Pre-Installation

Greenstar 4000 – 6 720 891 162 (2020/09)

28

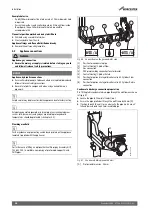

4.5

Condensate discharge

Full details on condensate discharge.

▶ Follow the latest version of

BS6798

and HHIC guidance.

For correct installation and trouble free operation of the appliance the

following advice should be followed:

1.

To minimise the risk of freezing, wherever possible: the

condensate drain should be installed internally.

2. All condensate pipework must ‘fall’ from the appliance by a minimum

of 3° (52mm per metre) to ensure adequate condensate flow.

3. The pipework route must allow air to be supplied back to the

appliance for correct operation.

4. Connection to a rainwater down pipe must include an air break.

Also:

• Assessment of the risk of the condensate pipe freezing must be

carried out and appropriate precautions taken where necessary.

This must take into account the specific site conditions.

• The condensate pipework connected to the condensate drain outlet

on the appliance should have a minimum internal diameter (ID) of

19mm.

• Keep external pipework as short as possible.

Further precautions against freezing must be taken if external pipe

runs exceed 3m.

• External pipework should have a minimum internal diameter (ID) of

30mm.

• Minimise the number of bends and connectors.

• Remove burrs and debris after cutting the pipe.

• Remove surplus solvent from the interior of the pipe.

• The condensate pipework shall be run in standard drainpipe

material, e.g. polyvinyl chloride (PVC), unplasticised poly vinyl

chloride (PVC-U), acrylonitrilebutadiene.styrene (ABS),

polypropylene (PP) or chlorinated poly vinyl chloride (PVC.C).

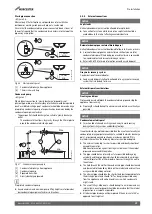

4.5.1

Appliance siphonic condensate trap

The appliance has a large capacity condensate trap reducing the risk of

condensate discharge pipework freezing up in prolonged cold

temperatures.

The expanded siphonic operation discharges every 10 to 20 minutes.

Resulting in:

• Increased velocity and flow rate.

• With less frequent siphonic actions per hour, the condensate

pipework is empty for longer.

• Significantly reducing freezing potential for a 48 hour period at

-15 °C, provided the installation parameters listed below are

followed.

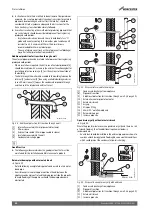

4.5.2

Condensate pipework

NOTICE

General consideration

▶ Where a new or replacement appliance is being installed, access to

an internal “gravity discharge” point should be one of the factors

considered in determining appliance location.

▶ Condensate pipe connection at the appliance:

The condensate pipe must have a nominally outside diameter of

22mm plastic pipe.

▶ Ensure there are no blockages in the pipe run.

▶ Ensure that the discharge method for the installation can effectively

handle the condensate waste from the appliance.

Condensate pipework - Unheated internal areas

NOTICE

Unheated internal areas.

Although the large volume siphon will reduce the risk of freezing,

condensate discharge may freeze in exposed areas during prolonged

cold temperatures.

▶ Internal pipe runs in unheated areas such as lofts, basements and

garages should be treated as external runs.

For additional information refer to “External Connections”

section 4.5.4.

4.5.3

Internal connections

Good Practice

▶ The following guidance indicates the good practices that must be

maintained for the Installation and Maintenance of a product.

