Transport

Worcester Commercial Boiler Series – 6720814332 (2019/04)

22

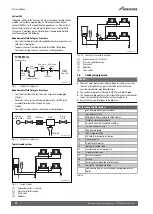

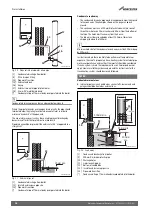

NOTICE:

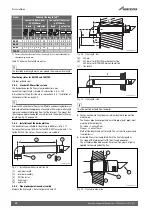

▶ All measurements are the minimum clearances required.

▶ Terminals must be positioned so to avoid combustion products

entering the building.

▶ Support the flue at approximately one metre intervals and at a change

of direction, use suitable brackets and fittings (125mm flue bracket

(pack of 3) = T-000-082-131. 150mm flue bracket (pack of 3)

= 7-716-191-102).

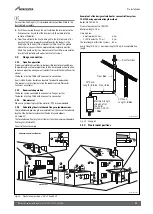

Key to illustration

1. 300mm adjacent to a boundary line.

2. The dimension below eaves, balconies and car ports can be reduced

to 25mm, as long as the flue terminal is extended to clear any

overhang. Any external flue joints must be sealed with suitable silicon

sealant.

3. 1,500mm between a vertical flue terminal and a window or dormer

window, 300mm between two flue terminals.

4. 1,200mm between terminals facing each other.

5. Vertical flue clearance, 300mm adjacent to a boundary line.

6. 600mm distance to a boundary line, unless it will cause a nuisance.

BS 5440:Part 1 recommends that care is taken when siting terminal

in relation to boundary lines.

7. 600mm minimum clearance from a skylight to a vertical flue.

8. Vertical flue clearance, 500mm to non-combustible building

material, and 1,500mm clearance to combustible building material.

9. 300mm above, below and either side of an opening door, air vent or

opening window.

10.600mm diagonally to an opening door, air vent or opening window.

11.300mm to an internal or external corner.

12.2,000mm below a Velux window, 600mm above or to either side of

the Velux window.

13.400mm from a pitched roof or in regions with heavy snow fall

500mm.

14.500mm clearance to any vertical structure on a roof, 600mm to

room sealed flue or 1,500 to an open flue.

15.200mm below eaves and 75mm below gutters, pipe and drains.

16.The dimension below eaves, balconies and car ports can be reduced

to 25mm, as long as the flue terminal is extended to clear any

overhang. Any external flue joints must be sealed with suitable silicon

sealant.

17.Flue clearance must be at least 300mm from the ground. Terminal

guards must be fitted if the flue is less than 2 metres from the ground

or if a person could come into contact with the flue terminal.

18.600mm distance to a surface facing a terminal, unless it will cause a

nuisance. BS 5440: Part 1 recommends that care is taken when

siting terminals in relation to surfaces facing a terminal.

▶ Installations in car ports are not recommended.

▶ The flue cannot be lower than 1,000mm from the top of a light well

due to the build up of combustion products.

▶ Dimensions from a flue terminal to a fanned air inlet to be determined

by the ventilation equipment manufacturer.

In instances where the combined output of the installation exceeds

70kW net heat input the flue solution must be installed in accordance

with the latest version of IGE/UP/10.

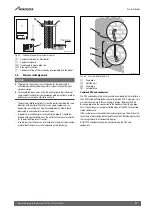

Pluming will occur at the terminal so terminal positions where this could

cause a nuisance should be avoided. Active plume management is

encouraged.

The air supply and the flue gas exhaust must meet the applicable general

regulations. Please also consult the instructions provided with the flue

terminal kits prior to installation.

The boiler must be installed so that the terminal is exposed to external

air.

It is important that the position of the terminal allows the free passage of

air at all times.

Minimum acceptable spacing from the terminal to obstructions and

ventilation openings are specified in IGE/UP/10. The minimum space

between two concentric flue terminals is 300mm.

If the lowest part of the terminal is less than 2 metres above the level of

the ground, balcony, flat roof or place to which any person has access,

the terminal must be protected by a guard.

Ensure that the guard is fitted centrally.

The flue assembly shall be so placed or shielded as to prevent ignition or

damage to any part of the building.

The flue outlet duct and the terminal of the boiler must not be closer than

25mm to combustible material. Detailed recommendations on the

protection of combustible material are given in IGE/UP/10.

