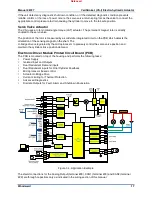

Manual 26727

VariStroke-I (VS-I) Electro-hydraulic Actuator

Woodward

11

EXPLOSION HAZARD—Do not remove covers or connect/disconnect

electrical circuits unless power has been switched off or the area is

known to be non-hazardous.

Substitution of components may impair suitability for Class I, Division

2 or Zone 2 applications.

Risque d'explosion -- Ne pas enlever les couvercles, ni

raccorder / débrancher les prises électriques, sans vous en

assurez auparavant que le système a bien été mis hors

tension; ou que vous situez bien dans une zone non

explosive.

La substitution de composants peut rendre ce matériel

inacceptable pour les emplacements de Classe I, applications

Division 2 ou Zone 2.

Safety Symbols

Direct Current

Alternating Current

Both Alternating and Direct Current

Caution, risk of electrical shock

Caution, refer to accompanying documents

Protective conductor terminal

Frame or chassis terminal

Released