Pre-Installation

21

Worcester Commercial Boiler Series – 6720814332 (2019/04)

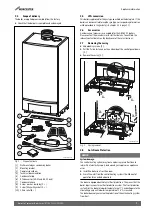

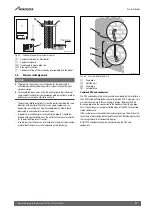

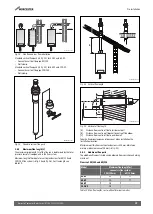

An inner flue finishing kit [1] is provided which should be fitted to the

ducts before assembly.

▶ Push the assembly through the wall and slide the terminal onto the

flue connector. Ensure that the terminal is fully entered into the

socket on the boiler.

▶ From the outside fix the flue finishing kit to the terminal and, after

ensuring the flue is properly inclined towards the boiler, fix the

finishing kit to the wall. If the terminal is within 2 m of the ground

where there is access then an approved terminal guard must be

fitted. The guard must give a clearance of at least 50mm around the

terminal and be fixed with corrosion resistant screws.

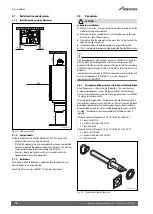

3.9

Flue gas connection

3.9.1

Open flue operation

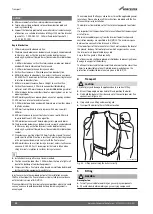

If room-sealed fluing is not desired or possible due to local conditions,

the boiler can be set up for operation to take air for combustion from the

room in an open flue arrangement (contact Worcester Technical team for

advice).

The boiler is factory-fitted with a concentric connection.

An air intake strainer basket can be used for open flue operation.

This prevents ingress from entering the boiler (contact Worcester

Technical; accessory).

3.9.2

Room sealed operation

The boiler can be connected to a concentric flue gas system.

The boiler is factory-fitted with a concentric connection.

3.9.3

Flue material

When using 3rd party plastic flue material, PPS is recommended.

3.9.4

Calculating the air intake and flue gas pipe dimensions

The total reduced pipe length is calculated from the sum of the reduced

length of the horizontal and vertical flue ducting and elbows

(

The total reduced flue length must be less than the maximum allowable

flue length (

See also the next example.

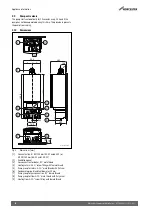

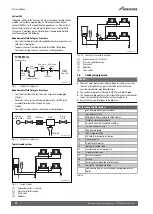

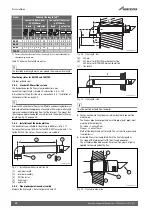

Example of a flue design calculation for concentric flue system

100/150 using equivalent length method

Boiler: GB162-85 V2

Flue system: concentric 100/150

Maximum length: 18 m.

Here we have:

• 4 metre pipe (2 x 2 m) 4.0 m

• 2 x 90° bends (2 x 2.1 m) 4.2 m

The total length of this flue system = 8.2 m

Sum of length (8.2 m) < maximum length (18 m)

acceptable flue

length.

