Pre-Installation

Worcester Commercial Boiler Series – 6720814332 (2019/04)

14

System fill:

Filling and refilling of the heating circuit must have been carried out by a

method that has been approved by the Water Regulation Advisory

Scheme (WRAS), for the type of heating appliances, i.e. Domestic (in-

house) Fluid Category 3. Non-Domestic (other than in-house) Fluid

Category 4. Depending on the Fluid Category the approved method

should comprise of the following:

Requirements Fluid Category 3 systems:

• Control valve (stop valve) including a double check valve on the mains

cold water supply pipe.

• Temporary connection to be removed after filling (filling loop).

• Control valve (stop valve) on the heating system pipework.

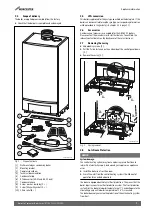

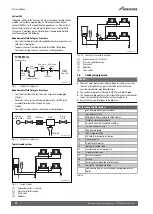

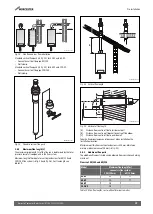

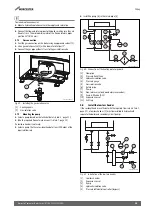

Fig. 9

System fill - category 3

Requirements Fluid Category 4 systems:

• Control valve (stop valve) on the mains cold water supply pipe.

• Strainer.

• Water non-return valve with reduced pressure Zone (RPZ valve

assembly) incorporating a Type BA air gap.

• Tundish.

• Control valve (stop valve) on the heating system pipework.

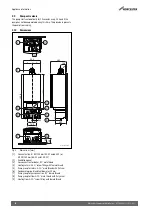

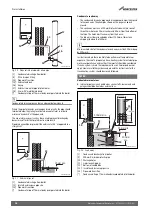

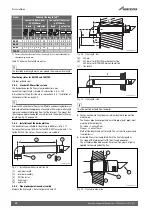

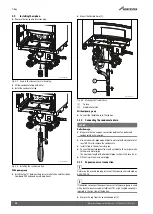

Fig. 10 System fill - category 4

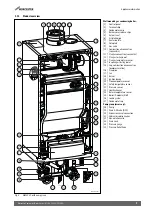

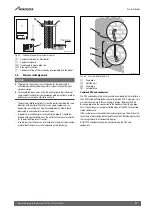

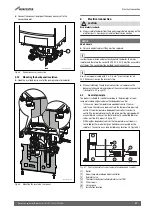

Typical sealed system

Fig. 11 Sealed system

[1]

Expansion vessel - CH return

[2]

Pressure relief discharge

[3]

Drain cock

[4]

