Regulations

7

Greenstar 4000 – 6 720 891 162 (2020/09)

2

Regulations

Installation regulations

Current Gas Safety (Installation and Use) Regulations:

All gas appliances must be installed by a competent, registered gas

engineer, such as a Gas Safe registered engineer or British Gas engineer

in accordance with the current regulations.

Failure to install appliances correctly could lead to prosecution.

The appliance must be installed in accordance with, and comply to, the

current:

▶ Gas Safety Regulations

▶ IET Regulations

▶ Building Regulations (England)

▶ Building Regulations (Wales)

▶ Building Standards (Scotland) (Consolidation)

▶ S.I. No. 183 and 292 - Energy Performance of Buildings Regulations

(Ireland; current version)

▶ Health and Safety Document 635 (The Electricity at Work

Regulations 1989) and any other local requirements

▶ EU Regulations No. 811/2013 - Energy Labelling

Building Regulations Part L1A (Current version) - new dwellings

If the installation is in a new build property or it is a first time installation

in an existing property, the heating systems must conform to current

building regulations Part L1A.

The exception to this are single storey, open plan dwellings where the

living area is more than 70% of the total usable floor area. Then this type

of dwelling can be controlled as one zone.

An alternative would be individual electronically controlled TRVs.

For dwellings with a floor area over 150m

2

, separate time and

temperature control for each zone is required. It is best practice to fit

Thermostatic Radiator Valves (TRV's) to all radiators except the area

where the room thermostat is sited.

Building Regulations Part L1B (Current version) - existing dwellings

For appliance replacements on an existing system, it is not necessary to

zone the upstairs and downstairs separately, compliance with the zone

requirements can be achieved by a single room thermostat or

programmable room thermostat.

While the system is drained down, it is best practice to fit Thermostatic

Radiator Valves (TRV's) to all radiators except the area where the room

thermostat is sited.

British Standards

Where no specific instruction is given, reference should be made to the

relevant British Standard codes of Practice.

• BS7074:1

– Code of practice for domestic and hot water supply

• BS6891

– Installation of low pressure gas pipework up to 28mm (R1)

• BS5546

– Installation of gas hot water supplies for domestic purposes

• EN12828

– Central heating for domestic premises

• BS5440:1

– Flues and ventilation for gas appliances of rated heating not

exceeding 70kW (net): Flues

• BS5440:2

– Flues and ventilation for gas appliances of rated heating not

exceeding 70kW (net): Air Supply

• BS7593

– Treatment of water in domestic hot water central heating systems

• BS6798

– Installation of gas fired boilers of rated input up to 70kW (net)

• BS7671

– IET Wiring Regulations

Irish Standards

The current relevant Irish standards should be followed, including:

• ECTI

– National rules for electrical installations

• IS 813

– Domestic Gas Installations

LPG Installations

An appliance using LPG must not be installed in a room or internal space

below ground level unless one side of the building is open to the ground.

Timber framed buildings

Where the appliance is to be fitted to a timber framed building the

guidelines laid down in BS5440: Part 1 and IGE “Gas Installations in

Timber Frame Buildings” should be adhered to.

Water supply:

All seals joints and compounds (including flux and solder) and

components used as part of the secondary domestic water system must

meet the requirements of the WRC and hold approval by a notified body,

e.g. WRAS. The installation must also comply with the requirements of

Part G of the Building Regulations.

CH Water

Salt based artificially softened water must not be used to fill the central

heating system.

3

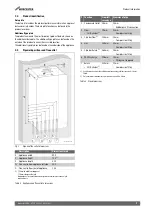

Product Information

Appliance features

• Aluminium-silicon heat exchanger.

• Low NOx emissions.

• Direct burner ignition.

• Built-in appliance frost protection.

• Built-in fault finding diagnostics.

• Zero pressure governor gas valve with fully modulating fan.

• Display for appliance status and access to diagnostics, system and

commissioning parameters.

• Four hour memory retention after power interruption.

• Low energy modulating pump.

• Condensing in CH and DHW modes.

• Eco mode, to increase hot water cylinder hysteresis.

1)

• Galvanised steel wall mounting frame provides vertical pipe route

behind the appliance.

• Compatible with Worcester standard and intelligent controls.

– See accessories list for available controls.

• Condensfit II flue systems 60/100 and 80/125 mm allows plume re-

direction.

• Condensfit II flue systems 60/100 allows the ability to attach plume

management kit.

• Front accessible components for maintenance.

• Large volume siphon mitigating the risk of condensate freezing.

• Digital Pressure sensor

1) Function available when optional integral diverter valve kit is fitted.