ONLY COMPONENTS SUPPLIED BY WORCESTER HEAT

SYSTEMS SHOULD BE USED.

ONLY COMPETENT PERSONNEL SHOULD ATTEMPT

THE CONVERSION.

CONVERSION FROM NATURAL GAS TO LPG SHOULD

NOT BE CARRIED OUT ON APPLIANCES INSTALLED IN

A ROOM OR INTERNAL SPACE BELOW GROUND LEVEL

24kW 28kW

Conversion Kit NG to LPG 7 716 192 288 7 716 192 289

1.

Ensure the gas service cock is turned

OFF

and the electrical

supply is

ISOLATED

.

2.

Refer to the Installation and Service Instructions Section14:

Inspection and Servicing to remove the cabinet front panel

and outer casing.

3.

Follow the dismantling instructions to remove the burner.

Refer to Section: 14.3 Inspection and Servicing.

4.

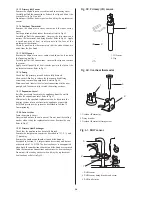

Remove the burner blades as shown in 15.4.

5.

Replace the burner manifold with a new one supplied in the kit.

6.

Refit burner blades taking care to assure that the cross

lighting strip and blades are correctly fitted and aligned.

7.

Remove the gas valve and replace with the gas valve

supplied in the kit. Refer to the Installation and Servicing

Instructions Section 15- Replacement of Parts.

NOTE:

Replace the fibre washer with one of those supplied

in the kit.

8.

Refit the burner assembly to the gas valve using the other

fibre washer supplied in the kit.

9.

Ensure that the sealing grommet around the burner

manifold is correctly sealed to the boiler casing.

9.

Remove plastic anti-tamper seal and plastic cap from the gas

valve.

10.

Turn on the gas and electricity supplies and follow the

commissioning procedure to confirm gas soundness and

correct boiler operation.

11.