Radiators

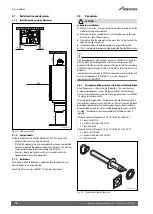

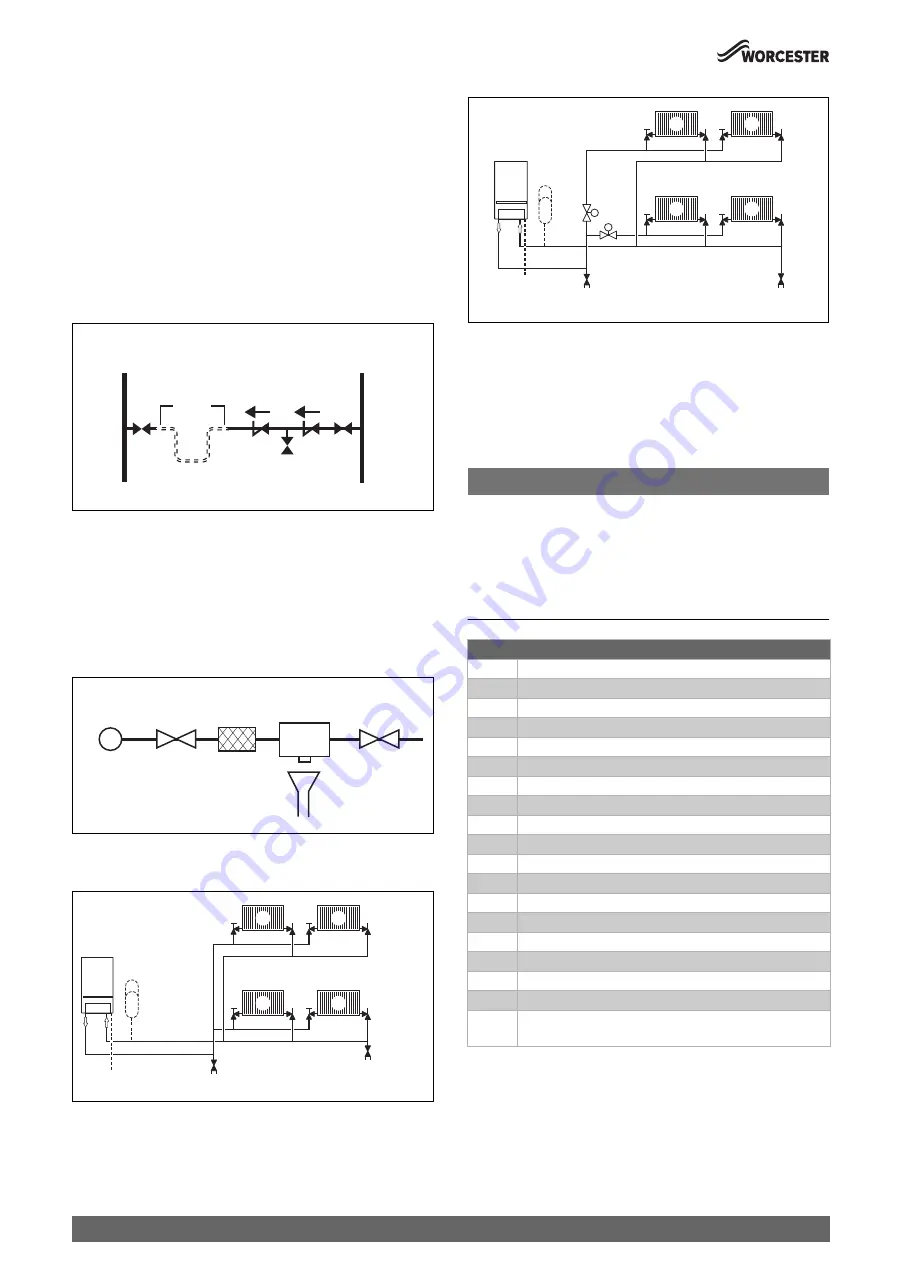

Fig. 12 Sealed system with zone valves

[1]

Expansion vessel - CH return

[2]

Pressure relief discharge

[3]

Drain cock

[4]

Radiators

[5]

Zone valves

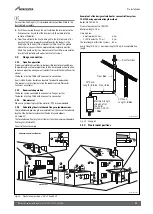

3.5

Condensate pipe work

NOTICE:

▶ Where a new or replacement boiler is being installed, access to an

internal “gravity discharge” point should be one of the factors

considered in determining boiler location.

▶ The condensate pipe must be nominally 22mm Ø plastic pipe.

▶ The condensate pipe work must fall at least 52mm per metre towards

the outlet and should take the shortest practicable route.

▶ Ensure there are no blockages in the pipe run.

Table 9

0010025981-001

Heating return

SYSTEM FILL

Hose

return

Stop

cock

Test cock

Non return

valve

Non return

valve

Mains

supply

Temporary hose

Stop cock

0010025982-001

Mains

cold water

Stop

cock

Stop

cock

Strainer

RPZ

Tundish

0010025983-001

3

3

1

2

4

4

4

4

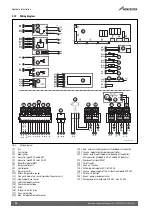

Key to condensate illustrations

1

Condensate discharge from boiler

2

Soil and vent stack

3

Minimum 450mm and up to three storeys

4

Visible air break at plug hole

5

Sink or basin with integrated overflow

6

75mm sink waste trap

7

Condensate pump

8

PVCu strap on fitting

9

100mm Ø minimum plastic pipe

10

Drainage holes

11

Limestone chippings

12

Bottom of sealed tube

13

Insulate and increase pipe size

14

Pipe work transition

15

External air break

16

Air gap

17

External rain water pipe into foul water

18

43mm 90° male/female bend

*

Condensate trap of 75mm already incorporated into the

boiler

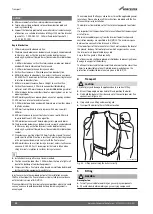

0010025984-001

M

M

3

5

3

1

2

4

4

4

4