Inspection and maintenance

59

Greenstar 4000 – 6 720 891 161 (2020/09)

▶ Re-check the fan pressure readings.

If the appliance, after completing the above checks, fails the fan

pressure test then contact Worcester, Bosch Group for advice.

▶ Switch the appliance off after completing pressure check.

▶ Disconnect the digital manometer and replace the test point cover.

8.4

Check working gas inlet pressure

NOTICE

Gas inlet pressure

▶ Do not continue with the other checks if the correct gas inlet pressure

can not be achieved at maximum output.

▶ Check the gas supply working pressures in the system conform to the

readings shown in the table shown in chapter 6.5 "Checking gas inlet

pressure".

8.5

Flue gas analysis

NOTICE

Combustion testing

▶ Combustion testing must be carried out by a competent person.

Testing must not be attempted unless the person carrying out the

combustion check is equipped with a calibrated flue gas analyser

conforming to BS 7967 and is competent in its use.

Flue gas analysis

▶ Ensure that the gas inlet pressure has been checked and is

satisfactory.

▶ Refit the test point plugs after the test has been completed.

▶ Set the appliance to maximum and minimum output in chimney

sweep mode (

6.4 "Chimney sweep mode") for the flue gas

analysis checks.

▶ Check that the readings conform to those given in the following

tables. In addition to CO and CO/CO

2

ratio checks also check the

maximum and minimum CO

2

percentage reading.

CO/CO

2

settings

Table 30 CO

2

settings

If the CO

2

is out of tolerance then please check:

▶ The gas inlet pressure.

▶ The gas rate.

▶ The fan test pressure.

▶ The flue and air intake, plus any possible blockages in the condensate

disposal.

▶ The condition of burner.

▶ For leaks or obstructions in the exhaust paths.

▶ That the injector is clean.

After all checks have been completed and the CO

2

is still out of tolerance

then contact Worcester, Bosch Group helpline 0330 123 3366 before

making any adjustment to the gas valve.

8.6

Checking the flue integrity

NOTICE

▶ Check flue joints are secure, the terminal and the terminal guard, if

fitted are clear and undamaged.

▶ Combustion testing must be carried out to BS 7967 by a competent

person. Testing must not be attempted unless the person carrying

out the combustion check is equipped with a calibrated Combustion

Analyser conforming to BS EN 50379 and is competent in its use.

Flue gas analysis

▶ Ensure that the gas inlet pressure has been checked and is

satisfactory.

▶ Refit the test point plugs after the test has been completed.

▶ Refer to chapter 6.9 "Checking flue integrity" and check that the

readings conform to those given, confirming flue system and

combustion circuit are ok.

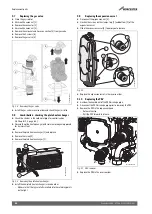

8.7

Cleaning the siphon and heat exchanger

8.7.1

Checking the electrodes and cleaning the heat exchanger

CAUTION

Risk of burns due to hot surfaces!

Individual components of the appliance can become very hot even after

being shut down for a long time.

▶ Allow the appliance to cool down before carrying out any work.

▶ If necessary, wear protective gloves.

WARNING

Material damage due to hot flue gas! - Gaskets and seals - gas related

components

Hot flue gas can leak through defective gaskets, damage the appliance

and endanger safe operation.

▶ Burner/electrode assembly gasket must be replaced if disturbed.

▶ Other gaskets/seals must be checked and replaced where necessary.

▶ Do not attempt the cleaning procedure unless new gaskets and seals

are available.

▶ Ensure that the gaskets are positioned correctly.

NOTICE

Material damage due to chemicals

Using chemicals during the cleaning of the heat exchanger assembly and

associated parts or carrying out maintenance can damage the sealing

components. This can cause exhaust gas to escape during operation.

▶ Do not use chemicals to flush the heat exchanger assembly and

associated gas carrying components.

CO

2

Reading

CO Reading

Natural Gas appliances

Maximum rated Output

1)

1) Should be measured 10 minutes after firing the appliance

Between 9.0 and 9.8%

<250ppm

Minimum rated Output

1)

A minimum of 0.2 lower than the maximum reading

taken and between 8.2 and 9.0%

<250ppm

LPG appliances

Maximum rated Output

1)

Between 10.4 and 11.0%

<250ppm

Minimum rated Output

1)

A minimum of 0.2 lower than the maximum reading

taken and between 10.0 and 10.4%

<250ppm