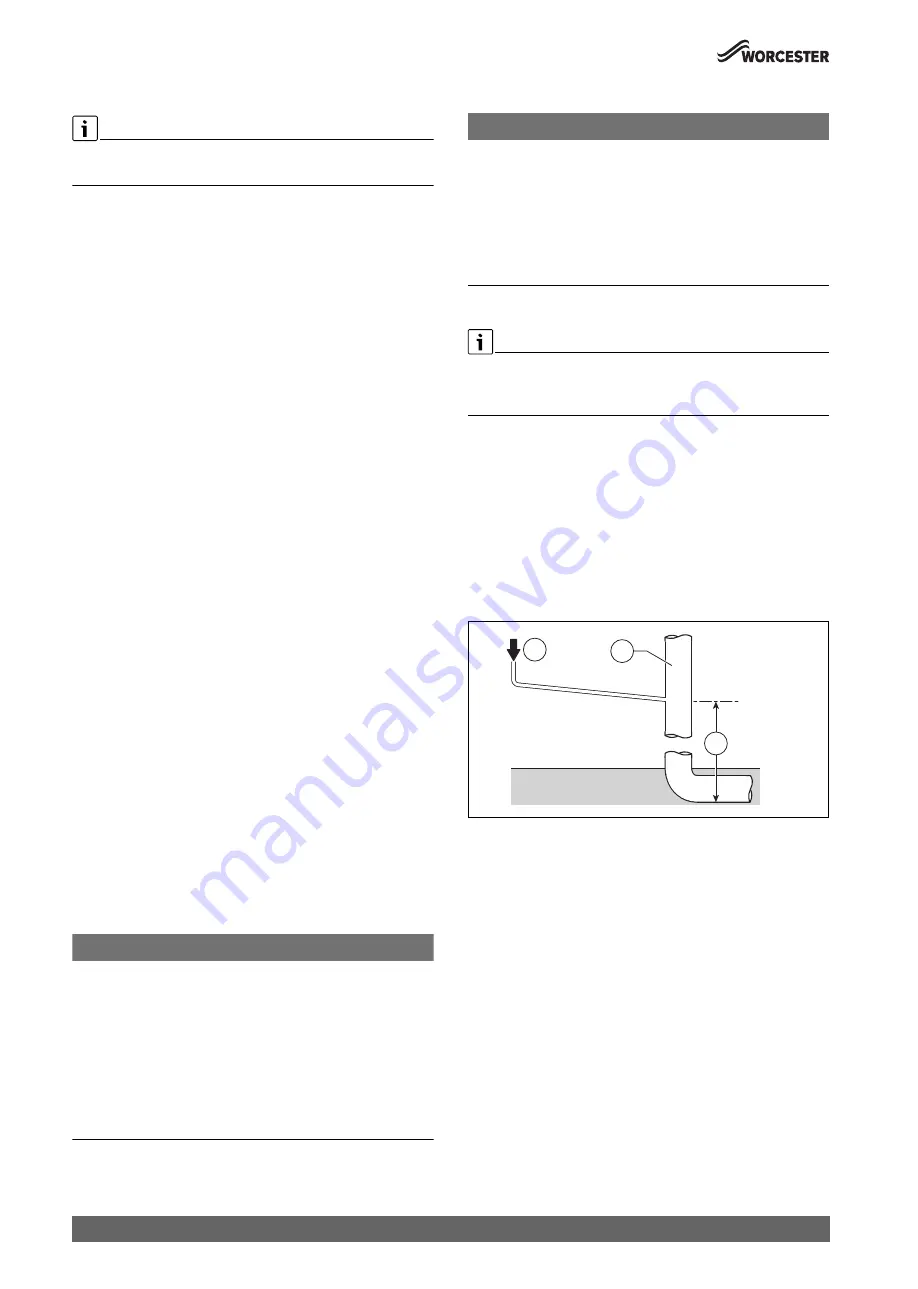

Soil stack connection

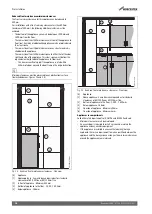

Figure 35

In order to minimise risk of freezing during prolonged cold spells, the

following methods of installing condensate drainage pipe should be

adopted.

Wherever possible, the condensate drainage pipe should be routed and

terminated so that the condensate drains away from the appliance under

gravity to a suitable internal foul water discharge point such as an

internal soil and vent stack. A suitable permanent connection to the foul

waste pipe should be used.

Fig. 35 Disposal to soil vent stack

[1]

Condensate discharge from appliance

[2]

Soil and vent stack

[3]

Minimum 450mm and up to 3 storeys

0010012746-002

2

1

3