PSE-PRECISION SPRAY EQUIPMENT

®

, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.green-leaf.us 800-654-9808

a division of Green Leaf, Inc

®

P R E C I S I O N S P R AY E Q U I P M E N T

PSE

®

®

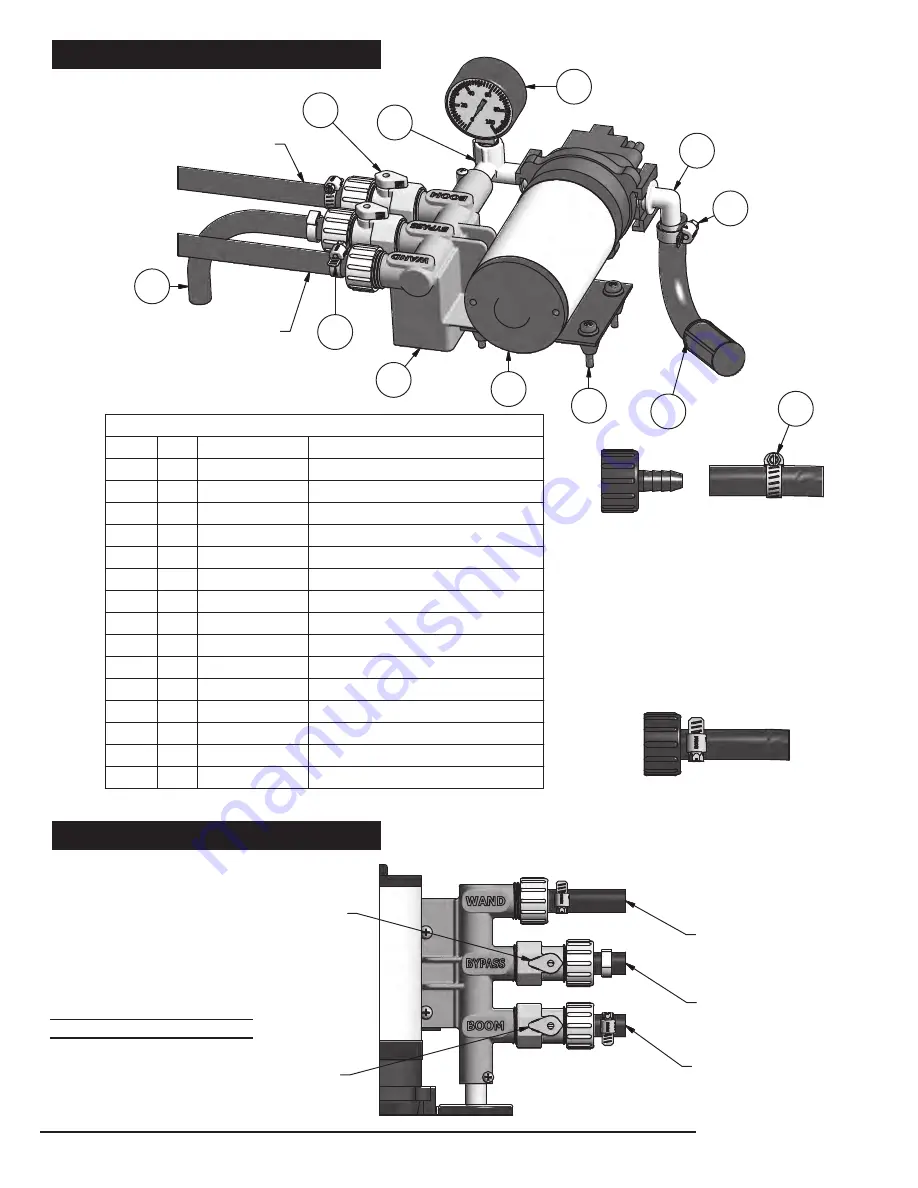

Pump & Valve Illustration

Valve Operation

View looking down on the

top of the valve assembly

PARTS LIST

DESCRIPTION

PART NUMBER

QTY

ITEM

2.2 GPM Pump

*

640451

1

1

4.0 GPM Pump

*

630201

1

1

5.0 GPM Pump

*

630031

1

1

Manifold Body

600289

1

2

Elbow (2.2 pumps)

600291

1

3

Elbow (4.0 & 5.0 pumps)

600292

1

3

Gauge 0-100 PSI

600129

1

4

Inline Valve

600216

2

5

QD EL 12

600287

1

6

5/8" Hose Clamp

600120

2

7

1/2" Hose Clamp

600288

1

8

10-24 x 1.25 Screw

600130

4

9

Relief Hose Assembly

600213

1

10

Suction Hose Assembly

600315

3

11

Cap Assembly (not shown)

600298

1

12

Wand Hose Assembly

Relief Hose Assembly

Boom Hose Assembly

if equipped

The Lever adjusts the system pressure by

relieving liquid back to the tank. Adjusting

this lever will increase or decrease pressure

to both the spray wand and the spray boom.

The lever turns the spray

boom on and off

Install Wand Hose Assembly onto

Swivel Barb Assembly, by placing a

Hose Clamp over the open end of the

hose on the Wand Hose Assembly.

Then pressing the open end of the

hose onto the Swivel Barb Assembly

like shown. Secure in place by

tightening the Hose Clamp as shown.

7

Wand Hose Assembly

Boom Hose Assembly

1

1

4

3

2

0

5

6

8

1

9

7

1

*Pump included depends upon model purchased.

Summary of Contents for ATV 25BL

Page 8: ......