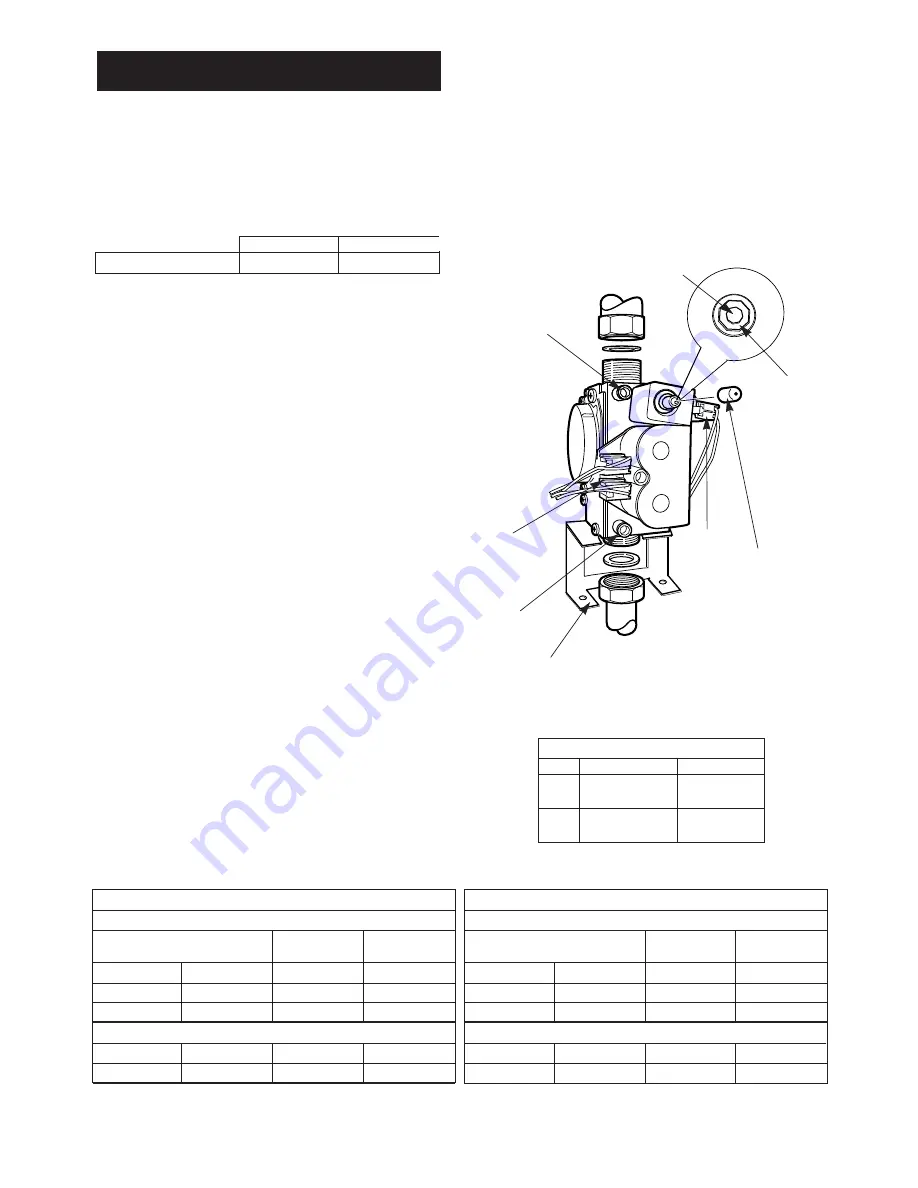

Check and adjust the setting pressures to the values in

Table 1 and adjust if necessary. Refer to the Installation and

Service Instructions Section 12.5 for the setting of the gas

valve and refer to Fig 1.

Ensure that the joints on the gas valve to the burner and

inlet are both checked for gas soundness.

12.

Refit the plastic sealing cap to the gas valve modulating valve

and seal with a dab of paint or similar.

13.

Turn off the boiler and when cool peel off the arrow from the

data plate on the combustion box front panel and re-stick

against the gas type for which the boiler has been converted

and adjusted.

13.

Replace the boiler front panel.

The conversion is now complete.

42

19. Conversion Instructions

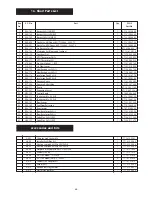

NOMINAL BOILER RATINGS (10 Minutes After Lighting)

BOILER ADJUSTED FOR G20 (Natural Gas)

OUTPUT INPUT (Net)

GAS RATE

kW

kW

m bar.

m

3

/h

8.1

9.2

0.7

0.97

28

30.7

13.1

3.25

BOILER ADJUSTED FOR G31 (Propane)

8.1

9.2

2.8

0.38

28

30.7

34.5

1.25

Table 1.

28Si II

BURNER

PRESSURE

NOMINAL BOILER RATINGS (10 Minutes After Lighting)

BOILER ADJUSTED FOR G20 (Natural Gas)

OUTPUT INPUT (Net)

GAS RATE

kW

kW

m bar.

m

3

/h

6.9

7.9

0.9

0.84

24

26.4

12.1

2..8

BOILER ADJUSTED FOR G31 (Propane)

6.9

7.9

3.1

0.32

24

26.4

35.0

1.08

Table 1.

24Si II

BURNER

PRESSURE

Natural Gas: Net Input = Gross Input x 0.901

LPG (Propane): Net Input = Gross Input x 0.922

NOTE:

With longer flue lengths, not using a restrictor, the minimum burner pressure will rise, naturally due to the flue, to 1.1mbar on G20

appliances only.

Injector sizes and markings

G20 Natural gas G31LPG

24kW 1.07 mm

0.65 mm

(marked 107) (marked 65)

28kW 1.12 mm

0.69 mm

(marked 113) (marked 69)

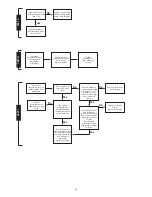

Max

2mm

Allen key

Min

3mm

Allen key

Gas valve

sealing

cap

Burner

pressure

test point

Electrical

connections

modulator

(Blue:Blue)

Minimum /

Maximum

pressure

adjuster -

Allen key*

(see

Note

)

Inlet

pressure

test point

Main gas

valve

connections

*Note:

Clockwise

to increase and

anti-clockwise to

decrease the pressure.

Gas valve bracket

Fig 1. Gas Valve