Commissioning

Greenstar 4000 – 6 720 891 162 (2020/09)

46

Commissioning must not take place outside of the permissible pressure

range. If necessary:

▶ Identify the cause and rectify the fault.

▶ If this is not possible: isolate the device on the gas side and notify the

gas supplier.

▶ Exit the chimney sweep mode.

▶ Switch off the appliance, close the gas isolator, remove the pressure

gauge and tighten the screw.

▶ Refit the casing.

Gas pressure within the system

Combi appliances

▶ Running a hot water tap does not guarantee the appliance will

operate at maximum output throughout the test.

Natural Gas or LPG pressures.

The pressure drop from the meter or at the LPG gas supply to the gas

valve inlet test point must not be more than the values stated in table 21.

If the pressure drops are greater than shown in table 21, then this would

indicate a problem with the pipework or connections within the system.

NOTICE

▶

Do not continue commissioning until the correct gas pressure is

achieved with the appliance running at maximum output.

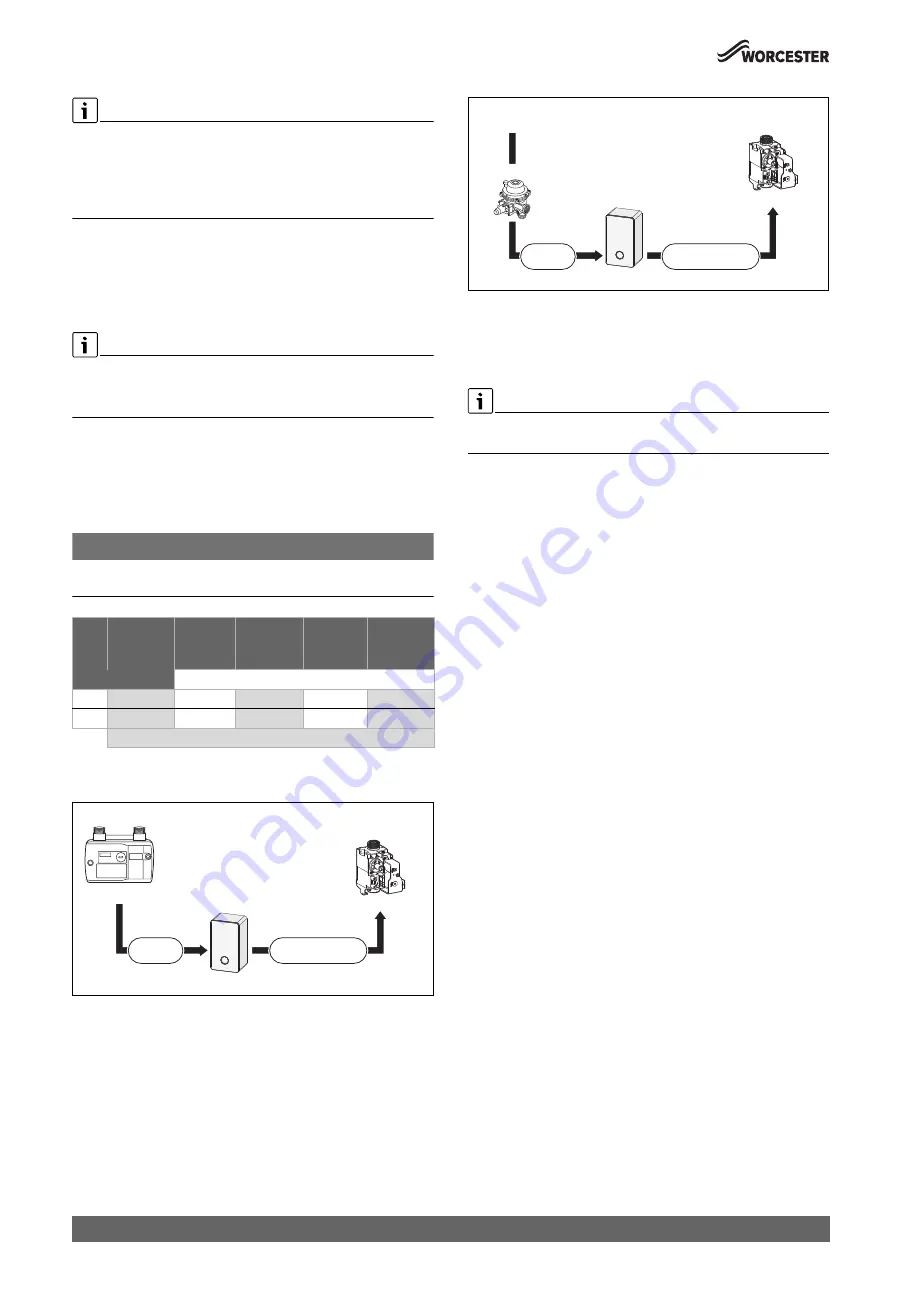

Table 21 Allowed mbar pressure drop

Gas supply pressure drop

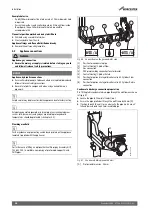

Fig. 65 Natural Gas pressures

[A]

Pressure loss across the appliance

[B]

Pressure reading at inlet test point

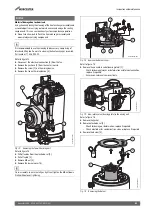

Fig. 66 LPG pressures

[A]

Pressure loss across the appliance

[B]

Pressure reading at inlet test point

6.6

Checking the gas rate

The appliance must be running at maximum output rate when

performing the gas rate check, (

chapter 6.4.1).

▶ The gas rate should be measured at the gas meter after the appliance

has been operating for

a minimum of 10 minutes

at maximum

output.

▶ Refer to Technical data section of this manual for the appliance gas

rates and CO/CO

2

ratios.

▶ Where a gas meter is not available (e.g. LPG) the CO/CO

