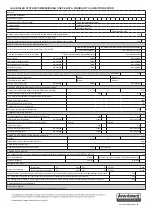

Fault finding and diagnosis

77

Greenstar 4000 – 6 720 891 162 (2020/09)

2951 V

Loss of flame too many times

Maximum unexpected flame losses exceeded.

▶ Refer to the blocking error(s) that lead to this locking error. Check the fault history on

appliance.

▶ Possible incomplete purging of gas pipe.

▶ Could also indicate a wide variety of issues such as undersized pipework or gas

pressure dropping off, incorrectly routed condensate discharge, incorrectly sited

flues, incorrectly wired etc.

2952 V

Internal fault when testing the ionisation

signal

▶ Perform reset.

▶ If fault persists, replace control unit.

2957 V

Boiler electr. system fault

▶ Reset appliance electronics (factory reset).

▶ Check the electrical connections on the board (check for loose wires etc.).

▶ Replace the control unit.

2961 V

No fan signal available

▶ Check the mains voltage to the fan.

▶ Check the fan harness for continuity and replace if required.

▶ Check the pulse width modulation (PWM).

▶ Replace the fan.

▶ Replace the PCB.

2962 V

No fan signal available

▶ Check the mains voltage to the fan.

▶ Check the fan harness for continuity and replace if required.

▶ Check the pulse width modulation (PWM).

▶ Replace the fan.

▶ Replace the PCB.

2963 B

The heat exchanger sensor or both supply

and heat exchanger sensors are defect

▶ Check the flow through the appliance and the system is filled.

▶ Check for air locks in the system and purge if required.

▶ Check the heat exchanger sensor (primary thermistor) and the plug connected to

temperature sensor.

▶ Check the resistance of the temperature sensor and replace if required.

▶ Check the continuity of the temperature sensor harness and replace if required.

2964 B

Flow rate in heat exchanger too low

▶ Check the flow through the appliance and that the system is filled.

▶ Check for air locks in the system and purge if required.

▶ Check the heat exchanger sensor (primary thermistor) and the plug connected to the

temperature sensor.

▶ Check the resistance of the temperature sensor and replace if required.

▶ Check the continuity of the harness and replace if required.

2965 B

Flow temperature too high

▶ System is not filled with water.

▶ No water flow, because CH system is closed.

▶ No water flow, because pump is not operating correctly.

▶ Check flow through appliance and system pressure.

▶ Check for air locks in the system. Purge if required.

▶ Check isolation valves.

2966 B

Flow temperature rise in heat exchanger too

rapid

▶ System is not filled with water.

▶ No water flow, because CH system is closed.

▶ No water flow, because pump is not operating correctly.

▶ Check pump is operating freely check voltage to pump.

▶ Check the isolation valves.

▶ Check for air locks in the system, purge if required.

▶ Check flow through appliance and system pressure.

2967 B

The temperature difference between supply

temperature sensor and temperature

sensor at heat exchanger is too large

▶ Check the flow through the appliance and that the system is filled.

▶ Check for air locks in the system and purge if required.

▶ Check the isolation valves, ensure they are open.

▶ Check the pump is operating freely and check the voltage to the pump.

▶ Check the heat exchanger sensor and the flow sensor are making correct contact with

the heat exchanger assembly/pipework.

▶ Check the heat exchanger sensor for break or short circuit, replace if required.

▶ Check the resistance of the supply sensor for break or short circuit, replace if required.

▶ Check the continuity of harness, replace if required.

Fa

ult

co

de

Fa

ult

ca

te

go

ry Fault text on the display, description

Remedy