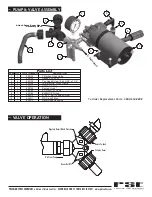

PowerFLO

™

7800 Series

12 Volt DC Motor-Driven Diaphragm Pumps

Specifications —

Motor:

Type: 12 VDC, permanent magnet, totally enclosed, non-ventilated

Leads: 18 AWG, 12” long

Duty Cycle: See Heat Rise graph

Temperature Limits: Motor is not equipped with thermal

protection. For user safety, optimal performance, and

maximum motor life, the motor surface temperature should

not exceed 150°F (66°C) (see Heat Rise graph above right).

Pump:

Type: 3 chamber positive displacement diaphragm pump, self

priming, capable of being run dry, demand or bypass model.

Certifications: NSF Standard 58

Liquid Temperature: 140°F (60°C) Max.

Priming Capabilities: 14 feet (4 m)

Max Pressure: 60 PSI

Inlet/Outlet Ports: 7802: Quick Attach

Materials of Construction:

Housing: Polypropylene Diaphragm: Santoprene

Valves: Viton

Fasteners: Stainless steel

Weight:

6 lbs (2.7 kg)

Installation and Operation Precautions —

1. The pump is equipped with a pressure sensing demand switch that

controls the maximum operating pressure.

2. In addition, never subject the pump to pressures above 125 PSI

(8.5 bars).

3. As long as there is inlet water pressure, the pump will not stop

forward flow of water even if the motor is turned off. Be sure the

system has positive means of shutting off water supply.

4. Do not operate pump in an explosive environment. Arcing from the

motor brushes, switch or excessive heat from an improperly cycled

motor may cause an explosion.

5. Do not locate the pump motor near low temperature plastics or

combustible material. The surface temperature of the motor may

exceed 250°F (120°C).

6. Do not pump gasoline or other flammable liquids. Pump head

materials are designed for use with water only. Do not use with

petroleum products.

7. Do not assume fluid compatibility. If the fluid is improperly

matched to the pumps’ elastomers, a leak may occur.

8. To prevent electrical shock, disconnect power before initiating any

work. In the case of pump failure, the motor housing and/or pump

fluid may carry high voltage to components normally considered

safe. Therefore, always consider electrical shock hazard when

working with and handling electrical equipment. If uncertain,

consult an electrician. Electrical wiring should only be done by a

qualified electrician per local and state electrical codes.

Pressure Sensing Demand Switch —

The PowerFLO Series 7800 pump is controlled by a built-in pressure

sensing demand switch. When a faucet or valve is opened down stream of

the pump, line pressure drops thus starting the pump automatically.

Conversely, when the valve shuts, the line pressure increases turning the

pump off automatically. The pressure switch actuates in response to the

pump outlet pressure at a predetermined and preset pressure. The pump

label indicates the predetermined ON and OFF pressures. Typically, the OFF

pressure is accurately set at the Factory and the ON pressure is within an

allowable range below that value. In response to the characteristics of the

system in which the pump is installed, the flexibility and length of the

tubing, the faucet or valves and the duration that they are open; these

pressure settings may vary. Therefore, variation in pressure setting is

expected with use and over time.

Adjusting the Pressure Switch:

Should the pressure switch OFF setting vary with use and time to an

unsuitable value, it may be adjusted for optimum performance. Turn the

setscrew clockwise to increase the OFF pressure setting and counter

clockwise to decrease. The screw should not be adjusted more than one

half turn without consulting the Factory. Excessive adjustment of the

pressure switch could cause low system pressure, rapid cycling ON/OFF

operation, and reduced pump and motor life. Damage may occur. The

Warranty does not cover improper adjustment of the pressure switch.

Servicing —

Every Year: Check system against operating standards.

Every 2-3 Years: We recommend replacing the diaphragm and

checking against operating standards.

* Important return safety instructions:

When you return your pump for warranty or repair, you must always do the

following:

1. Flush chemical residue from the pump (best done in the field).

2. Tag pump with type of chemicals having been sprayed.

3. Include complete description of operation problem, such as how pump

was used, symptoms of malfunction, etc. Since pumps can contain

residues of toxic chemicals these steps are necessary to protect all the

people who handle return shipments, and to help pinpoint the reason for

the breakdown.

Model: 7802: 2.0 GPM

PRECISION SPRAY EQUIPMENT, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.grnleafinc.com

a division of Green Leaf, Inc

®

P R E C I S I O N S P R AY E Q U I P M E N T

PSE