Pre-Installation

Greenstar 4000 – 6 720 891 162 (2020/09)

12

4

Pre-Installation

NOTICE

Risk of damage to system or appliance!

Before installation

▶ All the following Pre-Installation sections must be read and

requirements met before starting appliance or flue installations.

Before continuing with the preparation and installation

If using the optional integral diverter valve kit ensure that:

▶ All of the required equipment for the installation is available

(

Diverter valve kit instructions for details).

▶ The integral diverter valve kit installation instructions are read in

conjunction with these instructions.

4.1

System preparation

4.1.1

Artificially softened water

The heating system must not be filled with water which has been treated

using an ion exchange (salt based) water softener. Where these water

softeners are installed, a permanent untreated water supply should be

provided to maintain pressure in the heating system.

A bypass must be provided at the water softener to comply with

BS:14743. Where a permanent untreated supply cannot be provided,

the system must be initially filled using the bypass provided at the water

softener. Occasional topping up of the system with artificially softened

water is acceptable. Inhibitor must be added to the system. The pH levels

must be between 6.5 and 8.0 at the time of commissioning. When a

permanent untreated supply is not provided to the heating system filling

point, the pH levels must be checked annually and recorded in the

service record.

NOTICE

Risk of damage to appliance!

▶ The heating system must not be filled with water which has been

treated using an ion exchange water softener.

▶ If the system is partially drained for maintenance or repair work, the

system must be refilled by utilising the bypass valve at the water

softener. The pH and inhibitor levels should be checked.

4.1.2

Water systems and pipework

Primary system plastic pipework:

• Any plastic pipework must have a polymeric barrier, complying with

BS 7921 and installed to BS 5955 with 600mm (minimum) length of

copper connected to the appliance.

• Plastic pipework used for under-floor heating must be correctly

controlled with a thermostatic blending valve limiting the

temperature of the circuits to approximately 50°C with 1000mm

(minimum) length of copper or steel pipe connected to the

appliance.

Primary system/connections/valves:

• Do not use galvanised pipes or radiators.

• All system connections, taps and mixing valves must be capable of

sustaining a pressure of 3 bar.

• Radiator valves should conform to BS 2767:10.

• All other valves should conform to BS 1010.

• It is best practice to fit Thermostatic Radiator Valves (TRV's) to all

radiators, except the area where the room thermostat is sited which

must be fitted with lockshield valves that are left open.

• If the circulating pump speed is fixed and system circulation can be

significantly adjusted or stopped by TRV's or zone valves, a system

bypass should be installed to give at least a 3 metre circuit when

activated. However; any appliance fitted with a modulating pump

may not require a system bypass.

• Drain cocks are required at all the lowest points on the system.

• Air vents are required at all high points on the system.

Primary system considerations - Combi & System appliances

Sealed system

• The CH sealed system must be filled using a WRAS approved filling

loop or comply with examples in section 4.1.4 "System fill".

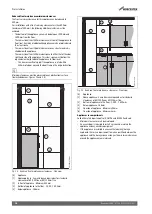

• Where the system volume is more than 100 litres or exceeds 2.5 bar

at maximum heating temperature an additional expansion vessel [2]

must be fitted as close as possible to the appliance in the central

heating return.

• Pressurise the extra expansion vessel [2] to the same value as the

built-in expansion vessel [1] (default pre-charge pressure is 0.75

bar).

Fig. 4

Additional expansion vessel

[1]

Appliance expansion vessel

[2]

Additional expansion vessel

[3]

Pressure relief discharge

[4]

Heating return

[5]

Heating flow

0010021117-001

3

4

5

2

1