Commissioning

Worcester Commercial Boiler Series – 6720814332 (2019/04)

38

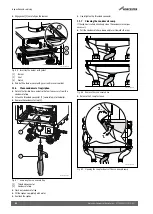

▶ Select the μA measurement value at the multi-meter.

▶ Bring the boiler into operation.

▶ Make sure that the boiler can dissipate the heat generated.

▶ Start the chimney sweep mode(

Chapter 7.3).

▶ Set the smallest possible output value in % (partial load).

▶ Measure the ionisation current.

The ionisation current must be at least 3 μA.

▶ If the value is lower, check the gas/air ratio and the monitoring

electrode.

▶ Enter the value in the maintenance protocol (

Chapter 11.15).

▶ Switch off the chimney sweep mode.

▶ Take the boiler out of operation.

▶ Remove the multi-meter.

▶ Re-connect the ionisation plugs.

▶ Bring the boiler into operation.

8.11

Testing for gas leaks

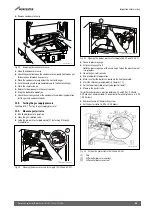

NOTICE:

Damage to the boiler due to short-circuit.

▶ When using leak detection spray, cover the plug and cables.

▶ Start the chimney sweep mode (

Chapter 7.3).

▶ As soon as the burner is on, check all gas-carrying components using

an approved gas leak detection spray.

▶ Check the rubber gasket [1] at the ignition unit and the monitoring

electrode for tightness.

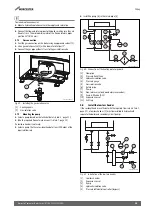

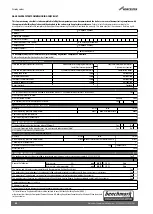

Fig. 74 Inspecting the gas train

▶ Determine the cause of a possible leak.

▶ Take steps to remedy the leak.

▶ Exit the chimney sweep mode.

8.12

Check the operating characteristics of the boiler

▶ Create a heat demand and check whether the boiler starts burning

after several minutes to support the boiler operation.

▶ If applicable: open a DHW tap and check the DHW temperature and

DHW volume.

8.13

Final steps

▶ Fit the casing.

▶ Complete the Benchmark checklist (50-V2 and 65-V2) or

commissioning report (85-V2 and 100-V2).

