11.1

After unpackaging the appliance it is recommended that all

cabinet panels are removed, as described in Section 5, and

stored in a safe place to avoid damage during installation and

allow easy inspection for any leaks after the system has been

filled.

11.2

Remove the burner as described below and store in a safe

place until the appliance is ready for commissioning.

(a) Conventional Flue Appliance (CF/LLD).

1.

Remove the burner plug-in connector by removing the

electrical facia and pulling the three pin connector free. Slide the

locating bush from the electrical box.

2.

Remove the burner from the boiler by slackening the two M6

retaining screws located in the burner housing ring and pulling

the burner clear. This will require the use of a 5mm allen key.

(b) Room Sealed Balance Flue Appliance (RS).

1.

Remove the burner box cover by pulling forwards to release the

ball studs. This will be found easier by pulling on the one side of

the handle first to release two of the ball studs and then repeating

on the other side. Take care not to pivot the remaining two ball

studs too far around as this will cause damage to the spring clips.

2.

Remove the burner plug-in connector by removing the

electrical facia and pulling the three-pin connector free. Slide the

locating bush from the electrical box.

3.

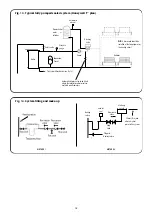

Push the electrical lead grommet back through the burner

surround box and feed the lead through the hole until the burner

plug-in connector reaches the burner box. Insert one of the

burner plug-in connector pins through the hole into the burner

box as shown in Fig. 17. Gently push on top of the burner plug-in

connector at the same time guiding the electrical cable through

the hole.

4.

Remove the burner from the boiler by slackening the two M6

retaining screws located in the burner housing ring and pulling

the burner clear. This will require the use of a 5mm allen key.

11.3 Flue system installation.

Install the appliance flue system as described in Section 7.

11.4 Heating system installation.

Before the appliance is fitted to the heating system

flush the system and mains water supply.

1.

Plumb the boiler into the central heating system.

2.

Check that all unused sockets have been plugged.

3.

Fill the system and vent all radiators and high points to

remove air from the system.

4.

Check the boiler and all pipework connections for leaks.

5.

The primary system should be flushed and treated in

accordance with the recommendations of BS 7593.

11.5 Oil supply installation

(See Figs. 9 to 11).

NOTE:

Never route the oil supply pipe/hose directly below the

combustion chamber base.

NOTE:

Connection of rigid copper pipe to the oil pump is not rec-

ommended. Connection to the oil pump should be made with

flexible oil hoses.

Conventional flue appliance (CF/LLD).

1.

Fit the oil supply pipe as described in Section 8. The pipe can

be routed down either side of the boiler in the gap between the

base tray and the boiler shell.

NOTE:

Never use soldered joints on oil supply pipes as this could

cause a hazard in the case of a fire.

2.

Fit an isolating valve at the end of the oil line close to the burner

and ensure that the valve is closed. Continue from step 11.5 (b) 5.

Room-sealed balanced flue appliance.

(a) Single pipe suction lift with de-aerator.

For connection of single pipe suction lift with de-aerator follow

the proceedure as for a double pipe system as described below.

(b) Double pipe system oil return pipe.

1.

Remove the isolating valve bulkhead fitting by unscrewing

the locknut on the underside.

2.

Remove the blind grommet from the fixed burner surround

box and discard.

3.

Replace the blind grommet with the open grommet supplied

in the plastic bag.

4.

Slacken the pipe retaining clip screw located directly below

the grommet hole. When using 12mm copper pipe replace the

clip with the larger one supplied.

5.

Bend a piece of 10mm or 12mm copper tube ( as selected ) to

the correct profile to allow the pipe to be fed down the side of

the appliance. Make a slight chamfer on the end of the pipe to be

fed through the grommet to facilitate easy insertion.

6.

Lubricate the grommet hole with vaseline (or butter etc.) and

slide the pipe through the hole, supporting the grommet on its

underside to prevent it dislodging.

7.

Feed the pipe through the retaining clip, allowing approximately

80 mm of pipe to project beyond the clip, and tighten the retaining

screw. Take care not to overtighten the screw!

8.

Hold the pipe at the retaining clip and gently pull the pipe

forward sufficiently to allow a compression to

1

/

4

inch BSP female

fitting to be fitted for connection to the oil return flexible hose.

9.

Connect the fitting to the pipe and fit a

1

/

4

inch BSP taper thread

flexible hose, ensuring a good seal using PTFE tape or suitable oil

sealing compound. The flexible hose should have a

1

/

4

inch BSP

rotating union taper fitting at the other end with a 90 degree bend

and

1

/

4

inch BSP nipple for connection to the oil pump.

10.

Replace the isolating valve bulkhead fitting.

11.

Fit the oil supply pipe as described in the following section.

(c) Single pipe system oil supply pipe.

1.

Bend a piece of 10mm or 12mm copper tube (as selected) to the

correct profile to allow the pipe to be fed down the side of the appli-

ance. The pipe may be routed along either the right or left hand

side of the boiler as required. When using 12mm pipe fit a 12mm

to 10mm compression coupling and connect to the valve with a

short piece of 10 mm pipe, otherwise connect direct to the valve.

Note:

never use soldered joints on oil supply pipes as this could

cause a hazard in the case of a fire.

2.

Route the pipe back to the oil supply tank ensuring that it is

hard against the boiler, to allow installation of the side panel.

3.

With the isolating valve in the correct orientation tighten the

back-nut.

4.

Turn the isolating cock fully clockwise to close the valve.

5.

Open the main oil supply valve at the tank and check for any

leaks.

6.

Place a suitable container below the bulkhead fitting and

open the valve.

11. Installa

tion

18

Fig. 17. Removal of burner plug-in

connector burner box

Burner plug-in

connector

Burner box

Electrical lead