An optional vertical flue kit to provide for flue lengths up to

3400mm including vertical flue terminal.

A terminal guard, Type K2, GC 393 553, is available from Tower Flue

Components, Vale Rise, Tonbridge, TN9 1TB.

Do not allow the flue terminal fitted to the outside wall to become

obstructed or damaged.

A kit for internal fixing of the flue is available separately.

2.6

Controls

Central Heating Temperature control knob.

A facia mounted programmer is provided.

A room thermostat and/or an externally mounted programmer

for mains voltage operation may be connected to the appliance.

2.7

System

All dirt must be flushed from the system before

operating the appliance.

The connections in the system must withstand a pressure of

upto 3 bar.

Radiator valves must conform to BS2767: 10:1977.

Table 3 gives the pump head available for the system and the

required temperature differential.

A drain cock must be fitted to the lowest point and an air vent to

the highest point of the system.

2.8

Showers, Bidets, Taps and Mixing Valves

All taps and mixing valves must be suitable for the available

mains pressure and temperatures up to 55°C. It may be

necessary to fit a pressure reducing valve.

Hot and cold mains fed water can be supplied to over-rim bidets

but is subject to local water company requirements.

The flow of water from individual outlets varies on all mains fed

systems that are not fitted with flow balancing valves. If a

pressure equalising valve is fitted then the domestic hot water

temperature should be set to maximum.

Thermostatically controlled shower valves give extra comfort

and protection.

2.9

Safety

The appliance must not be operated with the inner casing cover removed.

The gas and electricity supplies must be turned off before

working on the appliance.

Temperature monitoring controls are fitted to prevent overheating.

Automatic frost protection is provided together with automatic

pump seizure protection.

The gas valve solenoids are automatically checked for gas soundness.

IMPORTANT: Where back-flow prevention devices, including

water meters, are fitted the expansion of hot water into cold

water main can be prevented. This can result in a pressure

build-up that may cause damage to the boiler and household

devices such as showers, washing machines etc.

In these cases we recommend that a mini-expansion vessel

be fitted adjacent to the boiler in the cold water pipe.

2.10

Operation

Domestic Hot Water:

With a demand for hot water the burner

will light at its maximum setting and then automatically adjust

its output to maintain the temperature of the delivered water.

When hot water is no longer required, the burner will extinguish.

The fan and pump will continue to run for a short period to

dissipate the residual heat from the appliance.

Central Heating:

With a demand for heating the burner will light at

its minimum setting and gradually increase to give a controlled

temperature rise. When the required heating temperature is achieved

the output of the appliance is then automatically adjusted to

maintain the temperature of the system. The output can reduce

down to a minimum of 10.5 kW. If the system no longer requires

even the minimum output to maintain the desired room temperature

the burner will extinguish. The fan and pump will continue to run to

dissipate the residual heat from the appliance. The appliance will

remain off for a fixed period before re-lighting to automatically meet

the system requirements.

Domestic Hot Water and Central Heating:

The appliance will

supply heat to the central heating system as required. A demand for

domestic hot water at a tap or shower will override the central heating

requirement for the period of the domestic hot water demand. When

hot water is no longer required the appliance will return to the central

heating state and its normal mode of operation. The fan will continue

to run to dissipate the residual heat from the appliance as necessary.

3

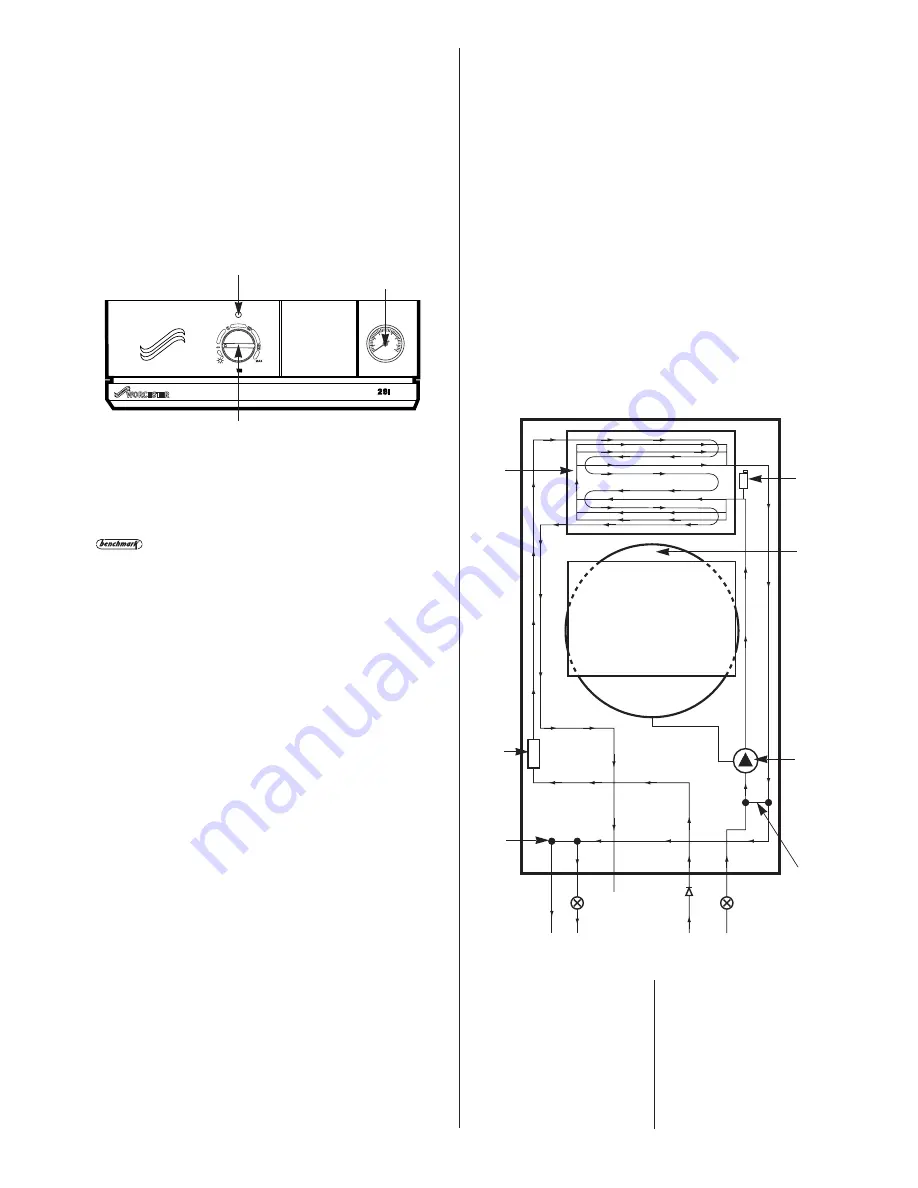

Fig. 1. Facia controls

1

2

3

1 Mains Indicator Light

2 System Pressure Gauge

3 Central Heating Temperature Control

Fig. 2. Water flow diagram.

1 2 4 5

3

6

7

8

9

10

11

12

1 Safety Discharge 10 Bi-thermal Gas to Water

2 C.H. Flow

Heat Exchanger

3 Domestic Hot Water Out 11 Domestic Water Flow

4 Domestic Cold Supply Turbine

5 C.H. Return 12 Pressure Relief Valve

6 Fixed By-pass

7 Circulating Pump

8 Sealed System Expansion

Vessel

9 Automatic Air Vent