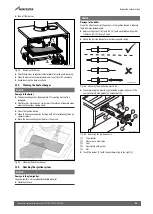

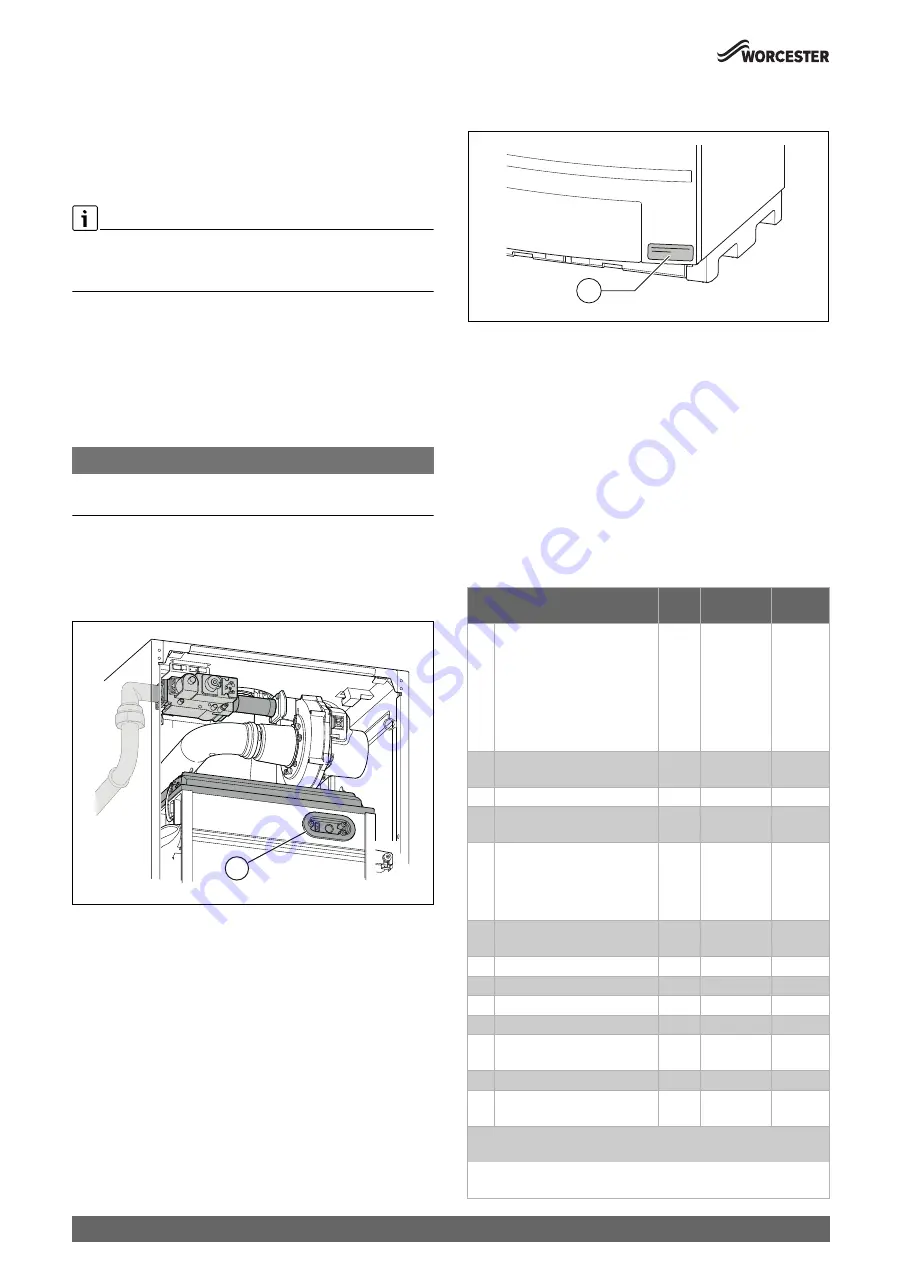

▶ Place second ID sticker [1] (part of the documentation set) at the

bottom right on the front cover.

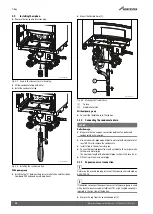

Fig. 75 Second ID sticker

8.14

Inform the user

▶ Familiarise the user with the heating system and operation of the

boiler.

▶ Explain to the user how the heating system must be filled.

▶ Point out to the user that they must not carry out conversions, repairs

or maintenance themselves.

▶ Fill out the commissioning report to confirm commissioning

(

Chapter 8.15).

▶ Hand the technical documentation to the user.

8.15

Commissioning report (for installations below

70 kW)

▶ Sign all completed commissioning work and enter the date.

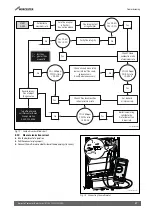

0010010037-001

1

Commissioning steps

Page

Measured

values

Remarks

1.

Filling and venting the heating

system.

• Expansion vessel pre-

charge pressure (observe

the installation instructions

for the expansion vessel)

• Heating system fill pressure

_______bar

_______bar

2.

Check gas type against the data

plate.

3.

Vent the gas line.

4.

Check the combustion air/flue

gas connection.

5.

Adjusting the boiler:

• Adjust the output

• Adjust the flow temperature

• Setting pump run-on time

6.

Measure the gas supply

pressure.

7.

Measure gas/air ratio.

8.

Measure the CO

2

content.

9.

Check the gas tightness.

10. Check the flue gas tightness.

11. Check the function of the

boiler.

12. Fitting the casing.

13. Instruct the user, hand over

technical documentation.

Confirm professional commissioning:

Company stamp/

signature/date

0010026009-001

1