1.1

General installation information and advice may be obtained

from the Oil Firing Technical Association for the Petroleum

Industry (OFTEC). Training courses are also offered by OFTEC,

leading to inclusion on their list of registered engineers.

1.2

The appliance should be installed by a competent person.

The person installing the appliance should be aware of the

Health and Safety at Work Act and take appropriate action to

ensure that the regulations are adhered to.

1.3

A qualified engineer must commission the appliance before

handing over to the user. OFTEC recommends the use of

registered engineers for the commissioning of oil-fired burners.

1.4

The manufacturers notes must not be taken, in any way, as

overriding statutory obligations.

1.5

The compliance with a British Standard does not, of itself,

confer immunity from legal obligations. In particular the

installation of this appliance must be in accordance with the

relevant requirements of the following British Standards and

regulations in respect of the safe installation of equipment.

BS 5410: part 1: 1997 Code of practice for Oil Fired Boilers.

BS 799: part 5: 1987 Specification for Oil Storage Tanks.

BS 7593: 1992 Code of Practice for treatment of water in

domestic hot water central heating systems.

BS 5449: part 1: 1990 Code of practice for Central Heating for

Domestic Premises.

BS 7074: part 1: 1989 Application, selection and installation of

expansion vessels and ancillary equipment for sealed water

systems.

BS 7671: IEE Wiring Regulations, current edition.

The Building Regulations Part J England and Wales; Part F

Section III Scotland; Part L Northern Ireland.

Local water company bye-laws.

The Control of Pollution (Oil) Regulations.

1.6

To ensure that the installation will perform to the highest

standards, the system and components should conform to those

mentioned in the instructions.

2.1

The Worcester Bosch range of appliances covered in these

instructions have been designed to serve domestic central

heating and hot water requirements ranging from 15 kW to

32 kW ( 51,000 Btu/h to 109,000 Btu/h ) and may be used

on sealed or open vent primary systems.

2.2

The appliances are factory set to burn 28 second Kerosene

heating oil and the output can be altered to suit the application

by adjusting the burner as specified in tables 2 to 4.

2.3

The appliances may be converted to burn 35 second Gas Oil

by changing the nozzle and burner settings as specified in tables

2 to 4.

2.4

A flueless kit is available which allows the user to dispense

with the need for a conventional chimney. The kit incorporates a

silencer which eliminates excessive combustion noise.

Note: It is a mandatory requirement of the building

regulations that only 28 second kerosene is used on low

level discharge flues.

3. Technical Data

2. General Information

1. Installation Regulations

2

1.

Installation Regulations ...........................................Page 2

2.

General Information .................................................Page 2

3.

Technical Data...........................................................Page 2

4.

Siting the Appliance .................................................Page 5

5.

Removal of the Cabinet............................................Page 5

6.

Air Supply..................................................................Page 5

7.

Flue System...............................................................Page 5

8.

Oil Supply ..................................................................Page 7

9.

Heating and Hot Water System...............................Page 8

10. Electrical ....................................................................Page 10

11. Installation ................................................................Page 12

12. Commissioning the Appliance ................................Page 13

13. Instructions to the User ...........................................Page 15

14. Routine Cleaning and Inspection............................Page 16

15. Short Parts List..........................................................Page 17

16. Fault Finding .............................................................Page 18

Contents

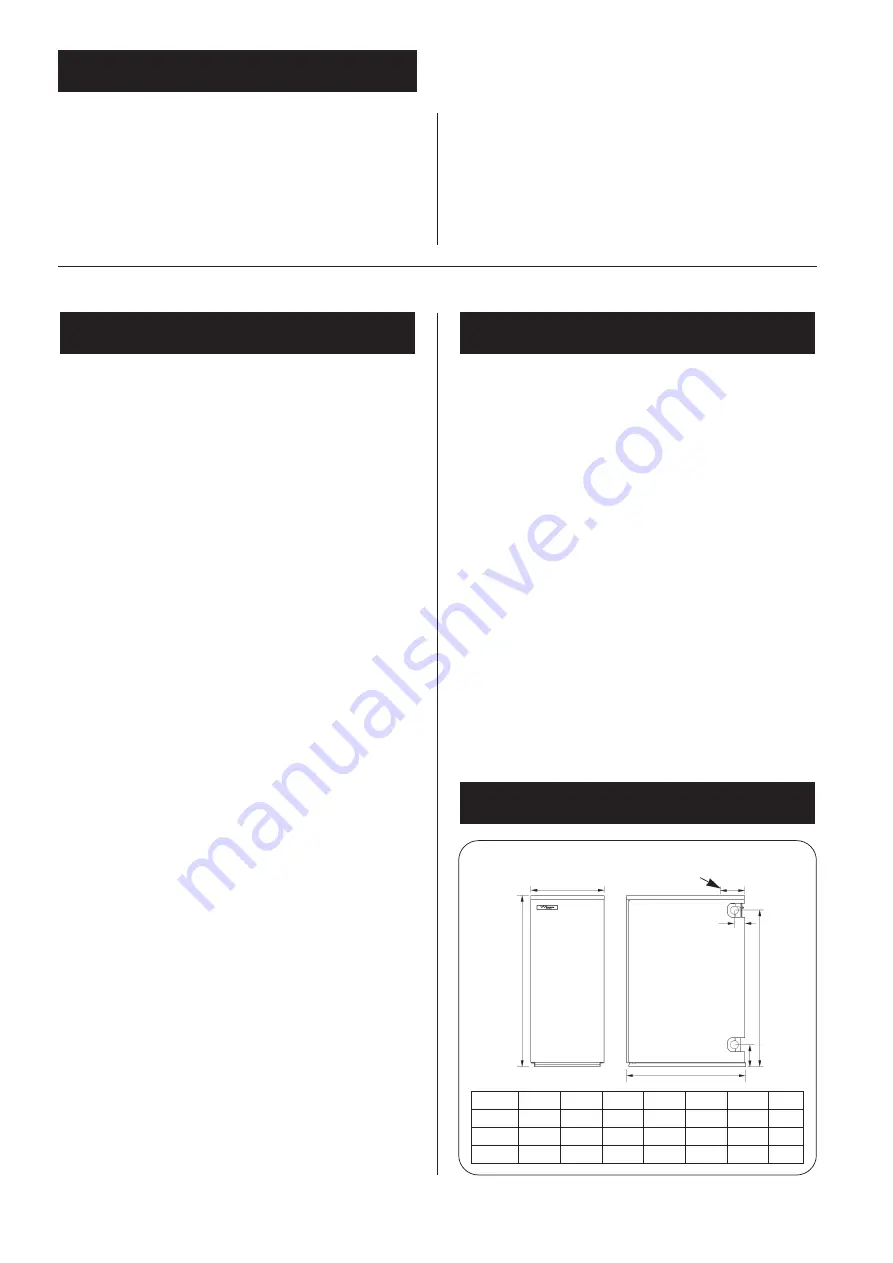

Fig. 1. Principal Dimensions

Model

A

B

C

D

E

F

G

50/70

370

600

855

780

110

92

57

70/90

370

600

855

780

110

92

57

90/110

520

600

855

775

110

92

57

A

C

D

G

F

Flue centre

E

B

Summary of Contents for 70/90

Page 19: ...19 NOTES ...