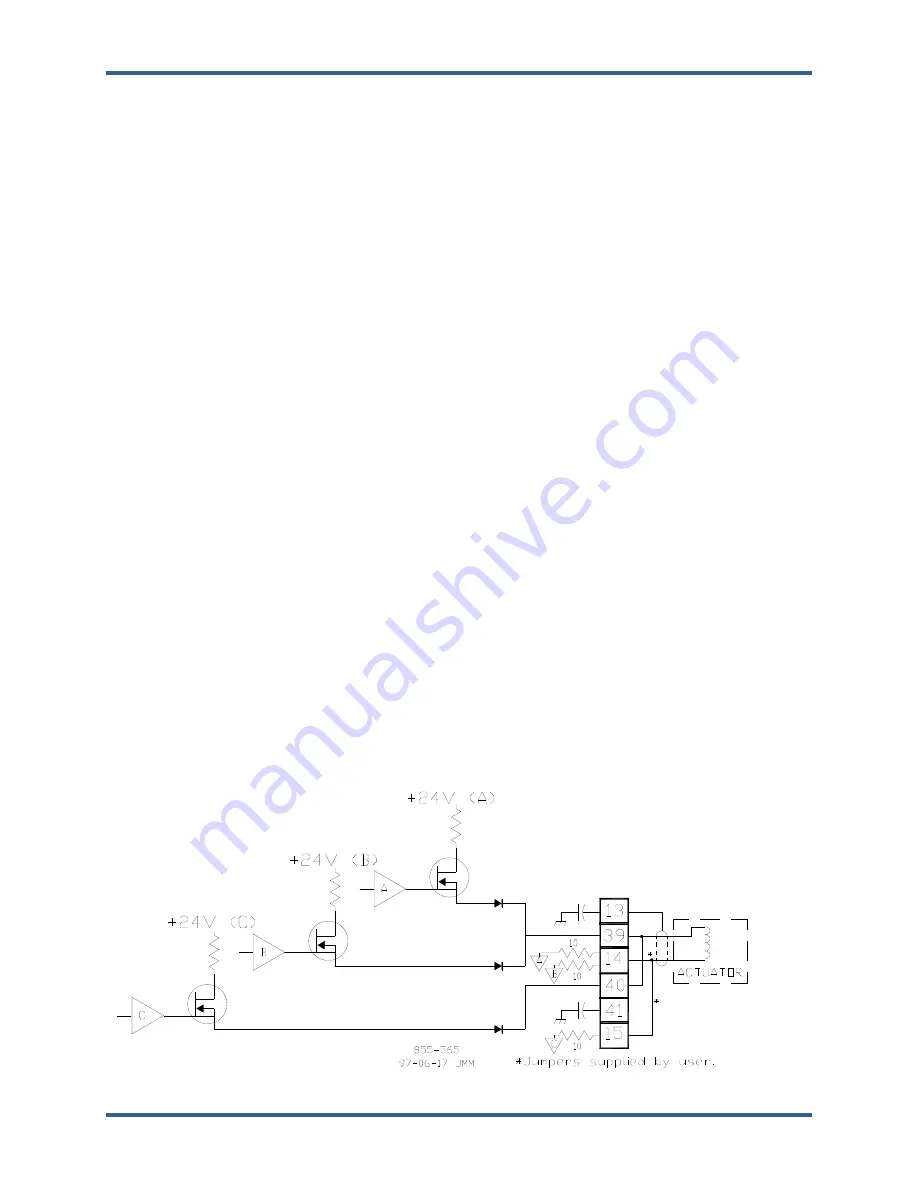

Actuator Outputs—TMR Analog Combo Module

The control has two proportional actuator output drivers (one output per FTM). The actuator output drive

currents can be programmed to interface with Woodward Governor Company actuators (typically 20–160 mA

drive currents) or non-Woodward actuators (4–20 mA drive currents). Each actuator output can be individually

configured to interface with Woodward or non-Woodward type actuators.

Each actuator output can also be configured to drive single- or dual-coil actuators. When configuring an

output to drive into either type of actuator, the output must be wired correctly (see Figures 4-8 and 4-9),

and the control’s program configured for the correct type of actuator. See Volume 3 for details on

programming actuator outputs.

