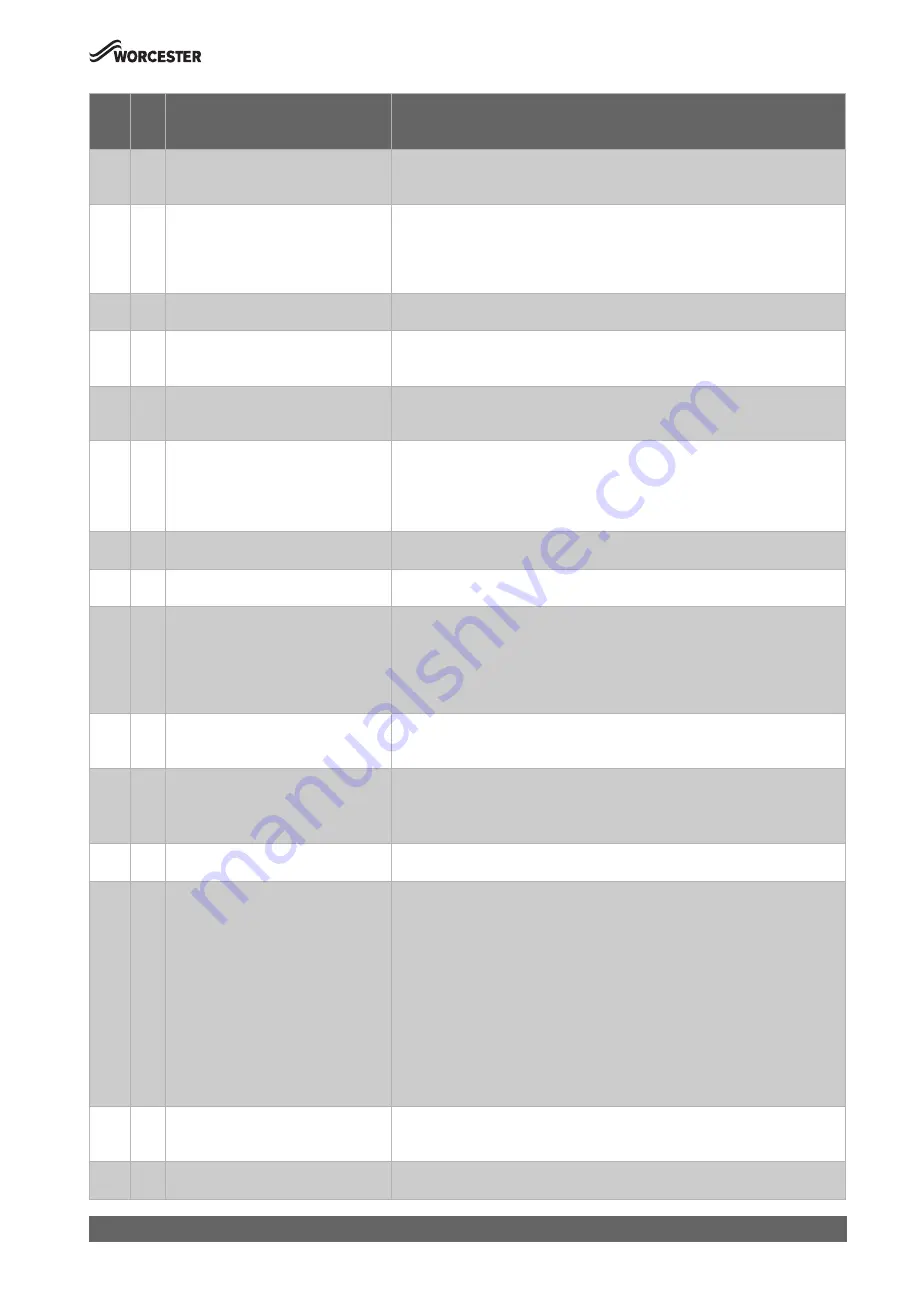

Fault finding and diagnosis

73

Greenstar 4000 – 6 720 891 162 (2020/09)

263

V

System fault boiler electronics / basic

controller

▶ Reset appliance electronics (factory reset).

▶ Check the electrical connections on the board (check for loose wires etc.).

▶ Replace the control unit.

265

B

Heat demand lower than energy supplied

Operating message, is not a fault.

• The boiler's ignition sequence alone is sufficient enough to maintain room

temperature.

• The modulating heat demand is higher than the minimum modulation factor of the unit.

The unit switches to proportional control.

268

O

Relay test was activated

Operating message, is not a fault.

• Appliance in component test mode.

269

V

Flame monitoring

▶ Restart the appliance to see if the problem re-occurs.

▶ Check the electrical connections on the board (check for loose wires etc.).

▶ Replace the control unit (PCB).

273

B

Operation of burner and fan interrupted

Operating message, is not a fault.

• The burner and fan have been running continuously for 24 hours and have been shut

down briefly for an appliance electronic inspection

281

B

Operation of burner and fan interrupted

▶ Check primary system water pressure.

▶ Check for air in the system and vent the pump.

▶ Check for circulation within heating system.

▶ Check hydraulic connections to the pump.

▶ Check wiring and operation of the pump, replace if necessary.

283

O

Burner starting

Operating message, is not a fault.

• Burner is starting.

284

O

Opening air/gas ratio control valve/oil

solenoid valves

Operating message, is not a fault.

• Gas valve is opening.

305

O

Boiler in hot water anti-cycle mode

Operating message, is not a fault.

• Anti-cycle mode, domestic hot water post-heat function. Following a domestic hot

water demand the boiler runs for 30 seconds or until the target temperature is met.

– Diverter valve is held in the hot water position for a period of time.

– If no domestic hot water demand is requested then check for false demands on the

cold water inlet.

306

V

Flame signal after closing the fuel supply

▶ Check the gas valve, replace if required.

▶ Check electrodes and connecting leads, replace if required.

▶ Replace the appliance electronics.

353

O

Test non-volatile lockout

Operating message, is not a fault.

• If the boiler has been operating for 24 hours without a 20-minute off period, the boiler

will not respond for a period of time whilst it undertakes diagnostics checks on the fan.

357

O

Flame signal after closing the fuel supply

Operating message, is not a fault.

• Venting/air purge program has been automatically activated.

358

O

Anti-seizing functn. active

Operating message, is not a fault.

• Blocking protection for the heating pump and diverter valve active.

– The purpose of component kick is to ensure that hydraulic components such as

pumps will not get stuck by giving these functional components a “kick”, i.e. they

are briefly turned on after a period of inactivity.

– After power up every 24 hours the appliance will do a component kick, where the

pump will run for 10 seconds.

– If the appliance is already in a CH or DHW heat request, these heat demands will be

prioritised over component kick. But once the heat demand has ended the

component kick will take place.

– If this causes nuisance then please power the appliance off and on again at a more

suitable time; the daily kick will then occur at the time the appliance is turned on

again.

360

V

System fault boiler electronics / basic

controller

▶ Wrong code plug is inserted.

▶ Check the code plug is not damaged.

▶ Replace the code plug if required.

362

–

Boiler identification module or boiler

electronics faulty

Is not a fault.

• Service plug detected.

Fa

ult

co

de

Fa

ult

ca

te

go

ry Fault text on the display, description

Remedy