Fitting

25

Worcester Commercial Boiler Series – 6720814332 (2019/04)

To make maintenance easier:

▶ Mount a hydraulic isolation valve in the supply and return line.

▶ Connect the flow and return pipes to the boiler, making sure they are

free of stress. The minimum diameter of the flow and return pipes

must be 1½" (Ø 35 mm).

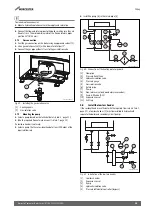

5.7.1

Gas connection

▶ Seal the gas connection on the boiler using an approved sealant [1].

▶ Use a gas isolation valve [2] with a diameter of at least 1".

▶ Connect the gas pipe without stress to the gas isolation valve.

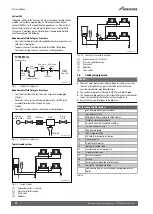

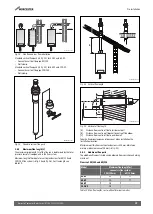

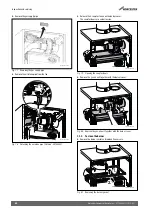

Fig. 39 Installing the gas isolation valve

[1]

Sealing agents

[2]

Gas isolation valve

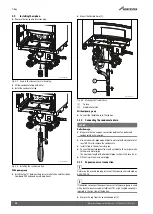

5.7.2

Mounting the pump

▶ Select a pump based on the technical data (

▶ Take the required flow rate into account (

If a low loss header is not used:

▶ Select a pump that has a residual head of at least 200 mbar at the

required flow rate.

▶ Install the pump [6] in the return pipe [5].

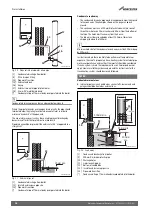

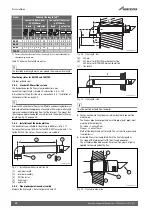

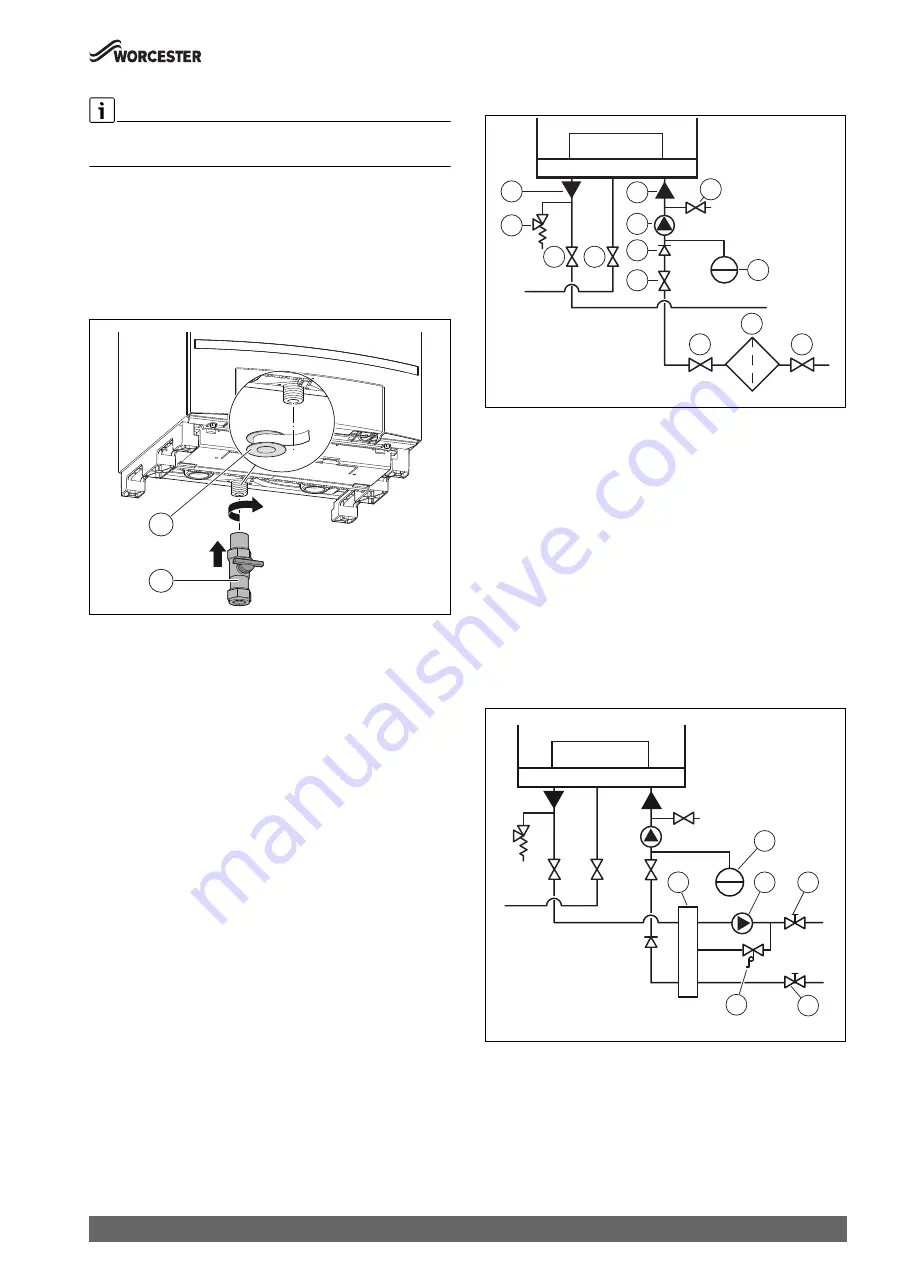

Fig. 40 Connection of the heating water pipework

[1]

Flow pipe

[2]

Pressure Relief Valve

[3]

Hydraulic isolation valve

[4]

Pressure gauge

[5]

Gas isolation valve

[6]

Return pipe

[7]

Pump

[8]

Non-return valve (only mandatory in cascades)

[9]

Drain & fill valve (DFV)

[10] Expansion vessel

[11] Dirt trap

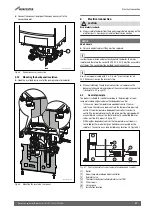

5.8

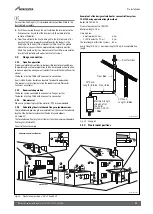

Install the low loss header

If the residual head is insufficient with the required flow rate (

page 12), a low loss header [1] must be installed to hydraulically

separate the boiler and secondary circuit pumps.

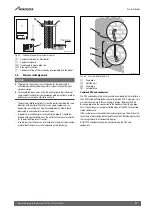

Fig. 41 Installation of the low loss header

[1]

Low loss header

[2]

Expansion vessel

[3]

Pump

[4]

Hydraulic isolation valve

[5]

Pressure differential controller (bypass)

0010009992-001

1

2

0010009994-001

8

4

3

3

3

1

5

2

6

7

3

9

10

0010020132-001

1

2

3

4

4

5