Dither is selectable through the system’s engineering workstation, and is available for either output. Dither

is a low frequency (25 Hz) signal consisting of a 5 millisecond pulse modulated onto the control’s DC

actuator-drive current to reduce stiction in linear type actuators. Woodward TM-type actuators typically

require dither. See Volume 3 of this manual for details on adjusting dither.

Wiring Notes:

Refer to Figures 4-8 and 4-9 and

Appendix A

for Actuator Output wiring connections to the FTMs.

When configured to drive a single coil actuator, user-supplied jumpers are required between

terminals 14 & 15 and terminals 44 & 45.

Maximum impedance for a 4 to 20 mA actuator output driver is 360

Ω

(actuator imp wire

resistance).

Maximum impedance for a 20 to 160 mA actuator output is 45

Ω

(actuator imp wire

resistance).

Each actuator driver senses its drive current to allow over- and under- current alarms and

shutdowns. Refer to Volume 1 of this manual for details on defaulted values and changing them.

It is recommended that 0.75 mm² (20 AWG) or larger twisted/shielded wire be used between each

actuator and FTM.

Shields should be connected together at all intermediate terminal blocks and terminated to earth

ground at the FTM terminal block through the Grounding Bar. The exposed wire length, beyond the

shield, should be limited to

25 mm (1”).

Do not place shielded wires in the same cable conduit with high-voltage or large-current-carrying

cables.

Cable shields must be electrically continuous from the signal source to the point the signal wire

enters the 5009FT Analog Terminal Module.

FTM terminals accept wires from 0.08–2.5 mm² (27–12 AWG) wire.

Actuator outputs are not isolated, so they should not be connected to non-isolated devices.

Figure 4-11. Example Single Coil Actuator Wiring Diagram

Released

Summary of Contents for MicroNet TMR 5009FT

Page 65: ...Manual 26518V2 5009FT Installation Hardware Woodward 63 Figure 8 4 DSLC Control Released...

Page 67: ...Manual 26518V2 5009FT Installation Hardware Woodward 65 Figure 8 5 Real Power Sensor Released...

Page 70: ...Manual 26518V2 5009FT Installation Hardware Woodward 68 Released...

Page 71: ...Manual 26518V2 5009FT Installation Hardware Woodward 69 Released...

Page 72: ...Manual 26518V2 5009FT Installation Hardware Woodward 70 Released...

Page 73: ...Manual 26518V2 5009FT Installation Hardware Woodward 71 Released...

Page 74: ...Manual 26518V2 5009FT Installation Hardware Woodward 72 Released...

Page 75: ...Manual 26518V2 5009FT Installation Hardware Woodward 73 Released...

Page 76: ...Manual 26518V2 5009FT Installation Hardware Woodward 74 Released...

Page 77: ...Manual 26518V2 5009FT Installation Hardware Woodward 75 Released...

Page 78: ...Manual 26518V2 5009FT Installation Hardware Woodward 76 Released...

Page 79: ...Manual 26518V2 5009FT Installation Hardware Woodward 77 Released...

Page 80: ...Manual 26518V2 5009FT Installation Hardware Woodward 78 Released...

Page 81: ...Manual 26518V2 5009FT Installation Hardware Woodward 79 Released...

Page 82: ...Manual 26518V2 5009FT Installation Hardware Woodward 80 Released...

Page 83: ...Manual 26518V2 5009FT Installation Hardware Woodward 81 Released...

Page 84: ...Manual 26518V2 5009FT Installation Hardware Woodward 82 Released...

Page 85: ...Manual 26518V2 5009FT Installation Hardware Woodward 83 Released...

Page 86: ...Manual 26518V2 5009FT Installation Hardware Woodward 84 Released...

Page 87: ...Manual 26518V2 5009FT Installation Hardware Woodward 85 Released...

Page 88: ...Manual 26518V2 5009FT Installation Hardware Woodward 86 Released...

Page 90: ...Manual 26518V2 5009FT Installation Hardware Woodward 88 Released...

Page 91: ...Manual 26518V2 5009FT Installation Hardware Woodward 89 Released...

Page 92: ...Manual 26518V2 5009FT Installation Hardware Woodward 90 Released...

Page 94: ...Manual 26518V2 5009FT Installation Hardware Woodward 92 Declarations Released...