SERVICING AND SPARES

6 720 803 599 (2012/06)

42

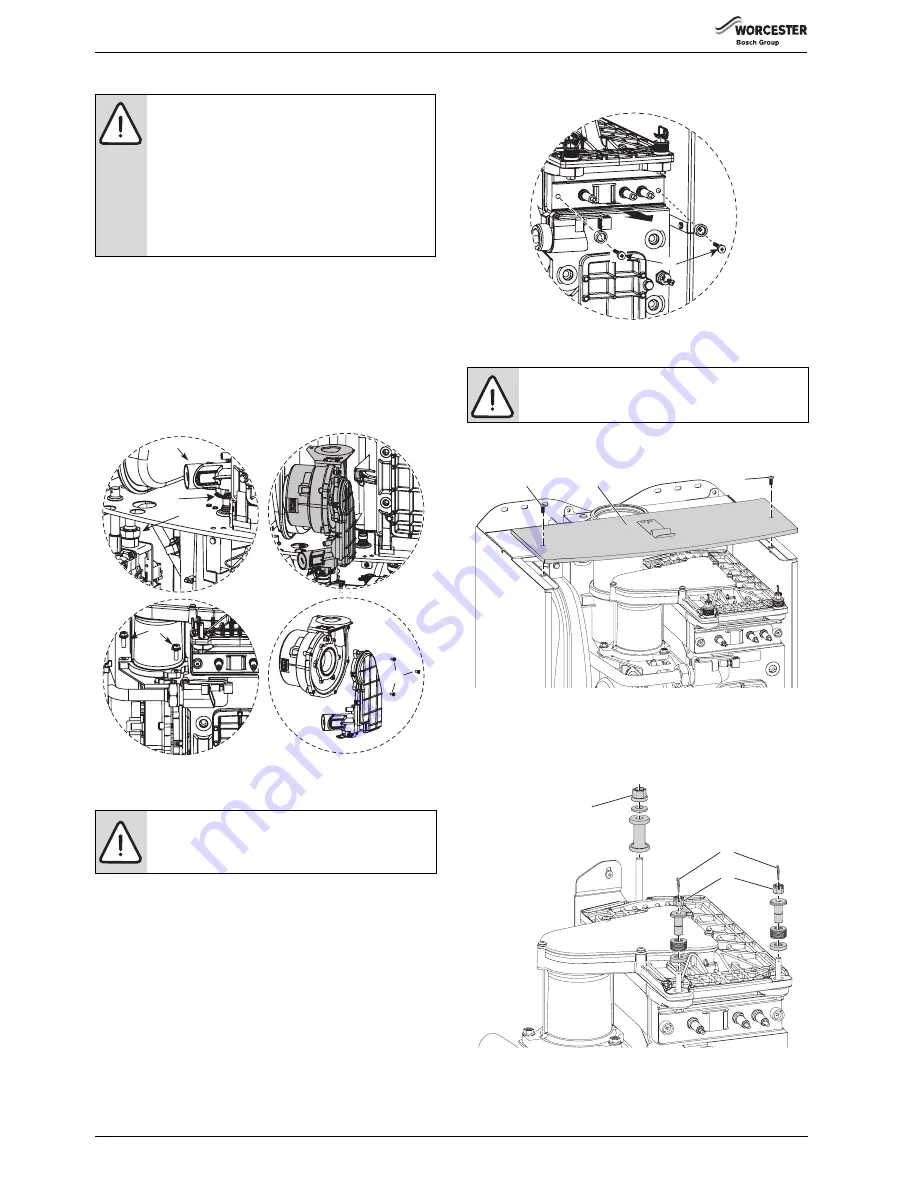

12. FAN ASSEMBLY

B

Remove electrical connector from fan.

B

Remove condensate trap (see page 37).

1. Undo the union connection (A) from the top of the gas valve.

B

Remove wire clip (B) from air/gas adjustment assembly (C) then pull

gas pipe down.

2. Unscrew two screws (D).

3. Remove fan from boiler.

4. Remove three screws retaining the air/gas adjustment assembly (E).

B

Reassemble with new fan ensuring that seals are correctly fitted.

Fig. 59 Fan assembly removal

13. ELECTRODE ASSEMBLY

B

Disconnect spark electrodes and flame sensor connection.

B

Remove two screws (F).

B

Remove spark/flame electrode assembly (G) from heat exchanger.

B

Inspect the spark/flame electrode assembly and ceramics for signs of

contamination or damage, replace as necessary.

B

If necessary, clean the spark/flame electrode assembly with a plastic

scouring pad.

B

Replace electrode gasket and heatshield.

B

Re-assemble with the new gasket and secure with the screws (F)

removed earlier.

Fig. 60 Electrode assembly

14. AIR/GAS MANIFOLD

1. Remove cover panel (A) by removing screws (B).

B

Check that the boiler is completely isolated from the gas supply.

Fig. 61 Top panel

2. Remove clips (C) and unscrew the two bolts (D).

B

Unscrew and remove the two hexagon screws (E) securing the fan.

B

Slacken fully the rear securing bolt (F).

Fig. 62 Release air/gas manifold

NOTICE:

Air/Gas ratio

B

After re-assembly the combustion must be checked

using the procedure in the section “Setting the air/gas

ratio.”

B

The setting of the gas ratio must be carried out by a

competent person.

Setting the air/gas ratio must not be attempted unless

the person carrying out the operation is equipped

with a combustion analyser conforming to BS 7927

and is competent in its use.

WARNING:

Electrode gasket

B

Do not remove the electrode assembly unless a new

gasket and heatshield are available for re-assembly.

B

C

A

D

2.

1.

6720647361-37.2W

o

E

8.

3.

4.

WARNING:

Air/Gas manifold

B

Do not remove the manifold unless a new gasket is

available for re-assembly.

13

G

F

6720647361-38.1W

o

A

B

6720647361-63.1Wo

B

1.

F

C

D

2.

6720647361-64.1Wo