Manual 04176

ProAct II Actuator/Driver

Woodward

13

Electrical Connections

External wiring connections and shielding requirements for a typical control

installation are shown in the plant wiring diagram (Figure 1-4).

The type and gauge of the wiring used should follow the wire length and type

shown in the System Wiring section of Chapter 5.

Shielded Wiring

All shielded cable must be twisted conductor pairs or triples. Do not attempt to tin

the braided shield. All signal lines should be shielded to prevent picking up stray

signals from adjacent equipment. Connect the shields to the correct pins on the

driver connector or wiring. Do not connect shields to the actuator ground. Wire

exposed beyond the shield should be as short as possible, not exceeding 50 mm

(2 inches). The other end of the shields must be left open and insulated from any

other conductor. DO NOT run shielded signal wires along with other wires

carrying large currents. See Woodward application note 50532,

Interference

Control in Electronic Governing Systems

, for more information.

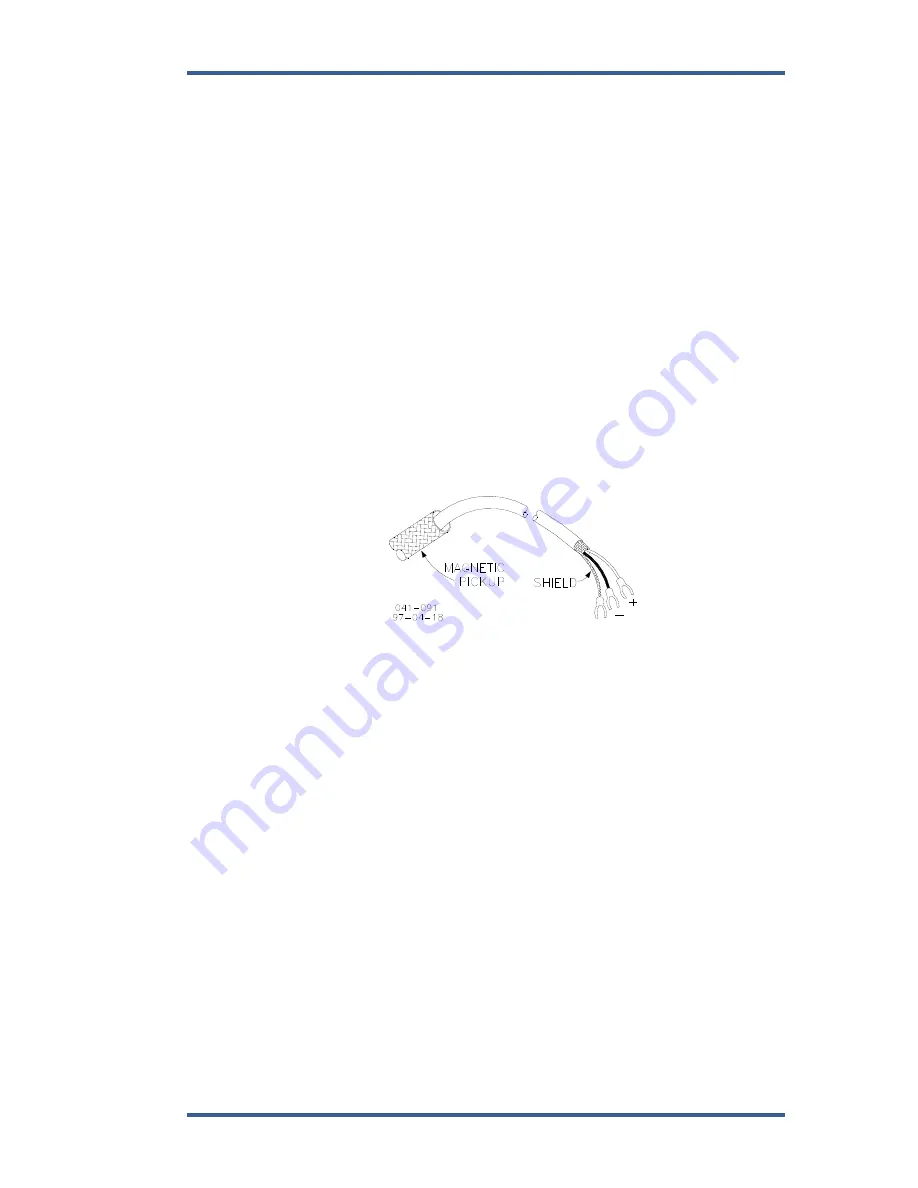

Where shielded cable is required, cut the cable to the desired length and prepare

the cable as instructed below (Figure 2-4).

Figure 2-4. Preparing Shielded Wiring

1.

Strip outer insulation from BOTH ENDS, exposing the braided or spiral

wrapped shield. DO NOT CUT THE SHIELD.

2.

Using a sharp, pointed tool, carefully spread the strands of the shield.

3.

Pull inner conductor(s) out of the shield. If the shield is the braided type,

twist it to prevent fraying.

4.

Remove 6 mm (1/4 inch) of insulation from the inner conductors.

The shield must be considered as a separate circuit when wiring the system. The

shield must be carried through connectors without interruption.

Installations with severe electromagnetic interference (EMI) may require

additional shielding precautions. Contact Woodward Governor Company for

more information.

Failure to provide shielding can produce future conditions which are difficult to

diagnose. Proper shielding at the time of installation is required to assure

satisfactory operation of the ProAct control system.