Pre-Installation

Greenstar 4000 – 6 720 891 162 (2020/09)

16

Liquid Petroleum Gas (LPG):

Discharge rates for copper tube with 2.5mbar differential pressure

between the ends for LPG.

Table 10 Liquid Petroleum Gas (LPG)

Liquid Petroleum Gas (LPG):

▶ When using this table to estimate the Gas flow rate in pipework of a

known length, the effective length will be increased by 0.6m for each

90° elbow or tee and by 0.3m for each 45° bend or straight coupler.

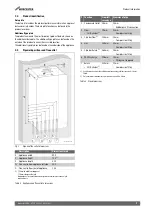

4.3

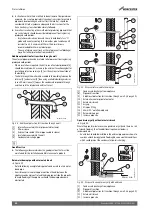

Appliance location and clearances

4.3.1

Appliance location

• Follow local regulations for the location within the property that the

appliance is to be installed.

• This appliance is only suitable for installing internally within a

property at a suitable location onto a flat, fixed rigid surface capable

of supporting the appliance weight.

• The appliance is not suitable for external installation.

• Protect installation area against dust and moisture.

No surface protection is required against heat transfer from the

appliance.

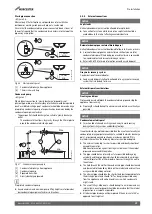

DANGER

Danger from explosive and flammable materials:

Storage of explosive and flammable materials.

▶ Do not store flammable materials (paper, curtains, clothing, primer,

paint, …) in proximity to the appliance.

DANGER

Danger to life from explosion!

An increased and permanent ammonia concentration may lead to stress

corrosion cracking on brass (e.g.gas valves, union nuts). As a result,

there is a risk of explosion from gas escaping.

▶ Do not use wall mounted gas boilers in rooms where there is an

increased or permanent ammoniac concentration (e.g. livestock

stables or storage room for fertilisers).

▶ If contact with ammonia is unavoidable, make sure that there are no

brass parts installed in the system.

NOTICE

Damage to appliance:

Contaminated combustion air.

▶ Do not use any cleaners containing chlorine or hydrogen halide (i.e.

spray cans, primers, cleaners, paint and glue).

▶ Do not store or use these substances in the appliance or room.

▶ Avoid the build-up of dust.

NOTICE

Damage to appliance:

Extreme temperatures may cause damage to the heating system.

▶ Ensure the appliance location’s ambient temperature is above 0 °C

and below 50°C.

NOTICE

Damage to system:

The heating system pipework can be damaged by frost if installed in an

internal unheated area, such as a loft, basement or garage.

The appliance internal frost protection only monitors the system water

temperature within the appliance to provide protection for the

appliance.

▶ Install a frost thermostat and pipe thermostat connected in series, to

protect the system pipework.

We recommend that the frost thermostat is sited in the coldest

unheated area in which pipework is located and that it is set to call for

heat at 5 °C. The Pipe stat should be located on whichever pipe is

furthest from the heated area where warmer water will be drawn from

considering the direction of flow, and set to end the demand at 15 °C.

▶ The system pipework in the internal unheated area should be

insulated.

▶ If the appliance is to be shut down for an extended period, drain the

central heating system.

Frost protection can also be achieved for systems with Worcester

weather compensating controls installed.

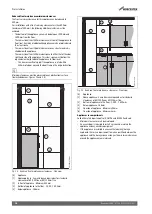

The appliance must be installed where:

▶ The area is well lit, allowing users to clearly see the appliance to carry

out any work or checks.

▶ An engineer can gain clear and safe access to work on the product or

component, including making adequate provision for visual

inspection of flues in voids.

▶ The homeowner can gain clear and safe access to the controls or to

check, top up or reset the appliance.

▶ Roof space installations must fully conform to BS 5410 part 1: roof

space installations.

▶ Products in roof spaces must have permanent fixed lighting, a

permanent fixed retractable ladder and a fixed floor area sufficient to

allow access for normal use and servicing around the product and

between the product and the access hatch.

We would also recommend that a remote pressure gauge and filling

loop are sited where the customer can gain easy access to assist with

checking and topping up.

Discharge rates for LPG (m

3

/hr & kW)

with straight horizontal copper tube

Tubing

Outside diameter

length (m)

15mm

22mm

28mm

kW

m

3

/hr

kW

m

3

/hr

kW

m

3

/hr

3

38.4

1.49

207

8.01

412

15.92

6

26.1

1.01

135

5.21

230

8.86

9

20.5

0.79

108

4.19

215

8.33

12

17.9

0.70

94

3.62

187

7.25

15

15.5

0.60

82

3.20

168

6.51

18

13.5

0.53

74

2.86

145

5.61

21

12.9

0.50

67

2.58

135

5.24

24

12.0

0.47

61

2.58

126

4.87