Commissioning

Greenstar 4000 – 6 720 891 162 (2020/09)

48

6.9

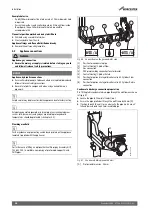

Checking flue integrity

Flue integrity check

▶ The combustion casing must be fitted whilst this test is carried out.

▶ Refit the test point plugs after the test has been completed.

The integrity of the flue system and performance of the appliance can be

checked via the flue turret/adaptor sample points.

Air inlet sample point location on flue turret/adaptor.

Fig. 68 Flue integrity check test point

[1]

Air inlet sample point

[2]

Flue turret air inlet blank plug (with retaining ring)

[3]

Flue adaptor air inlet blank plug

▶ With the appliance combustion casing on and the appliance running

at maximum output in chimney sweep mode

(

chapter 6.4 "Chimney sweep mode"), remove the blanking plug

[2 or 3] for the air inlet sample point [1].

▶ Insert the analyser probe into the air inlet sample point [1].

▶ Allow the readings to stabilise and check that:

– O

2

is equal to, or greater than 20.6%

– CO

2

is less than 0.2%

▶ If the readings are outside these limits then this indicates that there

is a problem with the flue system or combustion circuit.

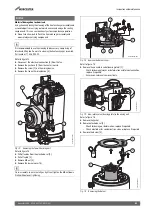

6.10

Flue gas analysis

NOTICE

Combustion testing

▶ Combustion testing must be carried out by a competent qualified

person. Testing must not be attempted unless the person carrying

out the combustion check is equipped with a calibrated Flue Gas

Analyser conforming to BS 7967 and is competent in its use.

Flue gas analysis

▶ Ensure that the gas inlet pressure has been checked and is

satisfactory.

▶ Refit the test point plugs after the test has been completed.

The flue gas analysis performance of the appliance can be checked via

the flue turret/adaptor sample points.

Refer to figure 69 for the location of the flue gas sample point on flue

turret/adaptor.

Fig. 69 Combustion test

[1]

Flue gas sample point

[2]

Flue turret flue gas blank plug

[3]

Flue adaptor flue gas blank plug

The CO and combustion ratio are checked;

• In chimney sweep mode at maximum output.

• In chimney sweep mode at minimum output.

Appliance to maximum output

▶ Set the appliance running at maximum output in chimney sweep

mode (

chapter 6.4 "Chimney sweep mode").

Appliance to minimum output

▶ Set the appliance running at minimum output in chimney sweep

mode (

chapter 6.4 "Chimney sweep mode").

– Allow the appliance to stabilise at minimum output.

Measuring the CO and combustion ratio.

▶ Remove the blanking plug [2 or 3] for the flue gas sample point [1].

▶ Insert the analyser probe into the flue gas sample point [1].

– Ensure that the probe reaches the centre of the flue gas exhaust,

adjust the cone on the probe so that it seals the sample point and

correctly positions the end of the probe.

▶ Check the CO and combustion readings.

Internal diverter valve

: When running in maximum output in test mode,

and the water temperature is 74°C or less, the appliance will operate

both the central heating and DHW circuits with the internal diverter valve

in the mid position. It will be necessary to run sufficient water through

the DHW circuit to ensure that the appliance will not cycle on low heating

demands. This is to allow sufficient time for the setting procedure. When

the water temperature reaches 75°C the diverter valve will switch to CH

only and will only return to the mid position if the temperature is 65°C or

less.

External diverter valve/s:

When the internal diverter valve is not fitted,

it is recommended to position the external diverter valve in the central

heating position.

0010015568-001

1

2

3

0010015569-001

1

3

2