Prepare for operation

7

Greenstar 8000 Style – 6720883869 (2018/05)

3

Prepare for operation

3.1

Open vented heating system

Appliances that can be connected to open vented heating systems will

have the pressure maintained automatically by the header tank feeding

the system.

3.2

Sealed heating system

Appliances that can be connected to sealed heating systems are pre-

pressurised before operation, this pressure must be maintained for safe

use of the appliance.

▶ Check regularly that the pressure is maintained.

▶ Re-charge the system if the pressure gauge reads less than 1 bar.

▶ If a permanent significant decrease or increase in pressure is

indicated on the pressure gauge, contact your installer or

maintenance engineer.

3.2.1

Checking the system pressure

If the pressure is too low (≤ 0.2 bar) the system is out of operation and a

warning notification stays on the screen. Fill the water until indicator is in

green zone.

Your installer will advise you of the optimum operating pressure.

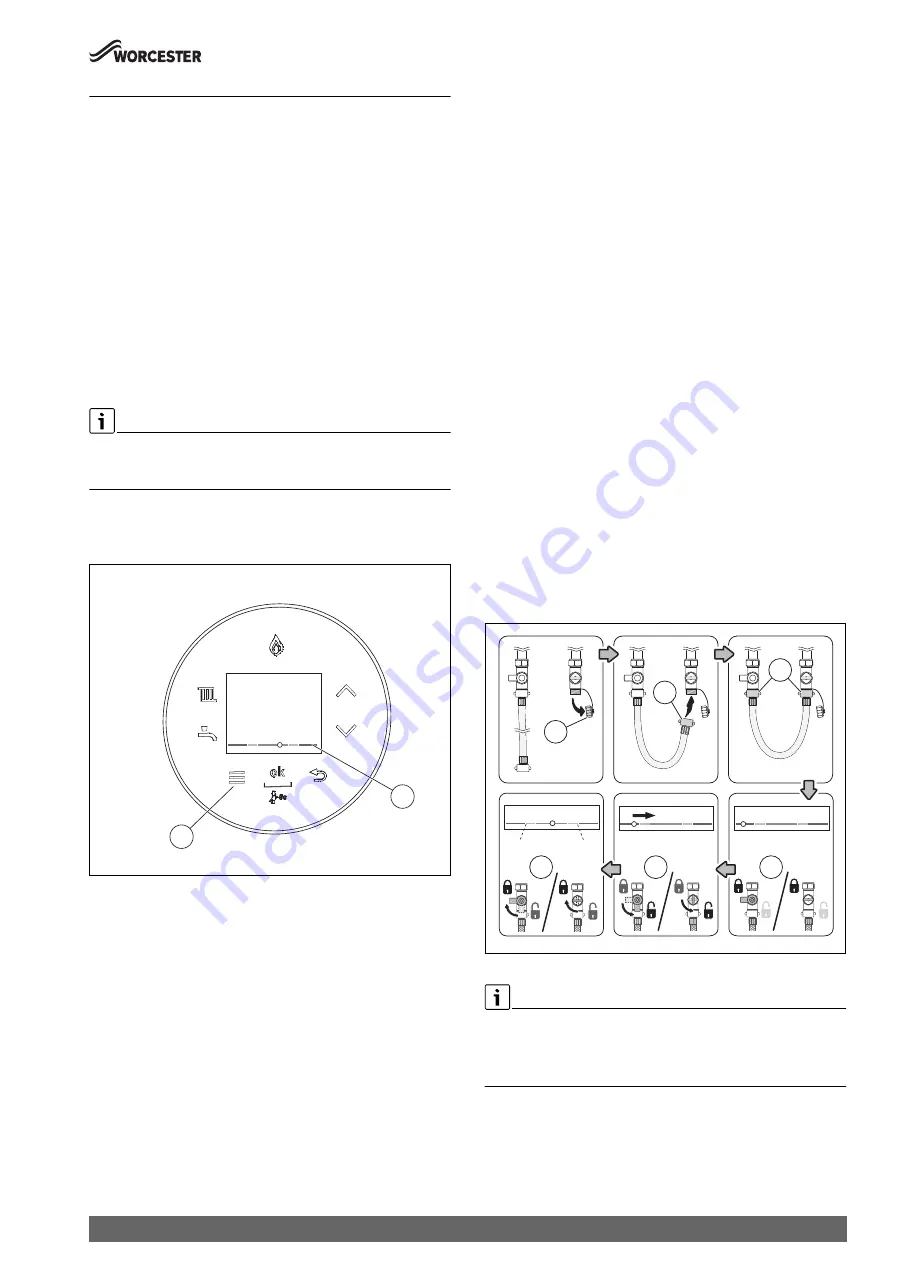

▶ Press the menu key [1]. Select and confirm

Boiler status

.

The screen

Boiler status

with a pressure indicator [2] appears.

Fig. 2

Pressure indicator for checking the operating pressure

▶ Check the system pressure at the display.

–

Indicator in red zone

: pressure is too low or too high.

–

Indicator in yellow zone

: pressure is low or slightly too high.

–

Indicator in green zone:

pressure is normal.

▶ Top up the heating water, if the pressure is low or too low.

3.2.2

Constantly re-pressuring the system pressure

Constantly having to re-pressuring the heating system should be

investigated as the concentration of inhibitor protection in the system

will be reduced; this can result in corrosion within the heating system

reducing the efficiency and increasing contaminates.

▶ Check for leaks on heating system (pipe work and radiator valves).

▶ Contact your installer or maintenance engineer if a recurring

significant decrease or increase in pressure is indicated on the

pressure screen.

3.3

Topping up the system pressure

External filling loop

Once the external filling loop and pressure display has been located,

follow the instructions for re-pressurising the system.

▶ Unscrew the blanking cap [1].

▶ Attach the hose [2] to the valve.

– Usually one end of the hose is already connected to one of the

system fill isolation valves.

▶ Ensure both ends [3] of the hose are screwed on hand tight.

▶ Monitor the pressure display.

– The system fill isolation valves [4] are in a closed position (the

handle/screwdriver slot is across the valve).

▶ Turn the handle/screwdriver slot through 90° to open valves and

slowly fill the system.

– The system fill isolation valves [5] are opened (the handle/

screwdriver slot is in-line with the valve).

– The pressure indicator on the pressure bars will start to move

towards the green bar.

▶ Set the pressure between 1 and 1.5 bar pressure.

Pressure indicator is on the green bar.

▶ Turn the handles/screwdriver slots back, through 90°, to close the

valves.

– The system fill isolation valves [6] are in a closed position (the

handle/screwdriver slot is across the valve).

▶ Top up the system pressure, if as a result of the air bleeding the

pressure drops off.

Once the pressure has settled between 1 and 1.5 bar.

▶ Ensure the valves are closed.

▶ Remove the hose [2] and replace the blanking cap [1].

Fig. 3

If the indicator is on the right hand side red pressure zone as a result of

over filling:

▶ Bleed one radiator until the pressure indicator returns to the green

bar.

0010022943-001

1

2

0010022967-001

1

2

3

4

5

6

Min

Max