Fitting

23

Worcester Commercial Boiler Series – 6720814332 (2019/04)

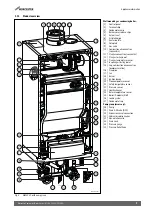

5.1

Unpacking the boiler

▶ To ensure the connections are not damaged, only remove the

styrofoam at the bottom once the boiler has been hung.

▶ Remove packaging and dispose of it.

▶ Prevent damage to the connections.

▶ Cover the connection for the flue gas/air supply on the top of the wall

mounted gas condensing boiler to prevent ingress.

5.2

Check gas type

▶ Make sure that the gas type to which the boiler is connected

corresponds to the gas type specified on the data plate (

figure 4,

[8]).

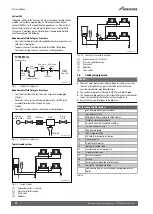

5.3

Mounting the boiler

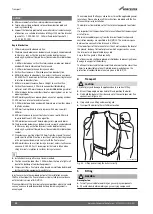

NOTICE:

Damage to appliance due to incorrect lifting.

▶ Lift the boiler with one hand underneath and the other on top of it.

The boiler may only be hung on the wall or installed on a cascade frame.

Wall-mounted installation

▶ Check whether the wall is strong enough to support the weight of the

boiler, pump group and water content.

▶ Mount a fastening structure if required.

▶ Determine the position of the boiler on the wall.

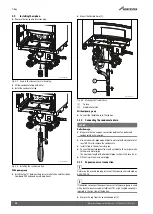

▶ Mark holes using the mounting bracket supplied (

figure 34).

▶ Install the mounting bracket on the wall with the assistance of a spirit

level.

Fig. 34 Installing the mounting bracket on the wall

▶ Hook the boiler on to the mounting bracket.

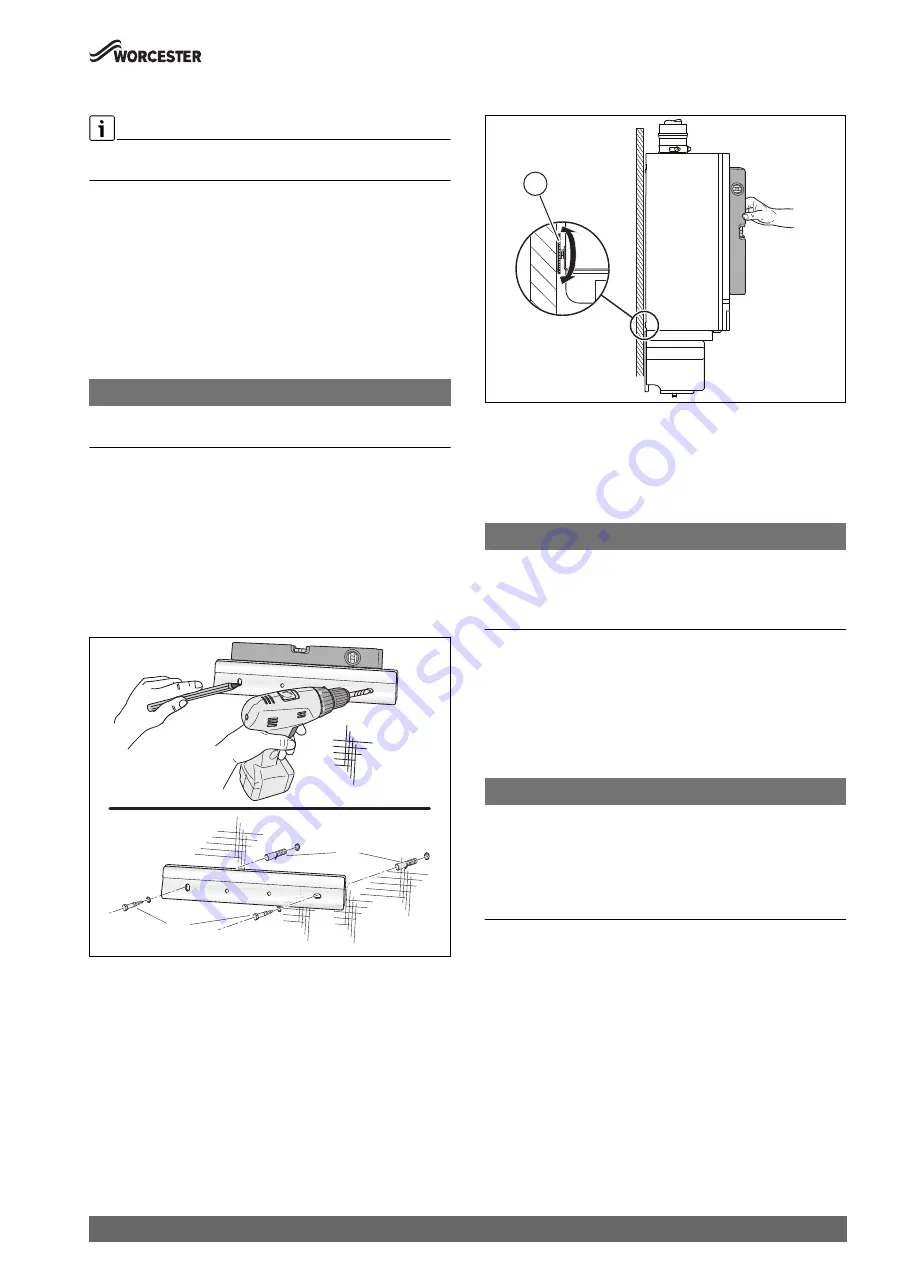

▶ Level the boiler using the set screw [1] and a spirit level.

Fig. 35 Aligning the boiler

Mounting on a cascade frame

▶ For details on mounting the boiler in a cascade frame, see the

installation instructions for the cascade system.

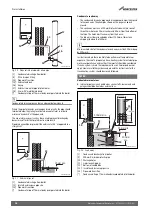

5.4

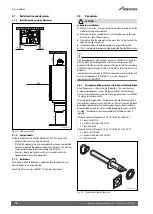

Remove the protective caps

NOTICE:

Water damage.

The boiler may contain water. This can be discharged when the caps are

removed.

▶ Keep a bucket and cloth handy.

▶ Take the caps off the connections on the underside of the boiler.

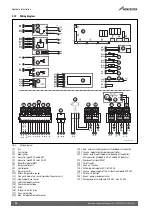

5.5

Hydraulic and gas connections

There are 2 ways to make the hydraulic and gas connections:

• Using the pump group (accessory) (

chapter 5.6)

• Without using the pump group (

chapter 5.7).

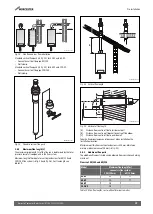

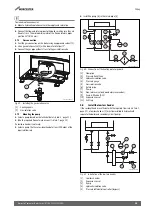

5.6

Mounting the pump group (accessory)

NOTICE:

Installation damage.

The pump group includes a pressure relief valve.

▶ Check whether the excess pressure, the operating pressure and

components in the heating system suite each other.

▶ If necessary, replace the PRV with a PRV of appropriate excess

pressure. Maximum boiler pressure is 4 bar.

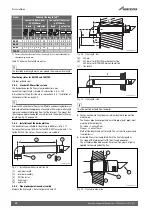

The following components have been incorporated into the pump group:

• Gas isolation valve

• Flow and return isolation valves

• Pressure gauge

• Thermometer

• Pressure Relief Valve

• Pump

• Drain & fill valve (DFV)

0010009982-001

1.

2.

3.

4.

0010009984-001

1