It may be necessary to contact the local Water Company before

connecting the appliance.

Where back-flow prevention devices,

including water meters, are fitted the expansion of hot water into

cold water main can be prevented. This can result in a pressure

build-up that may cause damage to the boiler and household

devices such as showers, washing machines etc.

In these cases we recommend that a mini-expansion vessel be

fitted adjacent to the boiler in the cold water pipe.

The last 600mm of mains water pipe before the appliance must

be in copper.

The domestic hot water circuit of the appliance is suitable for a

mains pressure of upto 10bar. A pressure reducing valve must be

fitted if necessary.

A mains water supply isolating valve is fitted.

The maximum hot water flow rate is set at the factory to 8 l/min

[24Si II] and 10 l/min [28Si II] giving a nominal temperature rise

of 40

o

C with the temperature control at maximum. This rate is

equivalent to a Specific Rate of 11.5 l/min [24Si II] and 12.9

l/min [28Si II] at a rise of 30

o

C. Refer to Table 6. The temperature

rise, upto the maximum set by the user, is maintained by the

automatic modulation of the heat input.

In winter, when the water temperature is lower it may be

necessary to reduce the water flow at the tap or shower to

maintain the maximum delivery temperature.

It is recommended that long pipe runs to taps or showers are

insulated to prevent the rapid cooling of the water.

Hot and cold taps and mixing valves must be suitable for the

available mains pressure.

No anti-syphonage arrangements are necessary for fixed head

showers. The hose of a loose-head shower must be fixed so that

the shower head cannot get closer than 25mm to the top edge of

the bath to prevent its immersion in the water. Alternatively the

shower can be fitted with an anti-syphonage device at the flexible

hose connection. Thermostatically controlled or pressure

balancing shower valves will give extra comfort and guard

against extreme temperature.

Hot and cold mains water direct to a bidet is, subject to the

approval of the local water company, permissible provided that

the bidet is of the overrim flushing type. The outlets must be

shrouded and unable to be fitted with a hand-held spray. No anti-

syphon arrangements are needed.

LIME SCALE: In areas of temporary hardness [>200ppm of calcium

carbonate] it is suggested that a proprietary scale reducer is fitted

in the mains cold water connection to the appliance. Installation of

a scale inhibitor assembly must be in accordance with the

requirements of the local Water Company. The water hardness can

be determined by reference to the local Water Company.

An isolating valve should be fitted to allow servicing.

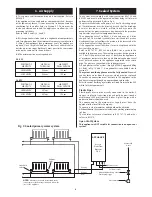

The appliance requires a maximum of 2.8 m

3

/h [24Si II],

3.25m

3

/h [28Si II] of natural gas (G20) or 1.08 m

3

/h [24Si II],

1.25m

3

/h [28Si II] of propane (G31). Refer to Table 7.

A natural gas appliance must be connected to a governed meter.

The installation and connection of the gas supply to the

appliance must be in accordance with BS6891.

The meter (NG) or regulator (LPG) and the pipework to the

appliance must be checked, preferably by the gas supplier, to

ensure that a dynamic pressure of 20mbar for natural gas or

37mbar for propane is available at the appliance (contact gas

supplier if in doubt) equivalent to about 19mbar [NG] or 36mbar

[LPG] respectively at the gas valve inlet pressure connection and

that the gas flow is adequate for all the installed gas appliances

operating together.

Mains supply: 230V ~ 50 Hz 180watts.

External fuse 3A to BS1362. Internal fuses F1-T2A, F2-TI.25A

(20mm). Spare internal fuses are supplied with the appliance.

The mains cable must be 0.75mm

2

(24x0.20 mm) to BS6500 -

Table 16 and must be connected to the terminal ST2 marked L

(red or brown lead), N (black or blue lead) and the Earth stud

(green or green/yellow lead) and secured with the cable clamp.

The Earth lead must still be slack when the other leads are taut.

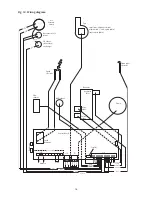

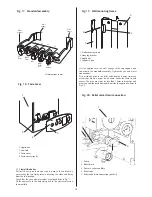

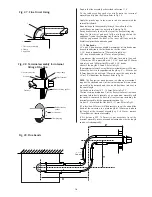

Refer to Fig 14 and 15.

The appliance must be earthed.

The wiring between the appliance and the electrical supply shall

comply with current IEE wiring regulations (and any local regulations

which apply) for fixed wiring to a stationary appliance.

NB

. It must be possible to completely isolate the appliance with at

least 3mm contact separation in both poles.

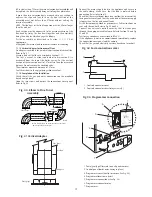

A room thermostat or externally mounted programmer must be

suitable for mains voltage operation. The leads must be securely fixed

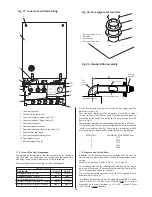

in the cable clamps (see Fig. 35)

A facia mounted digital programmer or mechanical timer or receiver

for wireless programmable room thermostat is available as an

optional extra. Instructions are supplied with the product.

