Pre-Installation

Greenstar 4000 – 6 720 891 162 (2020/09)

30

▶ In situations where there are likely to be extremes of temperature or

exposure, the use of a proprietary trace-heating system for external

pipework, incorporating an external frost thermostat, should be

considered. All other guidance above and the instructions for the

trace heating system, should be closely followed.

▶ As well as trace heating, other methods for protecting pipework that

are run externally should be considered to prevent freezing during

prolonged cold periods.

– Insulation materials can be used, these should be of class “O”

grade with an outer coating that is weather proof and have a UV

resistant finish. A minimum of 19mm thick insulation is

recommended for 32mm external pipes.

– The use of a drain cover (such as those to prevent leaf blockage)

may offer further protection from wind chill.

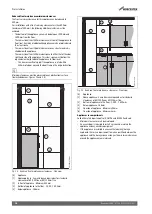

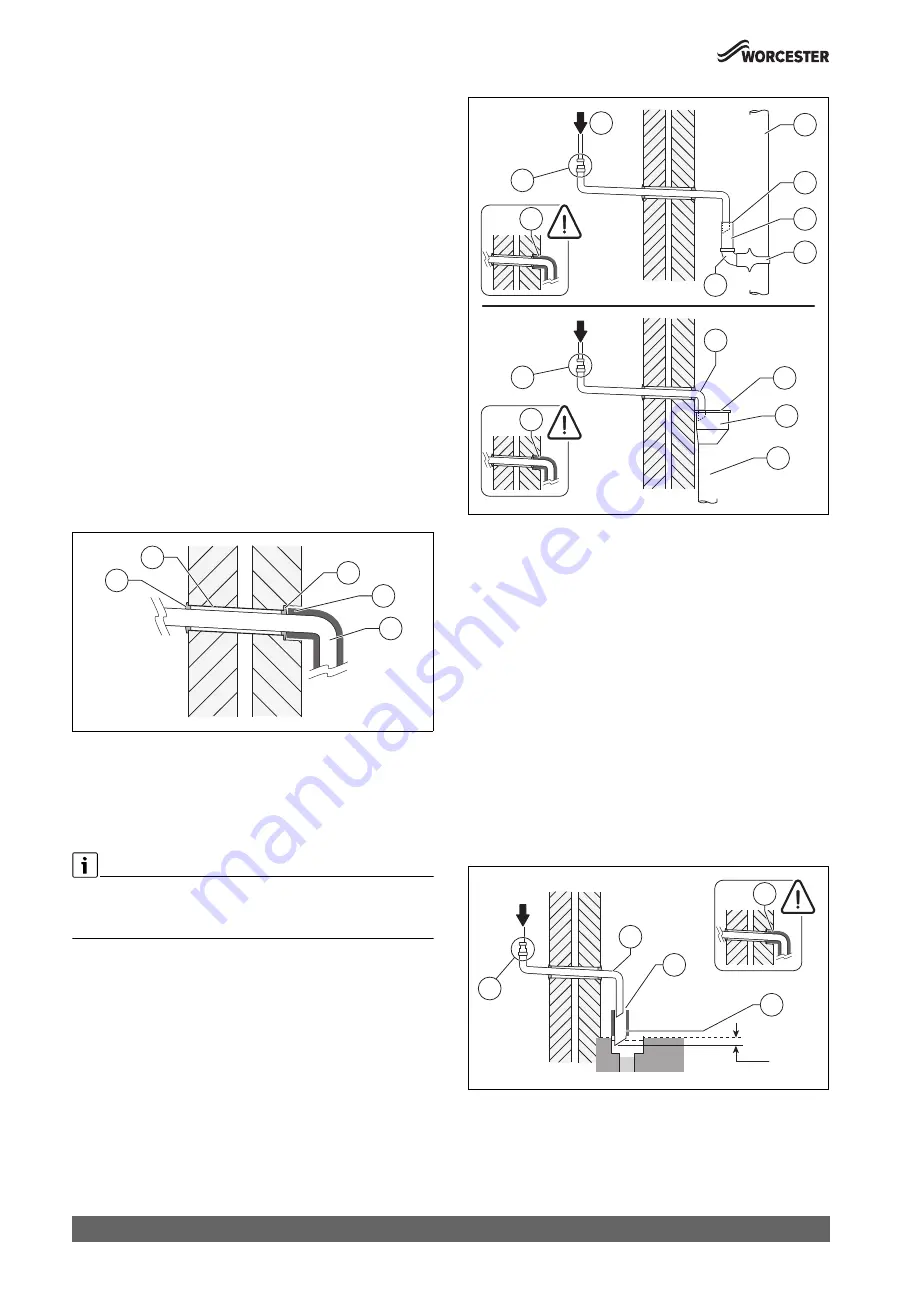

Additional protection for transition through a wall.

The external pipework can be insulated to help prevent freezing during

prolonged cold periods.

• Where insulation is required, the entire run of external pipework [5]

should be insulated with a recess in the external face allowing better

insulation protection coverage [4] as it transitions to the outside of

the building.

• The hole through the wall must be sealed to the building fabric on the

internal [1] and external [3] face using a suitable building material,

(use a 40mm sleeve [2] to pass the condensate pipework through

and then seal the internal and external faces).

Fig. 38 Additional protection for transition through a wall

[1]

Internal face sealed (32mm pipe sealed to sleeve)

[2]

40mm sleeve

[3]

External face sealed (32mm pipe sealed to sleeve)

[4]

Insulation recessed into the wall

[5]

Condensate discharge pipe

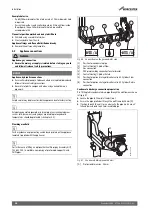

Good Practice

▶ The following guidance indicates the good practices that must be

maintained for the Installation and Maintenance of a product.

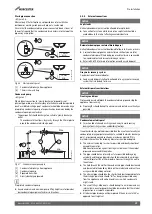

Rain water down pipe with external air break

Figure 39

• Refer to following example to dispose of condensate to a rain water

down pipe.

• An air break or rain water hopper must be utilised, between the

appliance condensate outlet and the drainpipe, outside the property,

to avoid flooding of the appliance should the downpipe become

obstructed.

Fig. 39 Disposal into rain water down pipe

[1]

Condensate discharge from appliance

[8]

Pipework transition

[9]

Additional protection for transition through a wall. (

[10] External rain water pipe to foul water

[11] External air break

[12] Air gap

[13] Strap-on fitting

[14] 43mm 90° male/female bend

[20] Rain water hopper

[21] Increase pipe size

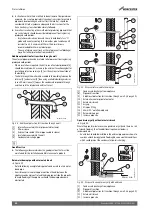

Open drain or gully with external air break

Figure 40

Where the pipe terminates over an open drain or gully and there is a risk

of ground flooding, then the additional requirement below is

recommended:

• An air break should be installed in the external pipework as shown to

avoid an airlock during ground flooding/adverse weather conditions

which could prevent the condensate from discharging.

Fig. 40 Disposal to open drain or gully with air break

[1]

Condensate discharge from appliance

[8]

Pipework transition

[9]

Additional protection for transition through a wall. (

[11] External air break

[21] Increase pipe size

0010026770-002

1

2

3

4

5

1

0010012784-003

1

8

8

10

11

20

12

10

12

13

21

14

9

9

25mm min.

1

0010012786-003

8

11

21

21

9