4

Transport

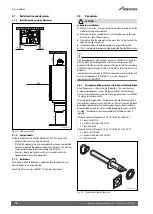

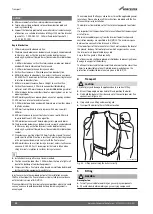

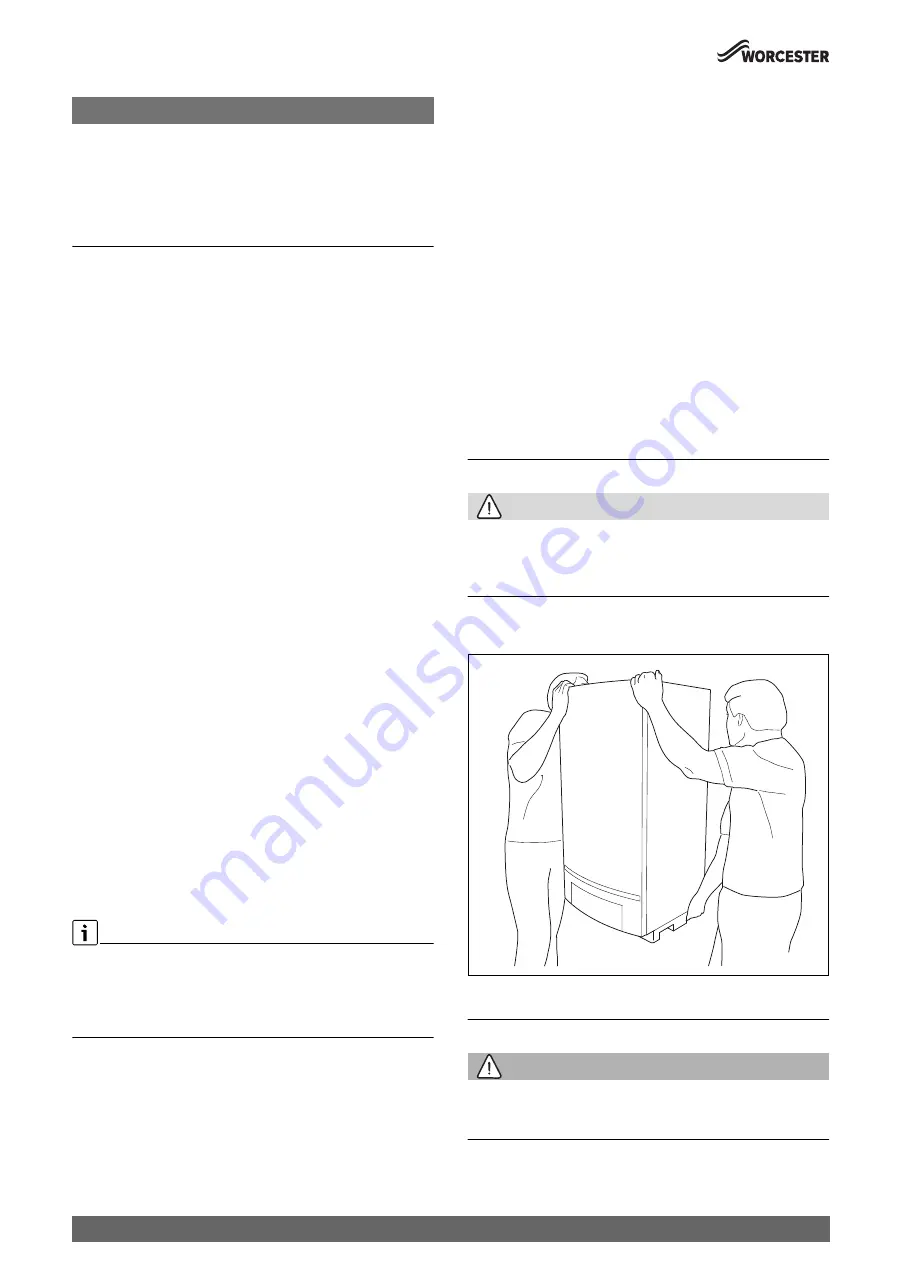

CAUTION:

Physical injury and damage to appliance due to incorrect lifting.

▶ At least two people are required to lift and position the boiler.

▶ Only hold the boiler at the sides and not at the control panel or flue

connection (

figure 33).

▶ If required, use a lifting and mounting aid.

▶ Transport the boiler to the installation location.

Fig. 33 Lifting and carrying the boiler correctly

5

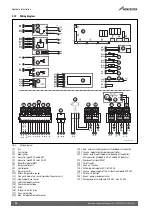

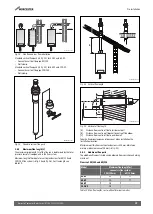

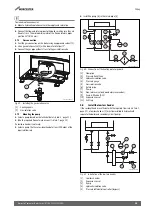

Fitting

WARNING:

Gas explosion.

▶ Turn off gas valve before working on gas-carrying components.

▶ Check for leaks before working on gas-carrying components.

0010009981-001