1.1 Gas Safety (Installation & Use) Regulations 1998:

The appliance is suitable for installation in GB/IE only and

should be installed in accordance with the rules in force.

It is the law in GB that a competent person in accordance with

the above regulations installs all gas appliances.

Failure to install appliances correctly could lead to prosecution.

It is in your interest, and that of safety, to ensure compliance

with the law.

1.2

The manufacturers notes must not be taken, in any way, as

overriding statutory obligations.

1.3

The compliance with a British Standard or European Norm

does not, in itself, confer immunity from legal obligations.

1.4.1

The installation of the appliance must be in accordance

with the relevant requirements of the Gas Safety Regulations,

current IEE Regulations, Building Regulations, Building Standards

(Scotland) and local water by-laws.

1.4.2

In Eire the installation must be carried out by a competent

person and installed in accordance with IS 813, Domestic Gas

Installations (Edition 2), the current building regulations and the

electrical installation must follow the ETCI rules.

1.5

The installation should follow the recommendations of the

following British Standards unless otherwise indicated.

BS5440:1 - Flues and ventilation for gas appliances: Flues

BS5440:2 - Flues and ventilation for gas appliances: Air supply.

BS5449 - Central heating for domestic premises.

BS5482 - Domestic propane gas burning installations.

BS5546:1 - Installation of gas hot water supplies.

BS6700 - Domestic water supply in buildings.

BS6798 - Installation of gas fired hot water boilers.

BS6891- Low pressure gas pipework installations upto 28mm (R1).

BS7593 - Water treatment.

BS7671 - Requirements for electrical installations.

1.6

The appliance does not contain any substances which are

harmful to health.

1.7

In certain circumstances, the installer can be held

responsible, not only for mistakes on his part but also for

damage resulting from the use of faulty materials. We advise

that, to avoid any risk, only quality approved branded fittings

are used.

1.8 LPG Installation:

The appliance shall not be installed in a room or internal space

below ground level when it is intended for use with LPG. This

does not preclude the installation into rooms, which are

basements with respect to one side of the building but open to

the ground on the opposite side.

1.9

These instructions cover, as far as possible, the foreseeable

situations, which may arise.

Contact Worcester Heat Systems Technical Department,

Telephone: 08705 266241, for advice on specific installations.

2.1

The

initiative is the new code of practice to encourage

the correct installation, commissioning and servicing of domestic

central heating boilers and system equipment.

The 'Log-book' is a vital document that must be completed

by the installer at the time of installation. It confirms that the

boiler has been installed and commissioned according to the

manufacturers instructions.

A declaration of conformity (Refer to IS 813 Annex D1) must be

completed by the installer and a copy supplied to the appliance

operator for boilers installed in Eire.

Without the completion of the Log-book and/or declaration,

manufacturers may refuse to respond to a call-out from a

householder, who will be advised that he or she must call back the

installer, who has not fulfilled his obligations to record the

information required by the initiative.

Service:

To ensure continued efficient operation of the appliance it must be

checked at regular intervals. The frequency of servicing will depend

upon the particular installation conditions and usage, but once per

year should generally be adequate. The extent of the service

required by the appliance is determined by the operating condition

of the appliance when tested by fully qualified engineers.

Any service work must be carried out by competent registered

engineers (CORGI in GB).

2.2 General Information

The appliance is set to give the maximum output of 28 kW [28Si II] or

24kW [24Si II] to the domestic hot water and to the heating system.

The hot water flow rate is limited to a nominal 10 l/min [28Si II] or 8

l/min [24Si II] at a maximum temperature rise of 40°C.

The sanitary water section of the appliance is suitable for mains

water pressure of upto 10bar.

Kits are available to convert the appliance from Natural Gas to

Propane operation and vice versa.

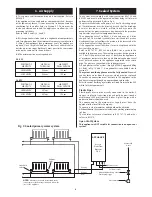

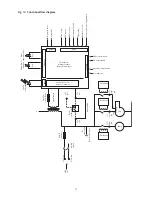

2.3 Electrical Supply

230V - 50Hz. Load 180 watts. External fuse 3A (to BS1362),

Internal fuses F1 - 2A, F2 - 1.25A (20mm).

2.4 Gas Supply

The appliances require a maximum of 3.25 m

3

/h of natural gas

(G20) or 1.25 m

3

/h of propane (G31) [28Si II] or 2.8 m

3

/h of

natural gas (G20) or 1.08 m

3

/h of propane (G31) [24Si II].

The installation and the connection of the gas supply to the

appliance must be in accordance with BS6891.

The meter or regulator should deliver a dynamic pressure of 20 mbar

(G20) or 37mbar (G31) at the appliance, which is equivalent to about

19 mbar or 36 mbar at the gas valve inlet pressure test point.

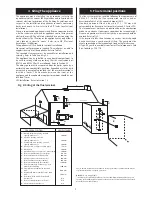

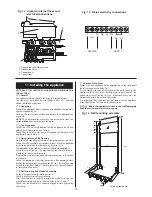

2.5 Installation

The appliance is suitable for indoor installation only and for use

with a sealed system only.

Do not place anything on top of the appliance.

This is a room sealed appliance and a separate combustion air

supply is not required in any room or compartment in which the

appliance is fitted.

If the appliance is fitted in a cupboard or a compartment is built

around it after installation, then the structure must conform to the

requirements of BS6798 and BS5440 Part 2. However, because of the

low casing losses, there is no need for cooling ventilation openings in

2. Introduction

1. Installation Regulations

2

1. Installation Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

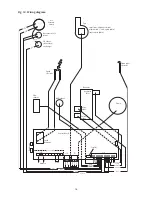

10. Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

2. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

11. Installing the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

3. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

12. Commissioning the Appliance . . . . . . . . . . . . . . . . . . . . Page 19

4. Siting the Appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

13. Handover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21

5. Flue Terminal Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

14. Inspection and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21

6. Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

15. Replacement of Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 24

7. Sealed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

16. Short Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 30

Open Vent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

17. Operational Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . Page 32

8. Domestic Hot Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

18. Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 34

9. Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

19. Conversion Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . Page 42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents