15.1 SERVICING

To ensure continued efficient operation of the appliance it must

be checked and serviced as necessary at regular intervals. The

frequency of servicing will depend upon the particular

installation conditions and usage, but once per year should

generally be adequate. The extent of the service required by the

appliance is determined by the operating condition of the

appliance when tested by fully qualified engineers.

Any service work must be carried out by competent engineers

such as British Gas or Corgi registered personnel.

15.2 PRE-SERVICE INSPECTION

Check that the flue terminal and the terminal guard, (if fitted), are

clear.

If the appliance is in a compartment, check that the ventilation

openings in the compartment door or walls are clear. See Section

6 - Air Supply.

Check the system and remake any joints or fittings which show

signs of leakage.

Refill, vent and re-pressurise as described in Section 13.2.

Operate the appliance and the system taking note of any faults.

Measurement of the Flue Gases

For consistency of results of the flue gas measurements it is

necessary to have a constant output and for the appliance to be

at equilibrium.

Turn on a tap to create a hot water demand.

Wait until the appliance reaches thermal equilibrium (approx. 10

minutes).

Remove the test point sealing screw on the appliance top panel.

See Fig. 17 and 30.

Connect to the test point with a piece of tubing.

Expected measurements should be between:

For Natural Gas:

7.0 - 7.5%

Carbon Dioxide

0.003 - 0.007%

Carbon Monoxide

After taking the measurement replace the sealing cap.

IMPORTANT

Disconnect the electrical supply at the mains and turn off the

gas supply at the gas service cock on the appliance before

servicing.

After completing the service always test for gas soundness as

indicated in BS 6891.

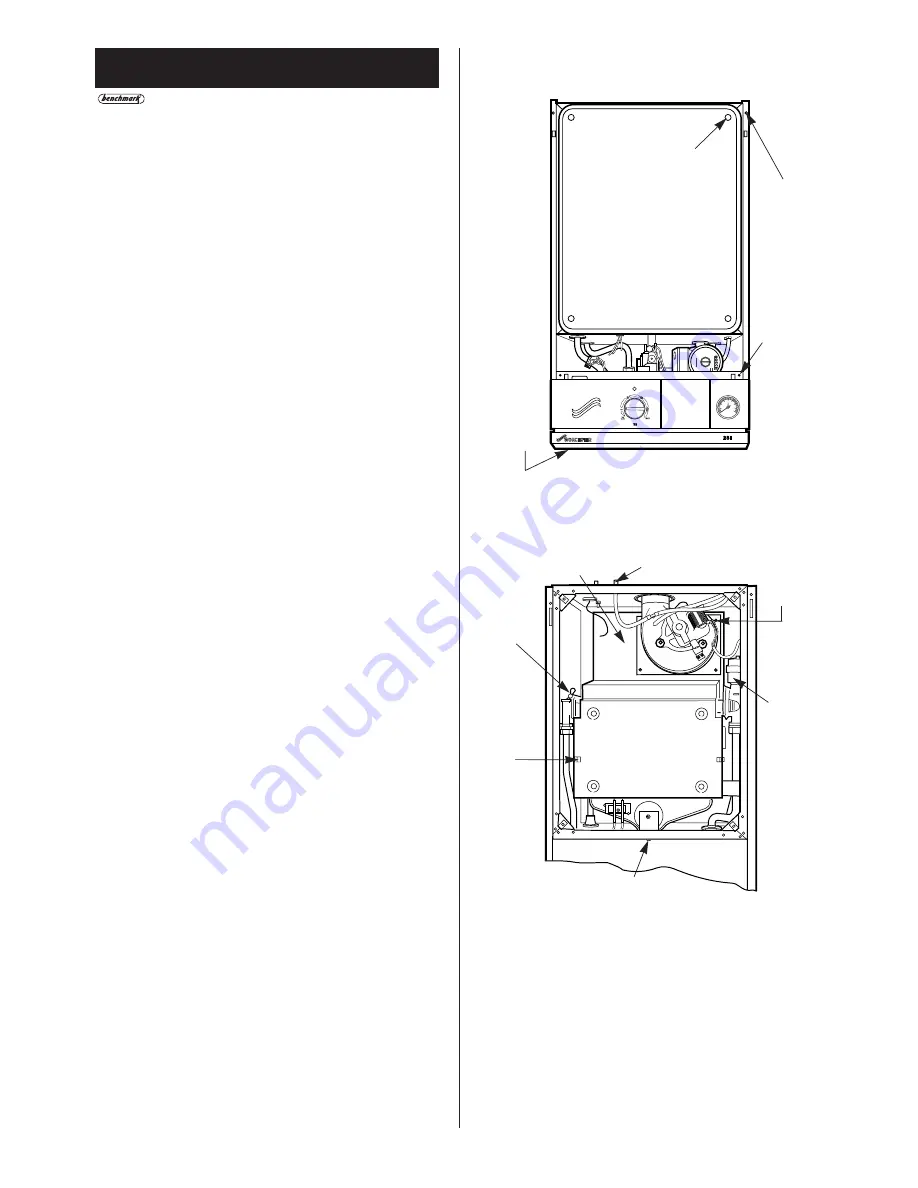

15.3 DISMANTLE THE APPLIANCE

To carry out a full and comprehensive service of the appliance

remove the following parts to gain access to the components

which need to be checked or serviced.

(a) Cabinet Front Panel.

Remove by lifting off the supports.

(b) Inner Casing Cover.

Check that the electricity supply to the

appliance is turned off. Remove the cabinet front panel. Unscrew

the four screws securing the cover to the casing and lift off. See Fig. 35.

(c) Facia Panel.

Check that the electricity supply to the appliance

is turned off. Remove the cabinet front panel. Unscrew the two

upper screws as shown in Fig. 35. and hinge down the facia

taking care not to damage the pressure gauge capillary tube or

electrical connections.

(d) Bottom panel.

Unclip and remove the appliance bottom panel.

(e) Fan.

Remove the inner casing cover as detailed in Section

15.3(b) above. Carefully unplug the electrical connections and

pull off the sensing tubes. Unscrew the four fixing screws and

remove the fan assembly. See Fig. 36.

(f) Combustion Chamber Front.

Remove the inner casing cover.

Undo the spring clips fixing the combustion chamber front

taking care not to damage the insulation on removal. See Fig. 36.

(g) Flue Hood Assembly.

Remove the fan assembly as described

in Section 15.3(e). Remove the combustion chamber front taking

care not to damage the insulation. Lift and slide the flue hood

assembly from the appliance. See Fig. 36. When refitting the hood

ensure that the rear return edge passes under the lip at the rear of the

combustion chamber.

15. Inspection And Service

21

Inner casing

cover

screws (4)

Side casing

fixing

screws (4)

Facia panel

fixing

screws (2)

Bottom

facia panel

fixing

screws (3)

Fig.35. Appliance casing and control

equipment fixings.

Fig. 36. Appliance components and fixings

(upper assembly).

1

7

5

6

4

3

2

1 Flue hood

2 Flue Gas Test Point

3 Fan assembly fixing screws (4)

4 Auto air vent

5 Burner fixing screw

6 Combustion chamber cover fixing clips (2)

7 Overheat thermostat