STARTING AND STOPPING THE HYBRID SYSTEM

6 720 803 688 (2012/11)

7

4

STARTING AND STOPPING THE HYBRID

SYSTEM

The specified sequences and delays must always be observed when

starting and stopping the hybrid system. Otherwise the hybrid system

components could suffer severe damage.

4.1

STOPPING THE HYBRID SYSTEM

Switching off the hybrid system:

▶ Reset any current heat demands using the programming unit.

▶ After stopping the operation, wait at least 5 minutes. Only then isolate

the power supply to the hybrid manager and the external unit.

Otherwise, water leakage or breakdown may result.

4.2

ENSURING FROST PROTECTION

4.3

RESTARTING THE HYBRID SYSTEM AFTER AN

INTERRUPTION IN OPERATION

4.4

SETTING UP HEATING MODE

Make the following adjustments on the condensing boiler or on the

FW200 programming unit:

• Maximum flow temperature

With underfloor heating systems observe the maximum permissible flow

temperature. Older underfloor heating systems generally require higher

flow temperatures than more modern systems.

• Maximum DHW temperature

• Setback mode

• Summer mode

• Frost protection

4.5

SETTING HYBRID SYSTEMS

4.5.1

OVERVIEW OF THE CONTROL MODES

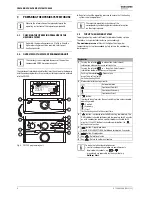

Symbols

Current room temperature

Flashing segment:

Current time (

09:30

to

09:45

)

Solid segments:

Time set for operating mode

= Comfort today (1

segment = 15 min)

Empty segments:

Time set for operating mode

= Economy today (1

segment = 15 min)

No segments:

Time set for operating mode

= Frost today (1 segment =

15 min)

Operating mode Comfort for heating circuit

Operating mode Economy for heating circuit

Operating mode Frost for heating circuit

Automatic mode for heating circuit

Holiday mode

Burner operation on display for heating circuit

+

Scroll menu/info text up

or increase value

–

Scroll menu/info text down

or decrease value

OK

Open menu, confirm setting/value or switch heating circuit

Return to next menu up

Delete/reset value

Bring forwards the next switching time and the associated

operating mode

= Comfort

= Economy

= Frost

for the heating circuit to now.

Activate DHW heating immediately. The DHW cylinder is

heated to the required temperature for 60 minutes or, with

combi boilers, comfort mode is activated for 30 minutes. If

the ECO button is active for combi boilers, the

button has no function.

The hybrid control module regulates the times the air to

water heat pump and the condensing boiler are in use,

subject to the parameters entered into the FW200

programming unit.

▶ Never isolate the power supply to the hybrid manager

and the external unit during standard operation.

9

21

15

3

advance

advance

advance

NOTICE:

Frost damage

When the heating system is switched off, it can freeze up

if there is a frost.

▶ In the case of a risk of frost, have the DHW circuit

drained by an a competent person or mix antifreeze

that is approved for use with the respective

condensing boiler into the heating water.

Whether antifreeze may be used and which type is

permissible depends on the installed condensing boiler.

▶ Observe the details in the condensing boiler

installation instructions.

NOTICE:

Damage to the external unit from low operating

temperature.

When restoring the power supply following an

interruption of operation.

The Power supply to the external unit must be ‘live’ for at

least 12 hours before starting operation. This is to

ensure that the compressor is warmed up sufficiently to

avoid any liquid refrigerant from entering the

compressor. This is particularly important during colder

periods.

The 12 hour period also compensates for any unsettling

of the lubricating oil within the compressor which may

have occurred during transportation.

If this 12 hour time period cannot be met damage to the

outdoor unit may result.

▶ If the appliances fail to start contact your installer.

The separate operating instructions of the condensing

boiler or the FW200 programming unit include

information on the steps required.

These parameters can be set either via the FW 200

weather-compensated controller or via the hybrid

control module. These values are transferred and

overwritten respectively. The following section will

describe how to make the settings using the FW 200

weather-compensated controller.