IMPORTANT: Turn off the gas supply and electrically isolate

the appliance before replacing any components

.

After the replacement of any components always check for gas

soundness where relevant and carry out functional checks as

described in Section 12-Commissioning.

Any O-ring or gasket that appears damaged must be replaced.

Complete gasket and O-ring packs are available for gas and

water connections on the appliance.

Component Access

Refer to Section 14, Inspection and Servicing for access to

components.

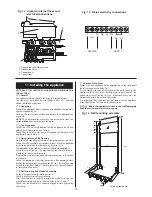

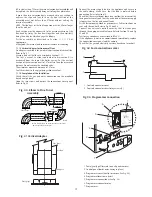

Draining the Appliance

Primary System: Turn off the heating flow and return valves at

the appliance. Refer to Fig 17.

Open the drain tap a short tube is already connected to the drain

point. Refer to Fig. 20. Close the drain tap when the flow from the

appliance has stopped.

DHW Circuit:

Turn off the mains cold water supply at the

appliance. Refer to Fig 16. Open a hot tap below the level of the

appliance to drain the domestic hot water from the appliance.

Important: A small quantity of water will remain in some

components even after the appliance has been drained.

Protect any electrical components when removing items from

the water circuits.

Component Replacement

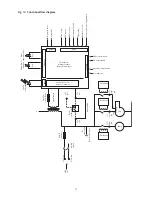

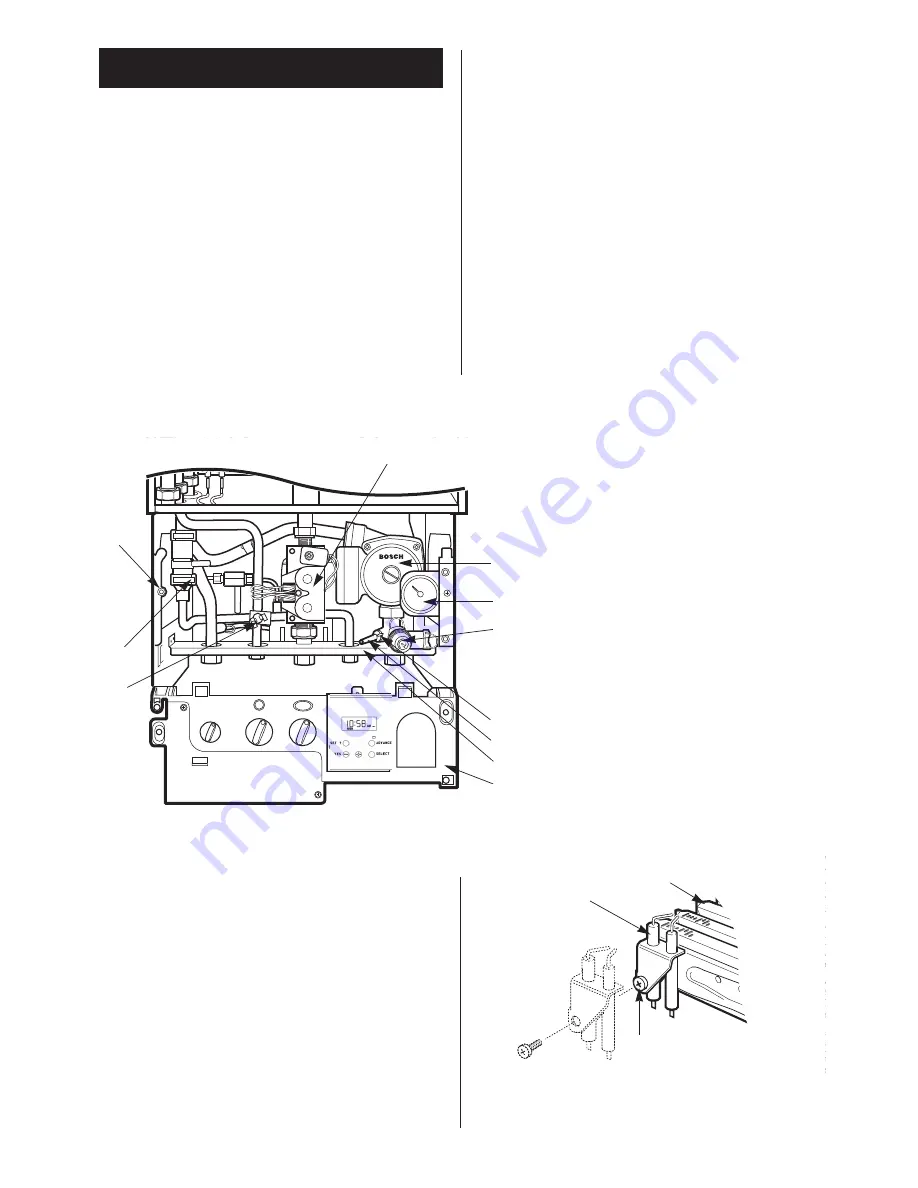

Refer to Fig 42 and 44 for an indication of the location of the

various components.

Replace any components removed from the appliance in the

reverse order using new gaskets/O-rings/sealant/heat transfer

paste where necessary. Always check that any electrical

connections are correctly made and that all screws are tight.

Remove casing and cover panels and lower the facia onto lower

lugs, as necessary, to gain access to the components. Refer to

Section 14, Inspection and Servicing.

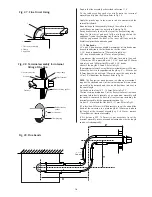

15.1 Gas Valve

Unscrew the union connections above and below the gas valve

and remove the assembly. Disconnect/unplug the electrical

connections from the valve.

Use new gaskets when replacing the valve. Refer to Fig 48.

Set the Gas Valve:

Connect a pressure gauge to the burner and inlet pressure test

points on the valve. Refer to Fig 39.

Switch on the gas and electricity supplies.

Check for gas tightness at the gas valve inlet.

Refer to Section 12.5 Commissioning for the method of

checking/setting the pressures.

Check for gas soundness at the gas valve outlet.

Adjust the maximum and start pressure [minimum], as

necessary, to obtain the required pressures. Switch off the

appliance and disconnect the pressure gauge. and tighten the

screw. Refer to Section 12.5 and Fig 39 for setting instructions.

Check for gas soundness at the test point.

15. Replacement Of Parts

24

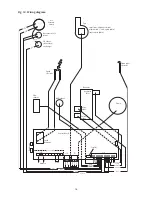

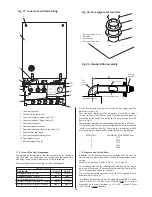

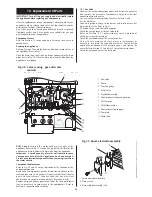

Fig. 48 . Lower casing - gas and water

controls.

1

9

8

7

6

5

4

3

2

1. Gas valve

2. Pump

3. Pressure guage

4. Relief valve

5. Manifold assembly

6. Control panel in lowered position

7. DHW sensor

8. DHW flow turbine

9. Control panel top support

10. Drain tap

11. Drain tube

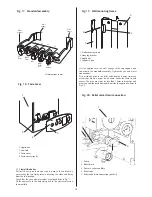

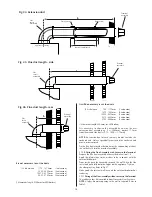

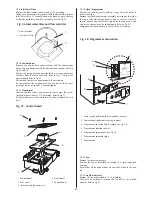

Fig. 49. Spark electrode assembly

1

3

2

1. Spark electrode assembly

2. Fixing screw

3. Burner blade assembly (LH)

11

10