— GENERAL INFORMATION

— WARRANTY / PARTS / SERVICE

— OPERATION

WARNING:

Some chemicals will damage the pump valves if allowed to soak untreated for a long period of time.

Always flush the pump with water after use. Do not allow chemicals to sit in pump for extended times of idleness.

Follow chemical manufacturers instructions on disposal of all waste water from the sprayer.

— AFTER SPRAYING

— WINTER STORAGE

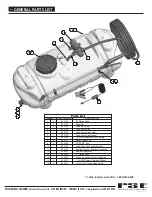

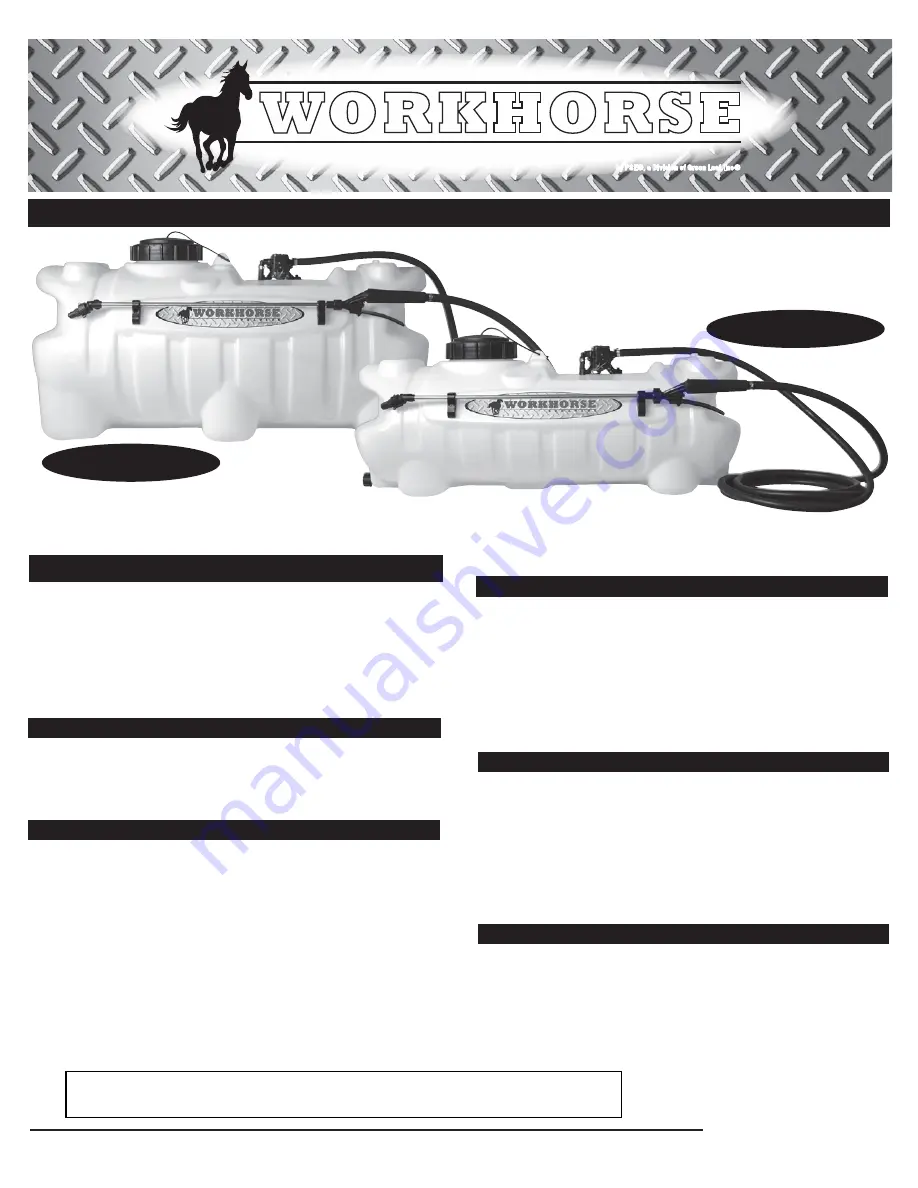

25 & 15 GAL. ECONOMY SPOT SPRAYER

MODEL # LG25 ESS and LG15 ESS

Products are warranted for one year from date of purchase against

manufacturer or workmanship defects.

Your authorized dealer is the best source of replacement parts and

service. To obtain prompt, efficient service, always remember to give

the following information:

1) Correct part description and part number.

2) Model number of your sprayer.

Part description and part numbers can be obtained from the

illustrated parts list section of this manual.

Whenever you need parts or repair service, contact your distributor /

dealer first. For warranty work always take your original sales slip, or

other evidence of purchase date, to your distributor / dealer.

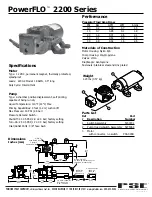

The pumping system draws solution from the tank, through the

strainer and to the pump. The pump forces the solution under

pressure to the spray wand.

The pump has a pressure switch which will shut the pump off when it

reaches 40 PSI.

Regularly inspect the suction supply screen on the inside of the tank.

Flush with water to clear any accumulated debris.

*These sprayers are designed to be attached to a stable surface.

The purpose of this manual is to assist you in assembling, operating

and maintaining your lawn and garden sprayer.

Please read it carefully as it furnishes information which will help you

achieve years of dependable trouble-free operation.

After use, fill the sprayer part way with water. Start the sprayer and

allow clear water to be pumped through the plumbing system and out

through the spray wand.

Refill the tank about half full with plain water and use a chemical

neutralizer such as Nutra-Sol® or equivalent and repeat cleaning

instructions. Flush the entire sprayer with the neutralizing agent.

Follow the chemical manufacturer’s disposal instructions of all wash

or rinsing water.

Drain all water and chemical out of sprayer, paying special attention

to pump and valves. These items are especially prone to damage

from chemicals and freezing weather.

The sprayer should be winterized before storage by pumping a

solution of RV antifreeze through the entire plumbing. Proper care

and maintenance will prolong the life of the sprayer.

• Polyethylene Tank

• 12 Volt Diaphragm Pump

• 1.0 G.P.M.

• Lever Handgun

• 15 Ft. of 3/8” Hose (Handgun)

Assembly / Operation Instructions / Parts

LG15 ESS

LG25 ESS

PRECISION SPRAY EQUIPMENT, a divison of Green Leaf, Inc. 9490 N BALDWIN ST FONTANET, IN 47851 www.grnleafinc.com 800-654-9808

a division of Green Leaf, Inc

®

P R E C I S I O N S P R AY E Q U I P M E N T

PSE

®

WORKHORSE

WORKHORSE

S P R A Y E R S

by PSE®, a Division of Green Leaf, Inc®

by PSE®, a Division of Green Leaf, Inc®

®