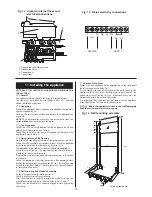

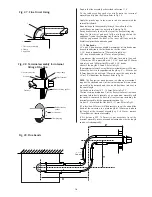

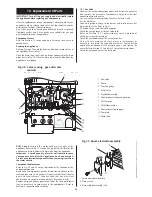

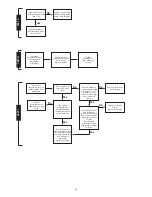

15.5 Combustion Chamber Insulation, Front &Sides

Remove inner casing door and combustion chamber.

Remove damaged insulation, replacement is the reverse of

removal. See Fig 52.

Combustion Chamber Insulation, Rear

Remove heat exchanger as described in 15.21.

Remove side panels first.

Pull insulation forward and up to remove.

Replacement is the reverse of removal. Refer to Fig 52.

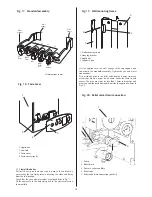

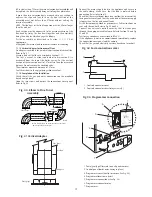

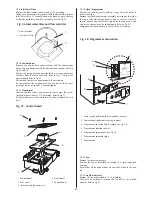

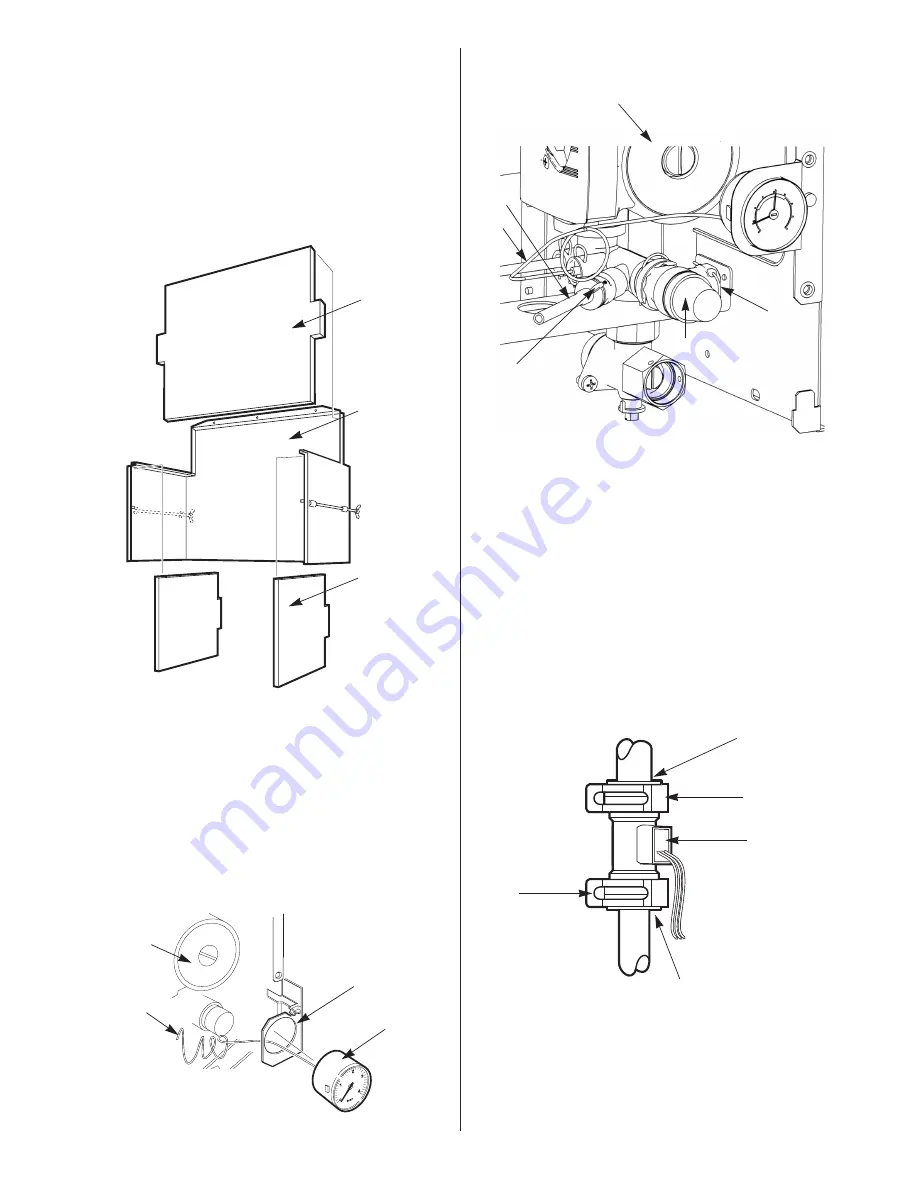

15.6 Pressure Gauge

Remove the clip-on facia cover, cabinet and lower the facia panel

onto the lower support lugs. Refer to Fig 43. Check that the

appliance has been fully drained. Withdraw the clip and remove

the pressure-sensing head. Refer to Fig 53.

Unclip the gauge head from its mounting bracket and remove.

Refer to Fig 53.

Do not omit the washer from the pressure capillary when fitting

the replacement gauge.

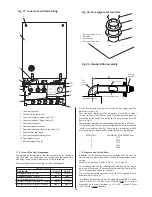

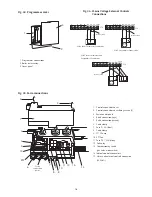

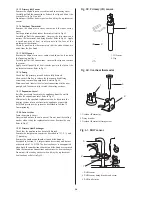

15.7 Relief Valve

Remove the clip-on facia cover, cabinet and lower the facia onto

the lower support lugs.

Check that the appliance has been fully drained.

Unclip and pull-out the valve body. Refer to Fig 54

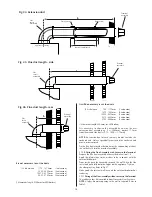

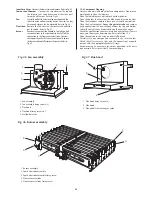

15.8 Flow Turbine

Drain the DHW circuit as described at the start of Section 15

preceding.

Remove the clip on facia cover, cabinet and lower the facia panel

onto the lower support lugs. Separate the in-line connector. Remove

the two fixing clips and withdraw the turbine. Refer to Fig 48 and 55.

Do not omit the gaskets when fitting the replacement turbine.

26

Fig. 53. Pressure Gauge head

Fig. 54. Relief valve boiler drain connection

Fig. 52. Combustion Chamber Insulation

Front and Sides.

2

3

1

1. Insulation panel-side

2. Insulation panel-front 3. Combustion chamber assembly

1

2

4

3

1. Pump

2. Pressure gauge capillary

3. Pressure gauge head

4. Mounting bracket

1

6

2

3

5

1. Pump

2. Boiler drain

3. Pressure gauge capillary

4. Boiler Drain ON/OFF

5. Relief valve

6. Relief valve drain connection (push fit)

Fig. 55. Water flow turbine.

2

2

1

1. Flow turbine

2. Flow turbine clips

3. Inlet

3. Outlet

4

3

4