2

must be

checked.

▶ Gas rate must be checked with the appliance in service, maximum

output test mode.

▶ Carry out gas rating as per the latest advice in the Gas Safety

(Installation and Use) Regulations.

▶ Ensure all other gas appliances are isolated when carrying out the gas

rate check on the appliance.

▶ Set the chimney sweep mode and start up the appliance at maximum

rated output.

– Ensure that the appliance has stabilised at maximum output.

▶ Where a gas meter is not available (e.g. LPG) the CO/CO

2

must be

checked to the units shown in the setting of the air/gas ratio.

▶ If pressure and gas rate are satisfactory press

ok

or

d

and the boiler

will return to normal operation.

– If left in the service mode the control will return to normal

operation after 15 minutes.

▶ Close the gas isolation valve.

▶ Remover the manometer.

▶ Re-seal the screw in the gas inlet pressure test point.

▶ Open the gas isolation valve and ensure there are no gas leaks.

6.7

Checking for gas leaks during operation

▶ Use an approved gas sniffer or leak detection fluid to check all

connections for possible leaks. Leak detection fluid must be certified

as a gas leak testing agent.

▶ Do not allow leak detection fluid to come into contact with the

electrical components.

Gas

Type

Meter/LPG

supply

Across

pipework

Appliance

inlet

Across

appliance

[A]

Gas valve

inlet test

point [B]

Allowed mbar pressure drop

NG

19 - 23

1

18 - 22

1.5

16.5 - 20.5

LPG

32 - 45

2.5

29.5 - 42.5

1.5

28 - 41

mbar range

0010012820-001

Natural Gas

Appliance inlet

18 - 22 mbar

Meter

19 - 23 mbar

Gas Control

valve

Inlet test point [B]

1.0 mbar

drop

Across appliance

drop [A]

0010012821-001

Appliance inlet

Inlet test point [B]

L.P.G.

29.5 - 42.5 mbar

0.5 mbar drop

Regulator

LPG Storage

32 - 45 mbar

Gas Control

valve

2.0 mbar

drop

Across appliance

drop [A]