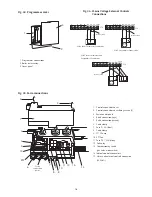

On very rare occasions it may be necessary to fit an external

frost thermostat to protect remote parts of the system. In this

case refer to the WHS Technical Department for information,

Tel: 08705 266241.

10. Electrical

8. Domestic Hot Water

9

9. Gas Supply

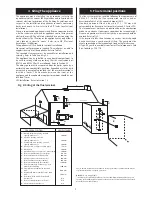

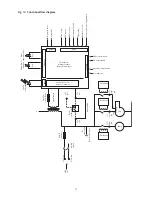

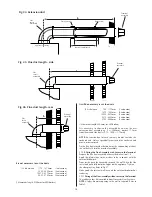

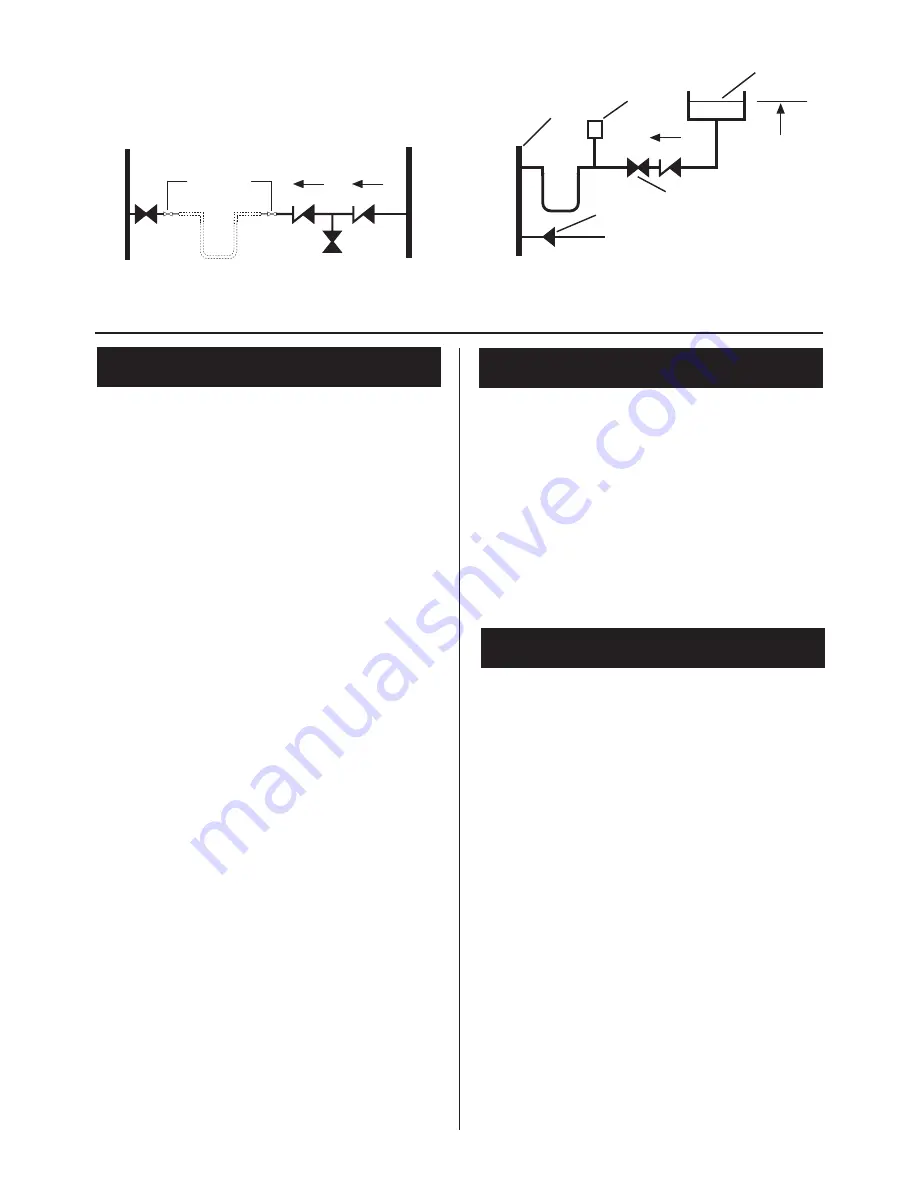

Fig 10 - System Fill

Fig 11 - System make up

1.Central Heating Return

2.Auto Air vent

3.Non-return Valve

4.Make-up Vessel

5.Stop Cock

6.Fill Point

4

1

2

3

5

6

300mm Above

the highest point

of the system

Heating

return

Stop

cock

Hose union

Temporary hose

Non return

valve

Non return

valve

Test cock

Mains water

supply