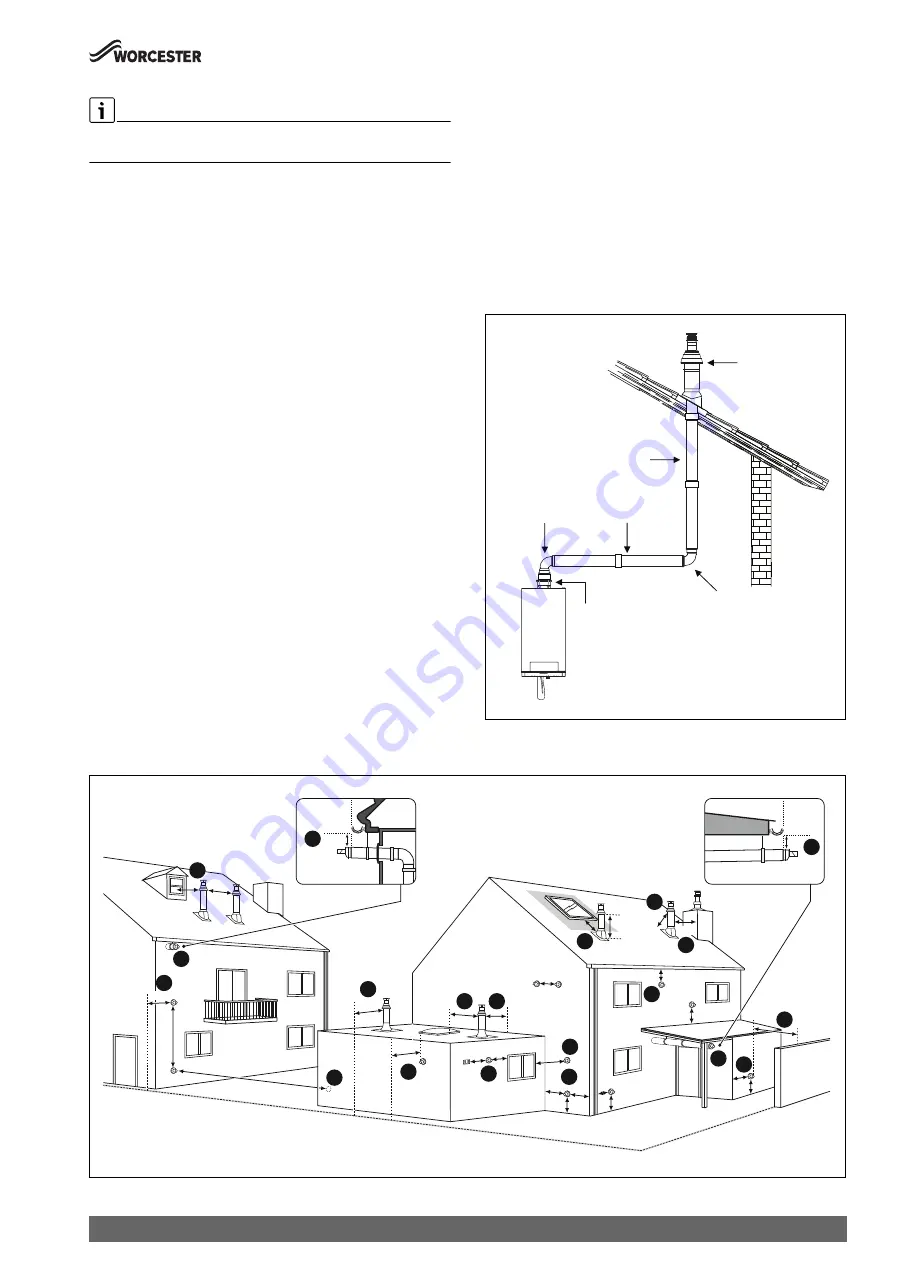

Fig. 31 Example 1

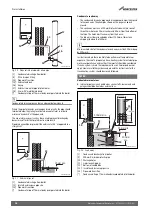

3.10

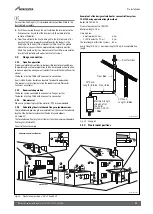

Flue terminal positions

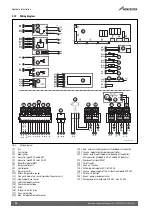

Fig. 32 Flue terminal positions - 50-V2 and 65-V2

0010026003-001

Pipe

=

2m

Pipe

=

2m

Roof terminal

90° bend

Length

=

2.1m

90° bend

Length

=

2.1m

Maximum length

allowed after

the boiler

(GB162-85 V2)

=

18m

00100

26004

-001

16

600

300

200

300

1,200

Boundary Line

1,500

1,500

All measurements in millimetres

2

1

11

10

9

5

18

7

6

15

4

3

17

14

300 300

300

300

300

300 300

500

600

300

600

300

400

300

25

8

300

500

600

300

25

2

25

16

12

13