Pre-Installation

31

Greenstar 4000 – 6 720 891 162 (2020/09)

Condensate soak away considerations

Before deciding to use a purpose-made soak away the history of the

locality and the ability of the surrounding area to disperse the

condensate should be taken into account, e.g. areas prone to flooding

and ground with a high clay content can result in poor drainage with an

increased risk of water logging or freezing causing the condensate pipe

to become obstructed by water or ice and the boiler to shut down,

Although it is possible to increase the size of the soak away and the area

with limestone chippings in clay soil areas, if the clay content is high and

prevents effective dispersal of the condensate then a soak away may not

be a suitable means of condensate disposal and an alternative method

should be used.

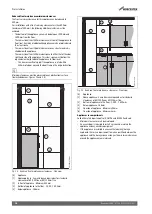

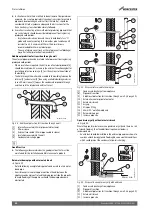

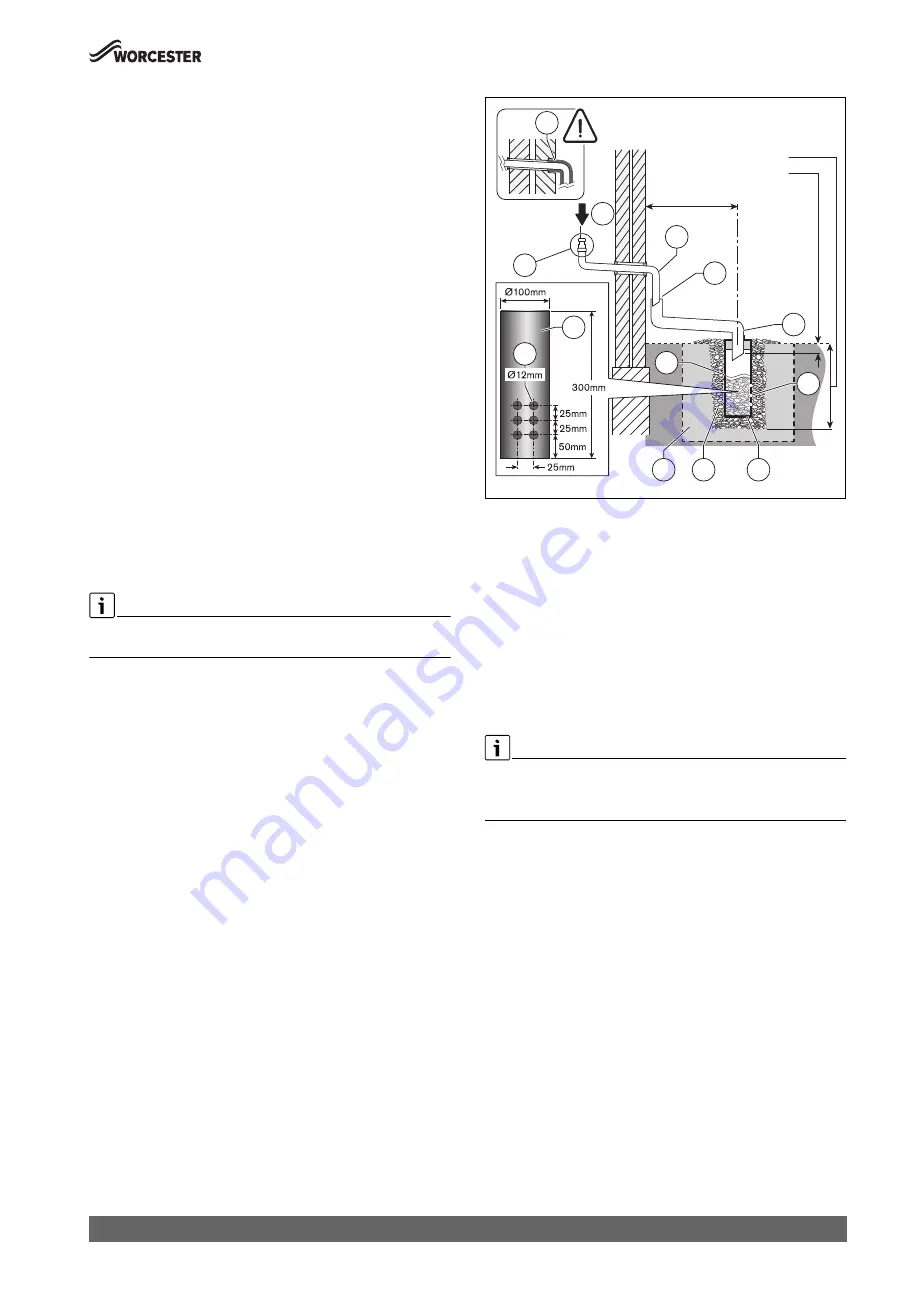

Condensate soak away with external air break

Figure 41

• Refer to following example to dispose of condensate to a soak away.

• The condensate soak away must be sited at least 500mm away from

building footings.

• The condensate drainage pipe may be run above or below the ground

to the soak away. The following example shows drainage pipe run

above ground.

• The soak away must use a minimum of a 100mm Ø plastic tube with

two rows of three 12mm holes on 25mm centres and 50mm from the

bottom of the tube. The holes must face away from the house.

• The tube must be surrounded by at least 100mm of limestone

chippings to a depth of 400mm.

• An air break must be installed in the external pipework as shown to

avoid an airlock during ground flooding/adverse weather conditions

which could prevent the condensate from discharging.

Minimum hole size for the condensate soak away must be 400mm deep

by Ø 300mm.

Fig. 41 Disposal to soak-away

[1]

Condensate discharge from appliance

[8]

Pipework transition

[9]

Additional protection for transition through a wall. (

[11] External air break

[15] 100mm minimum Ø plastic pipe

[16] Drainage holes

[17] Limestone chippings

[18] Bottom of sealed tube

[19] Increase size of soak away size and the area with limestone

chippings if in clay soil area.

Not recommended for high clay soil areas.

[21] Increase pipe size

Minimum Standard

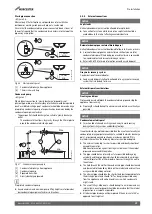

▶ The following guidance indicates the minimum standards that must

be maintained for the Installation and Maintenance of a product.

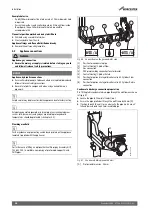

Appliances with large capacity condensate trap or CondenseSure

accessory or have trace heating fitted.

The need to insulate the pipework through the wall is not normally

required for appliances with a large capacity condensate trap or

CondenseSure/trace heating fitted for external runs under three metres.

These pipes should be sleeved though the wall and the insulation

recessed when used.

Cavity wall considerations:

• Whilst insulating the pipe through a typical external wall is unlikely to

be required for added protection against freezing in most

circumstances, it might be a consideration where the property is

located in particularly cold, exposed areas, has an uninsulated cavity

or perhaps an unusual construction where there is a larger than

normal cavity between the inner and outer wall.

Trace heating fitted:

• Check with trace heating manufactures instructions for additional

requirements.

500mm min.

25mm min.

400mm min.

15

16

0010012788-002

1

15

11

21

16

21

18

17

19

9

8