Manual 26518V2

5009FT Installation/Hardware

Woodward

34

If an external power source is used for contact wetting, the external source’s common must be

connected to the FTM’s discrete input commons (terminals 34 & 35). To meet CE or CSA ratings,

power for sensors and contacts must be supplied either by the 5009FT power supplies, or the

external power supply outputs must be rated for 30 Vdc or less and have its outputs fused with

appropriate sized fuses (a maximum current rating of 100/V, where V is the supply’s rated voltage or

5 A, whichever is less).

Each contact input pulls 13 mA @ 24 Vdc (13 mA @ 120 Vdc) when closed, and requires at least 4

mA @ 14 Vdc (4 mA @ 70 Vdc) to recognize a closure command.

Verify that the correct input terminals are wired to with respect to the level of contact wetting voltage

used.

The combined current draw through terminals 27, 28, 29, 30, 31, and 32 cannot exceed 400 mA or

the Discrete I/O module’s on-board power converter will current limit.

It is recommended that 0.75 mm² (20 AWG) or larger wire be used between each discrete input and

the FTM.

FTM terminals accept wires from 0.08–2.5 mm² (27–12 AWG) wire.

If 125 Vdc Contact Power is used, the Power Supply must meet IEC 6164-1, Overvoltage Category

II.

With the use of 125 Vdc contact power, it is recommended that the contact power be removed before

connecting or disconnecting any 5009-to-FTM cable.

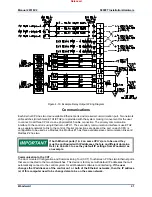

FTM Relay Outputs (F/T Relay Outputs)

There are twelve relay outputs available from the 5009FT control, with three outputs per FTM. With the

exception of Relay #1 – all of the relays are user-configurable. The defaulted outputs are:

Shutdown relay #1 (fixed)

Alarm

relay

Shutdown relay #2

The relay outputs can be programmed to energize upon a function change of state or an analog value

level. Applications requiring programmable relay outputs must have the desired switch condition or

specific analog value assigned to them within the control’s program. Refer to Volume 3 of this manual for

a complete list of programmable relay output options.

The 5009FT control system does not have the capability to provide circuit power to external circuits

interfacing with a relay output. All external circuits interfacing with control relay outputs must have circuit

power provided externally. All relays are dust-tight, magnetic blow-out type relays with Form-C type

contacts.

Refer to MicroNet TMR manual

26167

for all relay ratings.

Latent Fault Detection

Because a fault tolerant system can tolerate a single fault, it is possible for this fault to go undetected.

This is called a latent fault. If another fault occurs when a latent fault exists, it could cause a shutdown.

This is why it is important to detect latent faults in a fault tolerant system.

Each relay output can be individually configured to use latent fault detection to identify relay failures

without affecting a relay output’s state. A fault tolerant relay configuration consists of 6 relays, driven by

two discrete outputs from each kernel. The relays are configured in three legs of two relays each. See

Figure

4-13. Customer circuit power is connected to one side of the resulting configuration, and customer load to

the other side. Field selectable jumpers, located on system FTMs, are provided to allow each output’s

latent fault detection logic to be compatible with the circuit being interfaced to.

Six individual relays make up one relay output. When a relay output is closed, the contacts of all six relays

are closed. Because of the series-parallel configuration that the relays are in, the failure of any two individual

relays will not cause the output to be open. The relay output would continue to be closed. Once a relay

output is closed, the output’s individual relays are periodically opened and re-closed, to ensure that they

were in the correct state, and that they change state.

Released

Summary of Contents for MicroNet TMR 5009FT

Page 65: ...Manual 26518V2 5009FT Installation Hardware Woodward 63 Figure 8 4 DSLC Control Released...

Page 67: ...Manual 26518V2 5009FT Installation Hardware Woodward 65 Figure 8 5 Real Power Sensor Released...

Page 70: ...Manual 26518V2 5009FT Installation Hardware Woodward 68 Released...

Page 71: ...Manual 26518V2 5009FT Installation Hardware Woodward 69 Released...

Page 72: ...Manual 26518V2 5009FT Installation Hardware Woodward 70 Released...

Page 73: ...Manual 26518V2 5009FT Installation Hardware Woodward 71 Released...

Page 74: ...Manual 26518V2 5009FT Installation Hardware Woodward 72 Released...

Page 75: ...Manual 26518V2 5009FT Installation Hardware Woodward 73 Released...

Page 76: ...Manual 26518V2 5009FT Installation Hardware Woodward 74 Released...

Page 77: ...Manual 26518V2 5009FT Installation Hardware Woodward 75 Released...

Page 78: ...Manual 26518V2 5009FT Installation Hardware Woodward 76 Released...

Page 79: ...Manual 26518V2 5009FT Installation Hardware Woodward 77 Released...

Page 80: ...Manual 26518V2 5009FT Installation Hardware Woodward 78 Released...

Page 81: ...Manual 26518V2 5009FT Installation Hardware Woodward 79 Released...

Page 82: ...Manual 26518V2 5009FT Installation Hardware Woodward 80 Released...

Page 83: ...Manual 26518V2 5009FT Installation Hardware Woodward 81 Released...

Page 84: ...Manual 26518V2 5009FT Installation Hardware Woodward 82 Released...

Page 85: ...Manual 26518V2 5009FT Installation Hardware Woodward 83 Released...

Page 86: ...Manual 26518V2 5009FT Installation Hardware Woodward 84 Released...

Page 87: ...Manual 26518V2 5009FT Installation Hardware Woodward 85 Released...

Page 88: ...Manual 26518V2 5009FT Installation Hardware Woodward 86 Released...

Page 90: ...Manual 26518V2 5009FT Installation Hardware Woodward 88 Released...

Page 91: ...Manual 26518V2 5009FT Installation Hardware Woodward 89 Released...

Page 92: ...Manual 26518V2 5009FT Installation Hardware Woodward 90 Released...

Page 94: ...Manual 26518V2 5009FT Installation Hardware Woodward 92 Declarations Released...